Method for treating organic wastewater through synergistic activation of persulfate using electrochemistry and Ni-Fe-LDH/rGO catalyst

A technology for activating persulfate and organic wastewater, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. Reduced effect, decreased activation ability, etc., to achieve the effect of reducing processing cost, good magnetic properties and stability, and enhancing catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

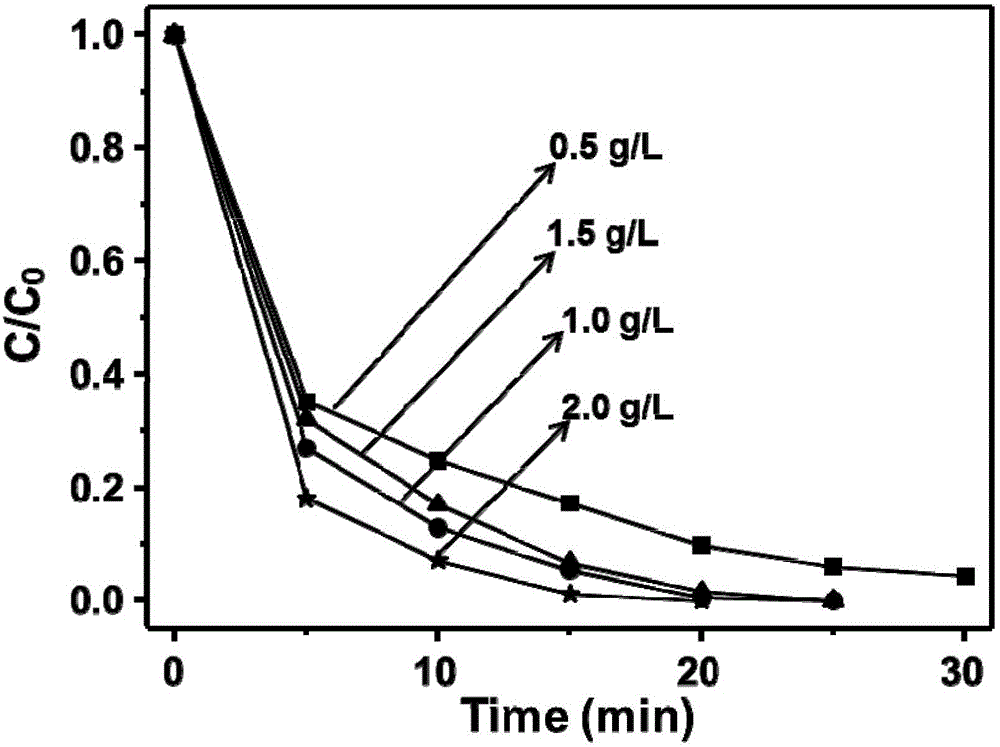

[0025] Effect of Ni-Fe-LDH / rGO Catalyst Dosage on RhB Removal Efficiency

[0026] Test conditions: the concentration of RhB is 20mg / L; the initial pH is 6.8; the dosage of oxidant is 1.0g / L; the current density is 19.53mA / cm2 ; The dosage of Ni-Fe-LDH / rGO catalyst was 0.5g / L, 1.0g / L, 1.5g / L and 2.0g / L respectively.

[0027] Experimental results such as figure 1 shown. The results showed that the degradation effect first increased and then remained unchanged with the increase of catalyst dosage, and the optimal dosage of Ni-Fe-LDH / rGO catalyst was 1.0g / L.

Embodiment 2

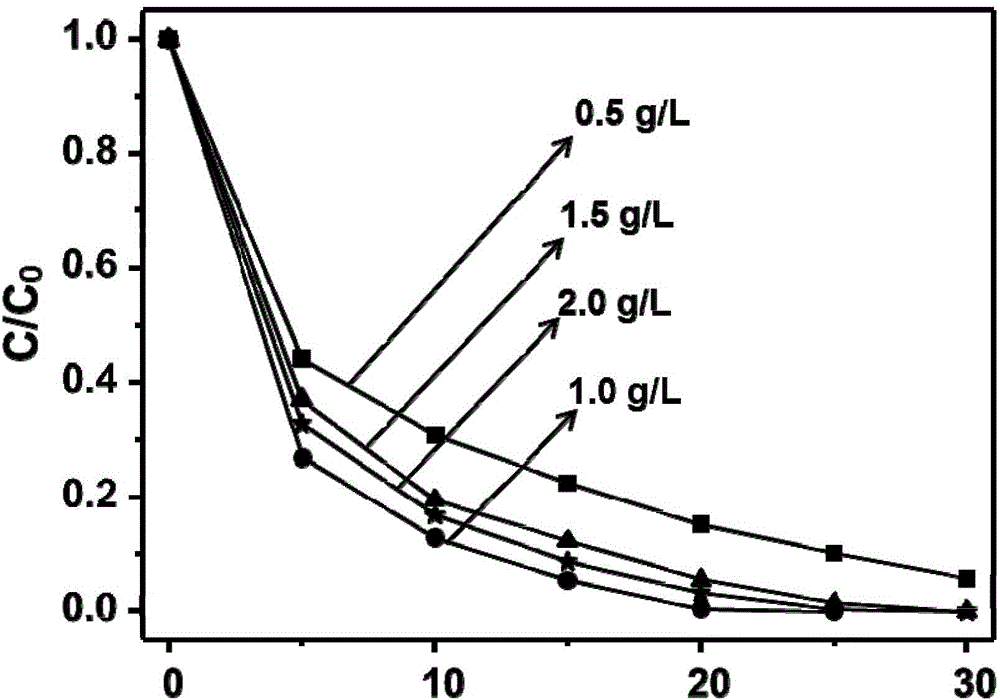

[0028] The influence of embodiment 2 oxidant dosage on RhB removal effect

[0029] Test conditions: the concentration of RhB is 20mg / L; the initial pH is 6.8; the dosage of Ni-Fe-LDH / rGO catalyst is 1.0g / L; the current density is 19.53mA / cm 2 ; The dosage of oxidizing agent is respectively 0.5g / L, 1.0g / L, 1.5g / L and 2.0g / L.

[0030] Experimental results such as figure 2 shown. The results showed that the degradation effect showed a trend of first increasing and then decreasing with the increase of the dosage of oxidizing agent, because excessive oxidizing agent would consume the produced sulfate radicals to reduce the degradation effect, therefore, the optimum dosage of oxidizing agent was 1.0 g / L.

Embodiment 3

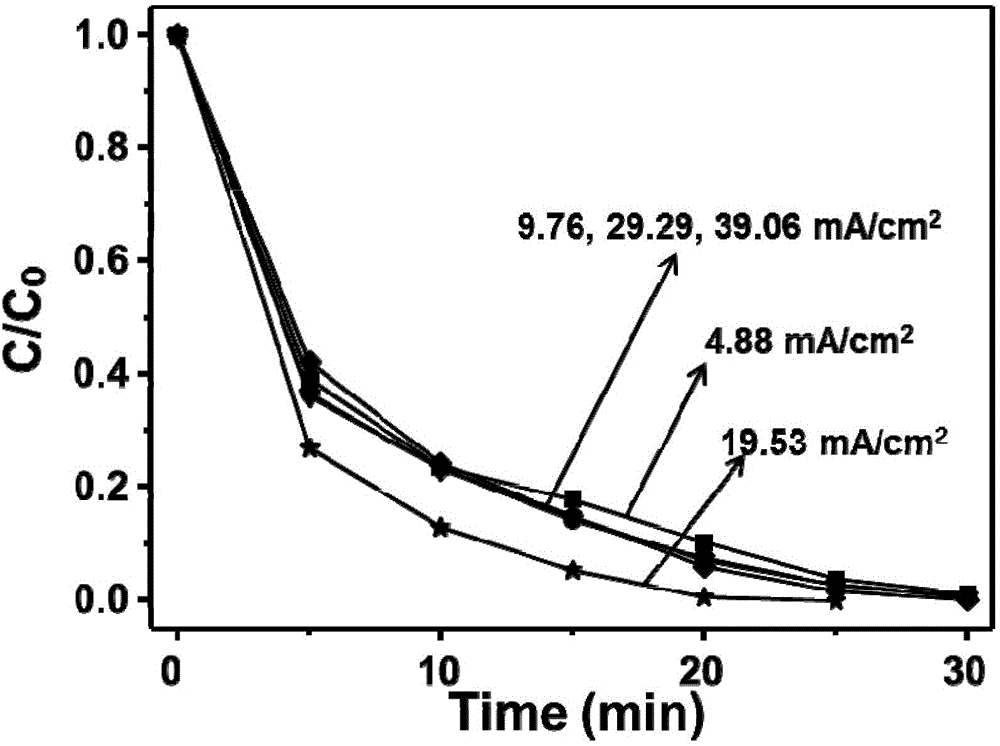

[0031] The influence of embodiment 3 current density on RhB removal effect

[0032] Test conditions: the concentration of RhB is 20mg / L; the initial pH is 6.8; the dosage of Ni-Fe-LDH / rGO catalyst is 1.0g / L; the dosage of oxidant is 1.0g / L; the current density is 4.88mA / cm 2 、9.76mA / cm 2 、19.53mA / cm 2 、29.29mA / cm 2 and 39.06mA / cm 2 .

[0033] Experimental results such as image 3 shown. The results showed that the degradation effect showed a trend of first increasing and then decreasing with the increase of current density, and too high current density would cause side reactions, resulting in the evolution of hydrogen gas at the cathode. Therefore, the optimum current density is 19.53mA / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com