Method for preparing multielement transition interface cooperative-reinforced nickel base composite material by 3D printing

A technology of 3D printing and transition interface, applied in the direction of additive processing, additive manufacturing, process efficiency improvement, etc., can solve the problems of strict three-dimensional shape requirements, complex forming process, etc., and achieve improved resource utilization, enhanced integration, and increased hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

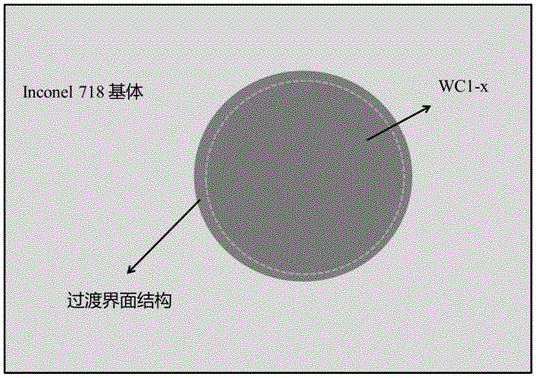

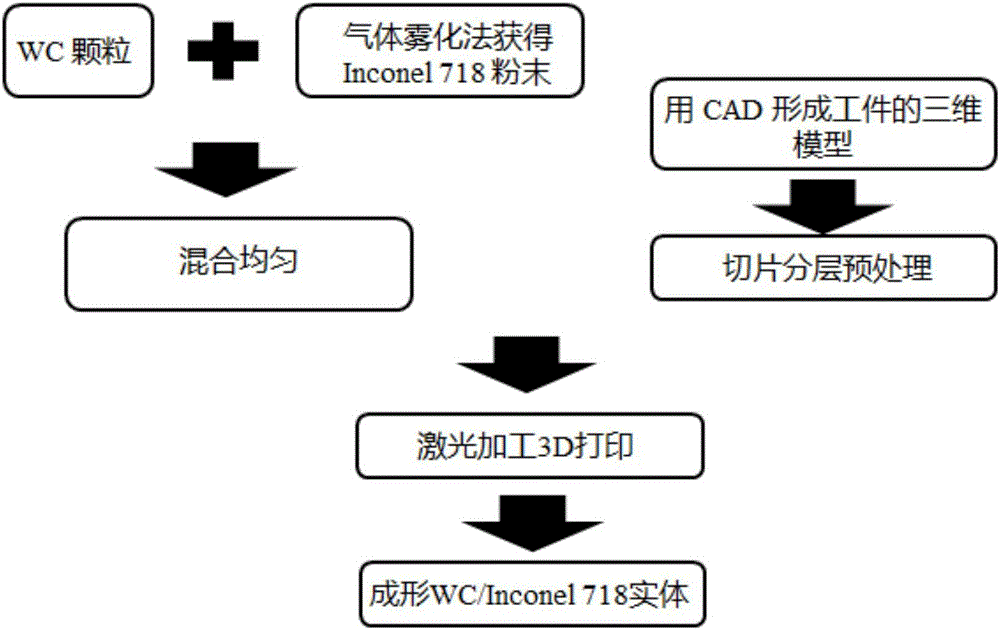

[0048] Such as figure 1 As shown, the 3D printing method of the present invention to prepare a multi-element transition interface synergistically reinforced nickel-based composite material comprises the following steps:

[0049] (1) The powder of Inconel718 was obtained by gas atomization method, the purity of which was above 99.6%, and the average particle size was 30-50 μm. Mix WC particles with an average particle size of 10-30 μm with the above-mentioned Inconel718 powder, and the weight ratio of the two is 1:3;

[0050] (2) The WC / Inconel718 mixed powder obtained above is formed by laser processing and 3D printing technology. Firstly, use CAD software to establish a three-dimensional model of the required workpiece on the computer, and slice and layer it to obtain a series of two-dimensional layered planes. Then, use the powder coating device of the laser processing 3D printing equipment to send the powder to the forming substrate, and the thickness of the powder coatin...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that the scanning velocity V is set to 960 mm / s, and the laser energy linear density η is 125 J / m, and the others are the same as Embodiment 1.

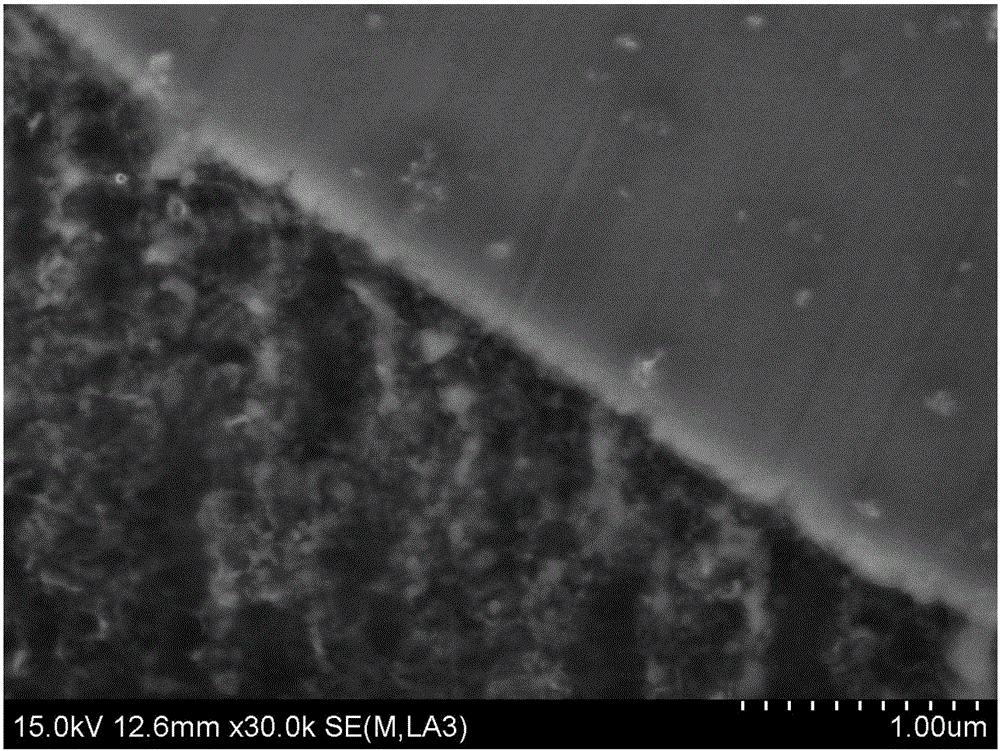

[0055] Figure 4 The microstructure photo of the nickel-based composite material obtained in Example 2 of the present invention; according to the contents of the diagram, it can be seen that no obvious multi-element transition interface is formed when the laser energy line density is 125J / m (less than 150J / m) structure.

Embodiment 3

[0057] The difference between this embodiment and Embodiment 1 is that the scanning velocity V is set to 800 mm / s, and the laser energy linear density η is 150 J / m, and the others are the same as Embodiment 1.

[0058] Figure 5 This is the microstructure photograph of the nickel-based composite material prepared in Example 3 of the present invention; according to the illustration, it can be seen that when the laser energy line density is 150J / m, a multi-element transition interface structure is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com