A closed fuel cell hydrogen source system

A fuel cell, closed technology, applied in fuel cells, hydrogen, circuits, etc., can solve the problems of poor integration of hydrogen production systems, low emission requirements, and low energy utilization, achieving smooth operation and improving energy utilization. , the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

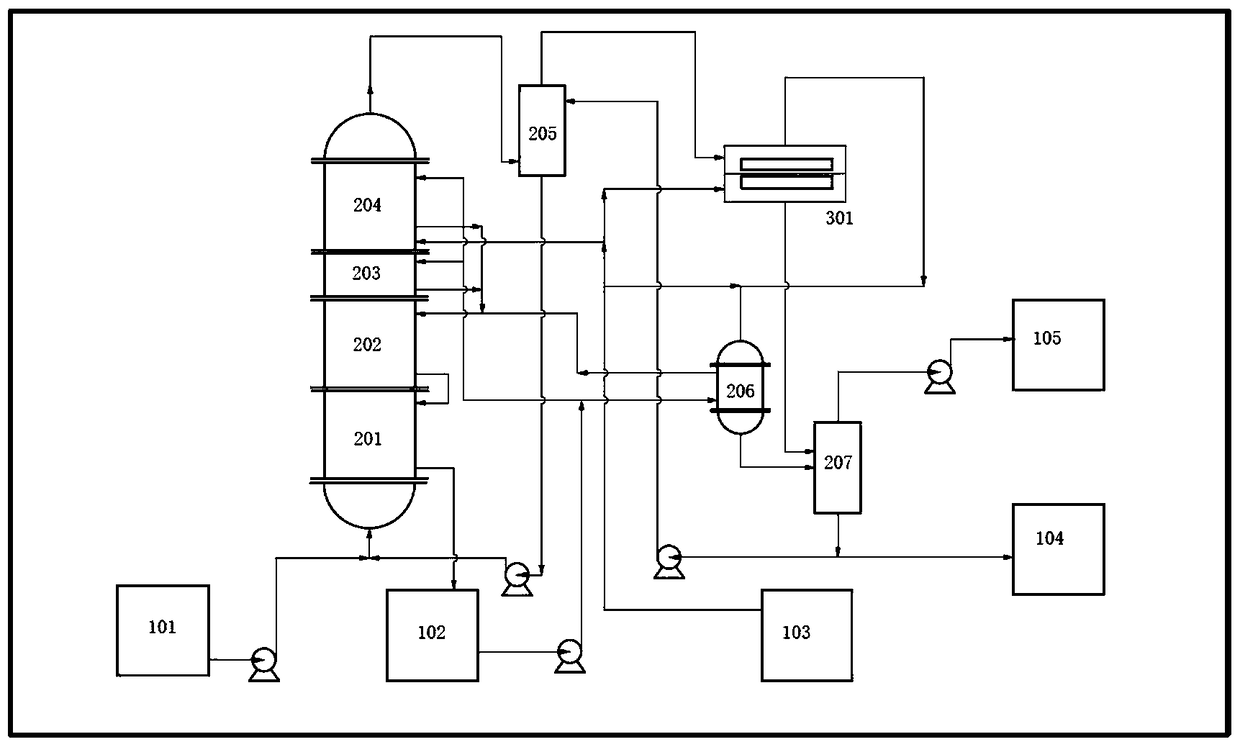

[0043] This embodiment provides a closed fuel cell hydrogen source system, characterized in that: the closed fuel cell hydrogen source system includes a methanol supply device, a liquid oxygen device, a carbon dioxide storage device, a water storage device, and a heat transfer oil storage system and methanol hydrogen production system;

[0044] Among them: the methanol hydrogen production unit includes a combustion evaporator, a reformer, a burner, a carbon monoxide selective oxidation reactor and other auxiliary systems; the overall module of the burner, reformer, evaporator and CO selective oxidation reactor change;

[0045] The inlets of the methanol supply device, the liquid oxygen device and the methanol hydrogen production device are communicated; the inlet and outlet of the heat transfer oil storage system are communicated with the methanol hydrogen production device; the carbon dioxide storage device and the liquid water storage device are respectively connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com