Method for preparing tungsten functional coating on tantalum surface at low temperature

A functional and coating technology, applied in coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of unsuitable tungsten coating on tantalum surface, high energy consumption, high preparation temperature, and overcome corrosion resistance. Poor performance, the effect of overcoming brittleness and improving the degree of densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

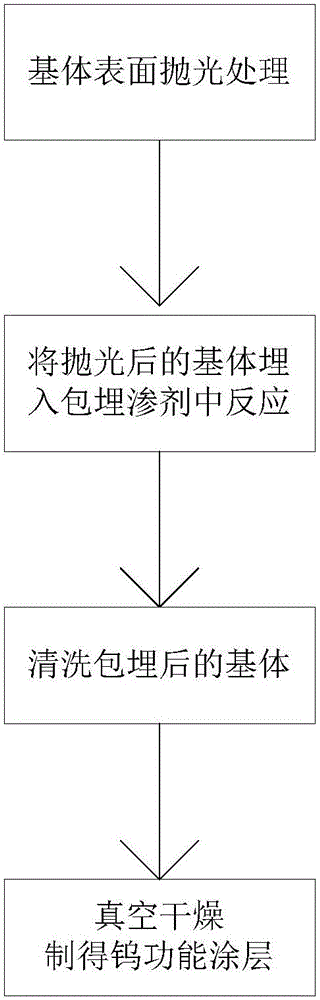

[0034] Please refer to figure 1 , a method for preparing a tungsten functional coating on a tantalum surface at a low temperature, comprising the following steps:

[0035] S1, polishing the surface of the substrate, the substrate includes tantalum, tantalum alloy or a combination thereof;

[0036] S2, embedding the polished matrix in an embedding agent for reaction, wherein the embedding temperature is 240-280°C, and the holding time is 1-8h. The embedding agent includes uniformly dispersed WCl6 powder, activator and Al2O3 powder, and the WCl6 powder ratio in the embedding infiltration agent is 30-50wt.%;

[0037] S3, after the heat preservation is completed, the embedded matrix is cleaned and vacuum-dried.

[0038] Using the embedding method, the matrix is embedded in the embedding agent for reaction, and the embedding agent includes uniformly dispersed WCl 6 powder, activator and Al 2 o 3 pink. Diffusion reaction occurs between matrix and embedding agent at 240-280...

Embodiment 2

[0047] The specific ratio of embedding penetrating agent is WCl 6 : 40wt.%, NaF or NH 4 Cl: 15wt.%, Al 2 o 3 : 45wt.%. During the embedding reaction, the temperature of the heat preservation is 280° C., and the heat preservation time is 2 hours.

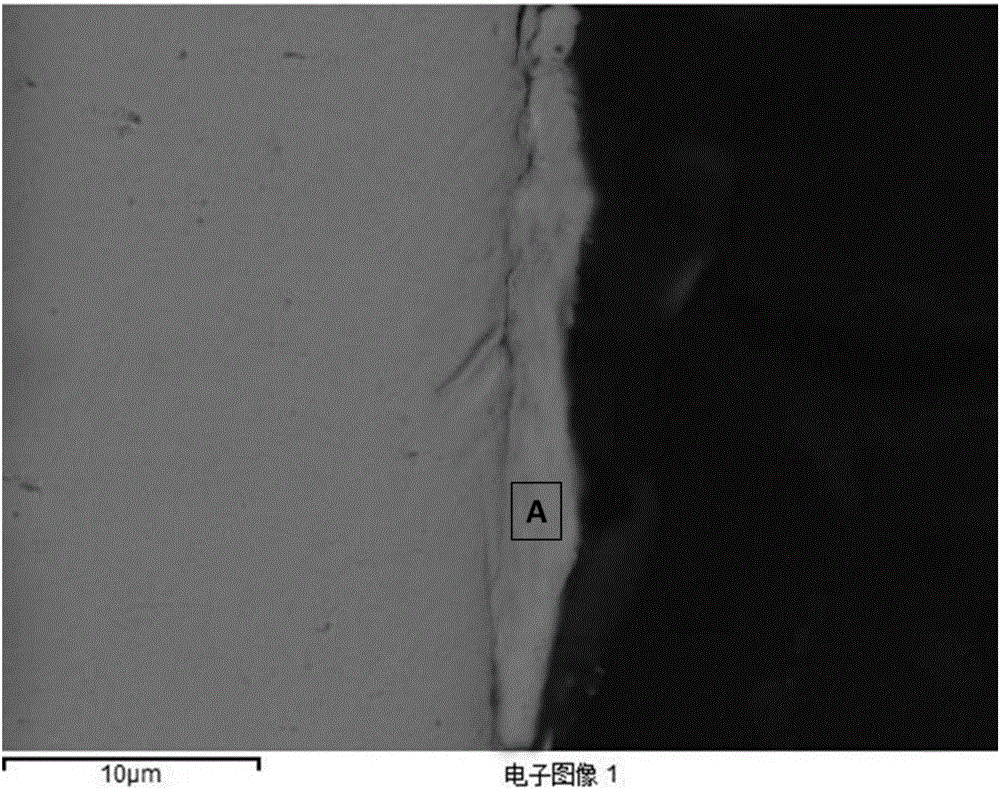

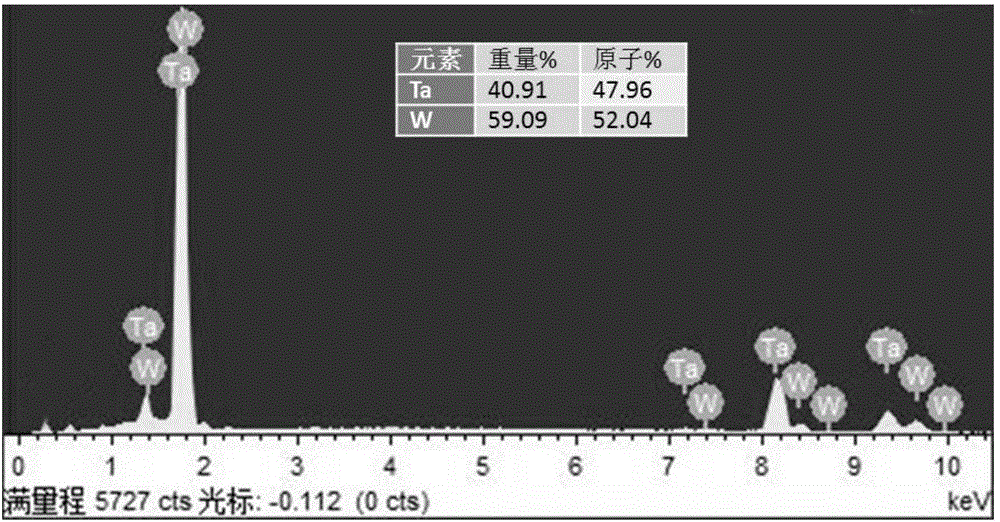

[0048] Such as Figure 2 to Figure 3 , in the prepared substrate, the tungsten functional coating is closely combined with the substrate, without holes or cracks. Such as image 3 As shown, the spectrum on the side close to the substrate surface figure 1 In the treatment, the weight ratio of metal tungsten reached 59.09wt.%, which shows that the infiltration effect of tungsten element is very good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com