Block copolymer and method and application for forming microphase separation perpendicular phase domain structure

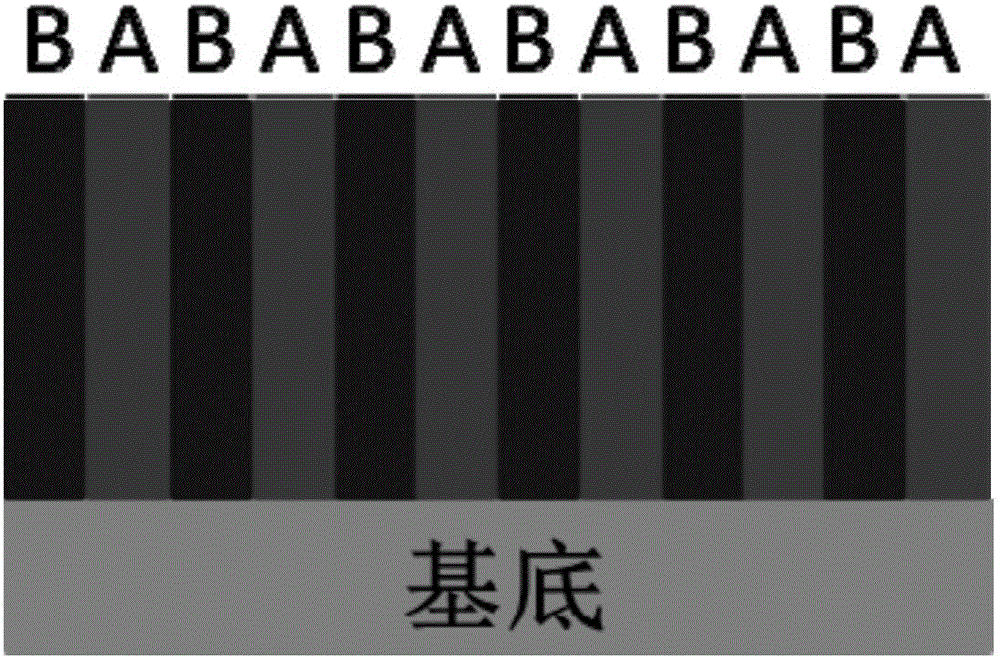

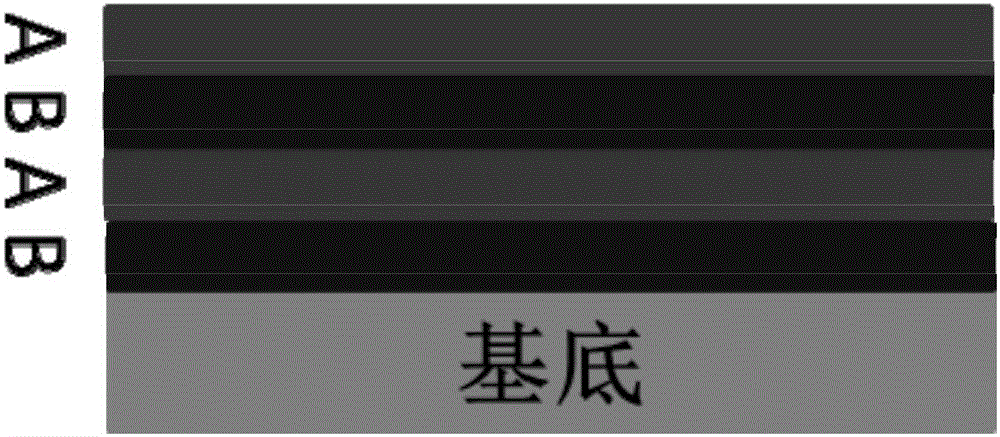

A technology of block copolymer and microphase separation, which is applied in the photolithographic process, instrument, optics and other directions of the pattern surface, and can solve the problems that cannot meet the technical requirements, the difference in surface free energy is too large, and the thermal annealing process cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of AB type polystyrene-polypropylene carbonate (PS-b-PPC) block copolymer is as follows:

[0040] Styrene (PS-OH, number average molecular weight 10700, 0.05mmol) with hydroxyl groups at the end was added to the copolymerization reaction system of carbon dioxide (2.0Mpa) and propylene oxide (2g, 34mmol), in the metal coordination catalyst SalenCoCl, Under the catalysis of 0.025mmol, the copolymerization reaction of carbon dioxide and propylene oxide undergoes chain transfer, and a chain growth reaction occurs on the hydroxyl group at the end of polystyrene. After 72 hours of reaction, the reaction is stopped, and the polymerization reaction solution is precipitated with methanol and the catalyst is washed away. And homopolymer, obtain AB type polystyrene-polypropylene carbonate block copolymer (PPC number average molecular weight is 12800).

[0041] 5 milligrams of AB type polystyrene-polypropylene carbonate (PS-b-PPC) block copolymers are dissolv...

Embodiment 2

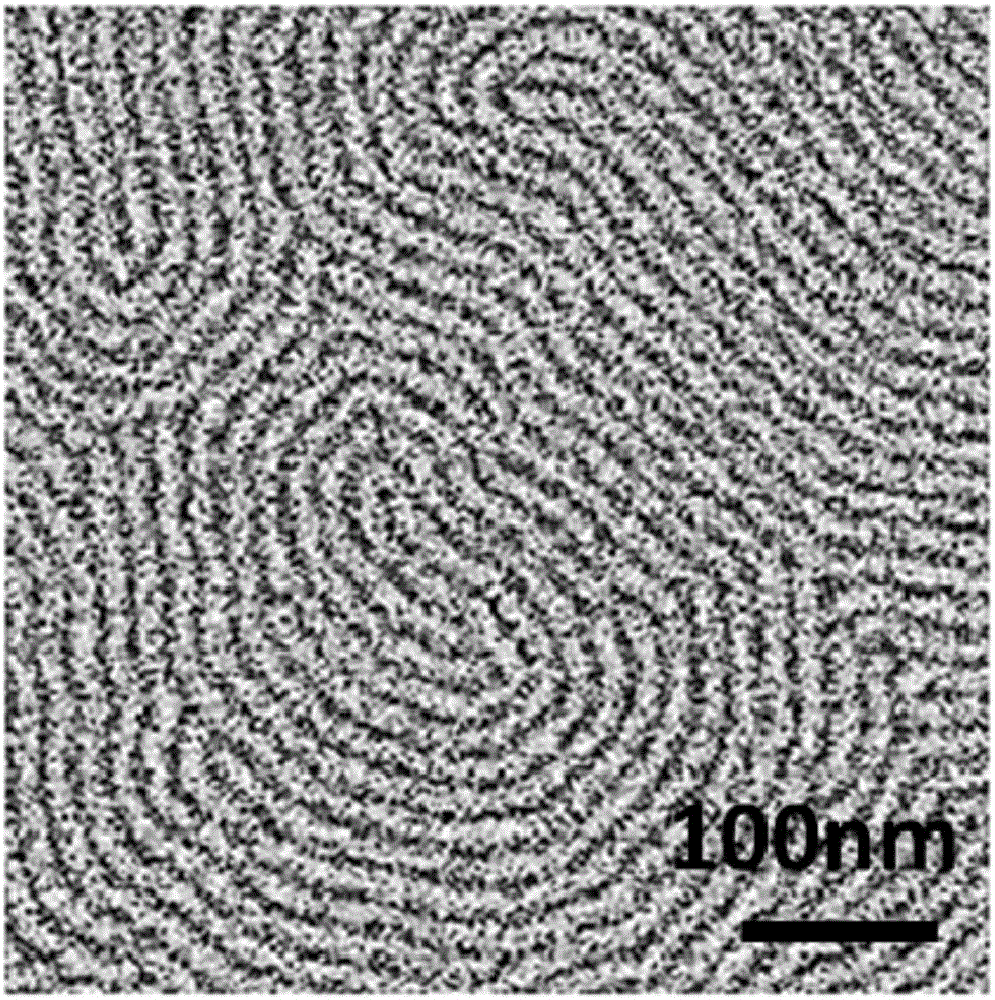

[0044] Under the same preparation method, equipment, polymer and operating conditions as in Example 1, only the condition of thermal annealing at 130° C. for 12 hours under vacuum was changed to thermal annealing at 180° C. for 1 minute under nitrogen atmosphere. attached by Figure 4 It can be seen from the scanning electron microscope pictures shown that the phase domain arrangement perpendicular to the surface of the silicon wafer is obtained, and the half-pitch reaches 8.5nm.

Embodiment 3

[0046] The preparation method of AB type polystyrene-polypropylene carbonate (PS-b-PPC) block copolymer is as embodiment 1.

[0047] 5 milligrams of AB type polystyrene-polypropylene carbonate (PS-b-PPC) block copolymers are dissolved in 0.5 g of chlorobenzene, wherein PS number-average molecular weight is 10700, PPC number-average molecular weight is 12800, carbonate The unit content was 99%, and the molecular weight distribution was 1.01. Spin-coat the complete PS-b-PPC chlorobenzene solution to the silicon wafer with a cycle of 84nm linear patterns at a speed of 4000 rpm, (84nm linear patterns can be obtained by photolithography or electron beam etching, etc. Preparation by means commonly used in the world, such as the photolithography technology and nano-pattern preparation method used in the reported literature Nature2003, 424, (6947), 411-41 and Science, 2008, 321, 936), to obtain a block with a film thickness of about 25nm polymer film.

[0048] Thermal annealing at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com