A preparation method of polymer microfluidic chip based on hydrogel 3D printing

A technology of microfluidic chip and 3D printing, which is applied in processing and manufacturing, manufacturing auxiliary devices, processing data acquisition/processing, etc., and can solve problems such as polymer microfluidic chips that have not yet been discovered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

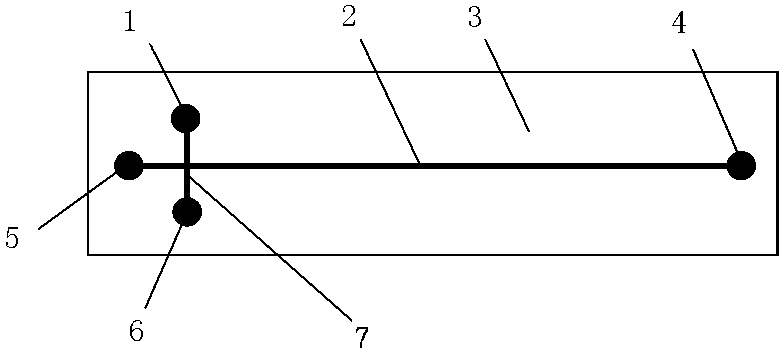

[0041] Example 1. Application of 3D printed carrageenan hydrogel positive mold in the preparation of polymethyl methacrylate microfluidic chip

[0042] First, it is necessary to prepare carrageenan thermoreversible hydrogel for 3D printing, which mainly contains water, cross-linking agent potassium chloride and carrageenan. The formula of carrageenan hydrogel: 1.5% carrageenan, 1% potassium chloride cross-linking agent, and the balance of water. Weigh 15 grams of carrageenan powder and disperse it into 800 grams of water, and swell at room temperature (about 25°C) for 6 hours. Then, heat to 95°C to completely dissolve the carrageenan. Dissolve 10 grams of potassium chloride in 175 grams of water, mix evenly with heated carrageenan solution, degas under negative pressure, cast into strips with a diameter of 3-8 mm, and store in a refrigerator at 4°C. The above formula was obtained through a series of optimization experiments, mainly by adjusting the concentration of the hydro...

Embodiment 2

[0049] Example 2, Application of 3D printed agar hydrogel positive mold in the preparation of polydimethylsiloxane microfluidic chip

[0050] The design of the microfluidic chip and the manufacturing method of the agar hydrogel positive mold are the same as in Example 1.

[0051] Mix 77 grams of water with 2.5 grams of agar powder and let the agar swell for 3 hours. Then, heat to 90°C to completely dissolve the agar. Dissolve 0.5 g of borax in 20 ml of water, mix the two solutions while hot, and cool to room temperature to obtain a 3D printing hydrogel.

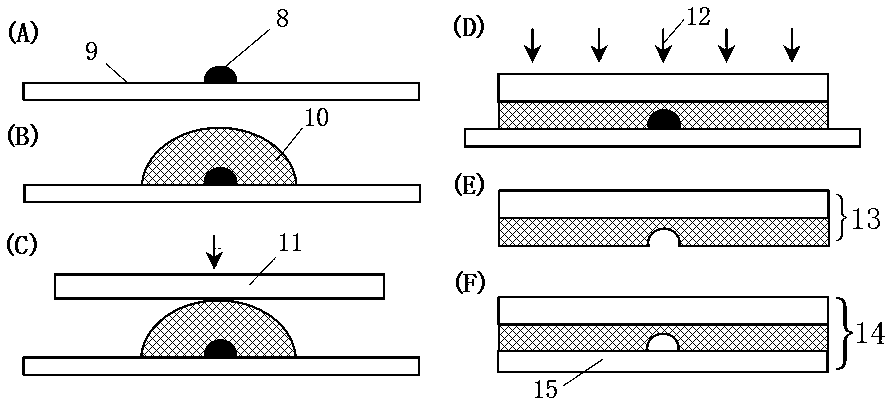

[0052] as attached figure 2 As shown, before printing the agar hydrogel positive mold, the polymethyl methacrylate bottom plate 9 is cleaned and then dried, coated with a small amount of release agent (0.5% sodium stearate solution) and dried, then placed in the 3D printer Fix and adjust the level on the printing platform at the bottom. Heat the agar thermally reversible hydrogel for 3D printing to 70°C to melt, inject i...

Embodiment 3、3

[0054] Example 3, Application of 3D printed carrageenan hydrogel positive mold in the preparation of epoxy resin microfluidic chip

[0055] The design and processing of the carrageenan hydrogel positive mold for casting epoxy resin microfluidic chips are the same as in Example 1. After mixing commercial E51 epoxy resin and curing agent ethylenediamine in a mass ratio of 90:10 and vacuum degassing, the epoxy resin casting solution containing curing agent can be obtained. Take 1.5 milliliters of the casting solution 10 along the carrageenan hydrogel anode. The center line of the long side of the mold 8 is poured on it, and covered with a self-made transparent epoxy resin cover plate 11 (75mm×16mm×1.0mm). The gap between the cover plate 11 and the hydrogel male mold 8 is 0.5 mm and filled with the casting solution 10 . For the epoxy resin casting solution cast between the hydrogel male mold 8 and the transparent epoxy resin cover plate 11, it is irradiated with infrared rays 12,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com