Positive pole material and lithium ion battery

A technology of positive electrode materials and positive active materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as complex processes, potential safety hazards, and harsh conditions, and achieve simple preparation processes, high safety, electronic conductivity and The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the positive electrode can adopt various methods commonly used in the art, such as using a solvent to prepare the positive electrode material provided by the invention into a positive electrode material slurry. The amount of solvent added is well known to those skilled in the art. Cloth viscosity and workability requirements are adjusted. Then the prepared positive electrode material slurry is drawn and coated on the positive electrode current collector (any positive electrode current collector known in the art can be used, such as aluminum foil), dried and pressed, and then cut into pieces to form the lithium ion battery positive electrode. The selection range of the drying temperature may be 90-150° C., and the drying time may be 10-40 minutes.

[0025] The solvent can be various solvents known in the art, preferably N-methylpyrrolidone (NMP), N,N-dimethylformamide (DMF), N,N-diethylformamide (DEF) One or more of , dimethyl sulfoxide (DMSO),...

Embodiment 1

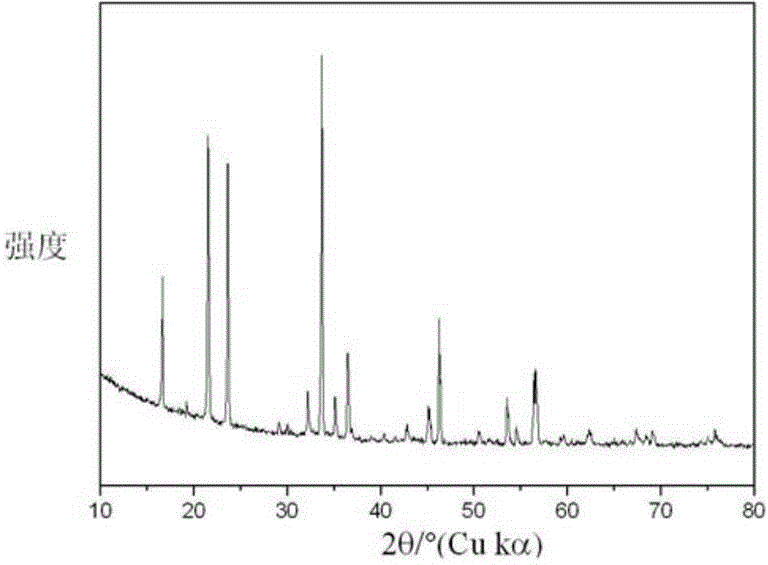

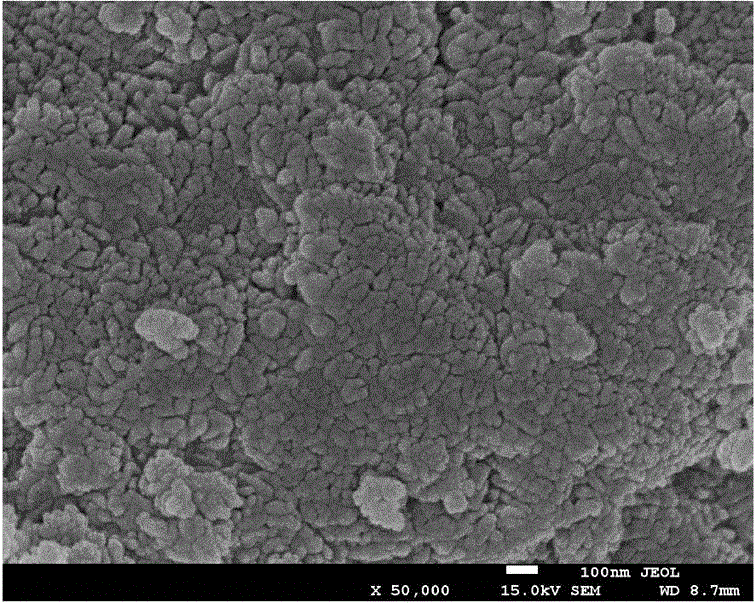

[0031] Will Li 2 O, Fe 2 o 3 and Al 2 o 3 Mix according to the molar ratio of 5:0.95:0.05, place in a stirring ball mill and mix and grind for 8 hours; the precursor prepared by fully mixing and grinding is pressed on a tablet machine, and then placed in a boron nitride box; put the box into In a tube furnace, nitrogen protection was introduced, and heating was started from room temperature at a heating rate of 5 °C / min. After heating to 850 °C, roasting for 48 hours, and then naturally cooling to room temperature, the additive S1 of this example was prepared, and its chemical formula was Li 5 Fe 0.95 Al 0.05 o 4 , its XRD spectrum is shown in figure 1 , SEM image see figure 2 .

Embodiment 2

[0033] Will Li 2 CO 3 , Fe 2 o 3 and Al(OH) 3 Mix according to the molar ratio of 5:0.9:0.2, place in a stirring ball mill for mixing and grinding for 6 hours; press the precursor prepared by fully mixing and grinding on a tablet machine, and then place it in a boron nitride box; put the box into In a tube furnace, nitrogen protection was introduced, and heating was started from room temperature at a heating rate of 5°C / min. After being heated to 800°C, it was roasted for 72 hours, and then naturally cooled to room temperature to obtain the additive S2 of this example, whose chemical formula was Li 5 Fe 0.9 Al 0.1 o 4 , its SEM image is shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com