Semi-high speed steel break-down (BD) roller and manufacturing method thereof

A semi-high-speed steel and manufacturing method technology, which is applied in the field of roll manufacturing, can solve the problems of low safety factor of roll use, inability to meet user needs, and poor quality of lower roll surface, so as to reduce procurement costs, improve rolling cycle and use. Safety and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with embodiment the present invention is described in further detail:

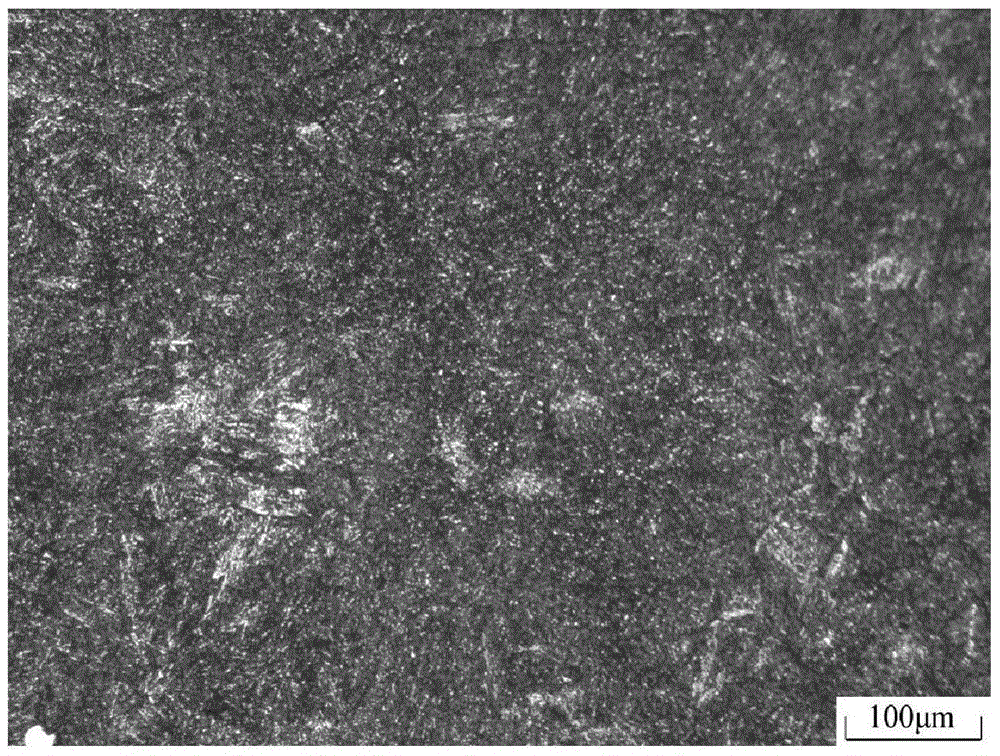

[0032] Such as figure 1 As shown, a semi-high-speed steel BD roller, the alloy components and weight percentages are C0.5%, Si0.45%, Mn0.7%, Cr5%, Ni0.5%, Mo0.9, W0.5 %, V0.2%, and the rest are iron and unavoidable impurities.

[0033] The manufacturing method of semi-high-speed steel BD roller comprises the steps:

[0034] A. Smelting raw materials: The semi-high-speed steel raw materials are smelted by electric arc furnace + refining outside the furnace, and the smelting temperature is 1500 ° C to obtain the material molten steel;

[0035] B. Integral pouring: transfer the molten steel melted in step A to the ladle, and pour the bottom pour into the mold at a pouring temperature of 1490°C;

[0036] C. After the roll is kept warm for 180 hours, it is demolded. After demoulding, the shape and size of the roll are roughly machined, and the entire roll is inspected for flaws; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com