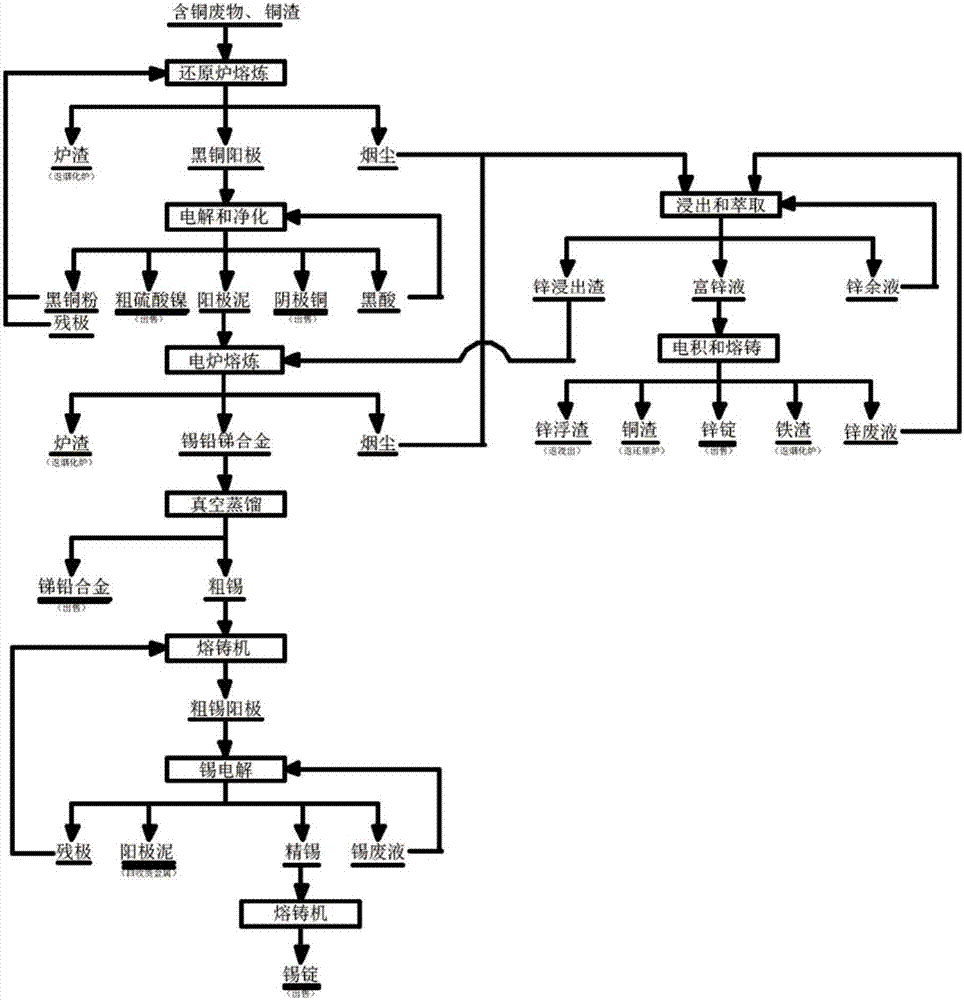

A multi-metal full-path full-valence separation method

A separation method and a full-path technology, applied in photography technology, equipment, photography auxiliary technology, etc., can solve the problems of large changes in gold and silver components, unsuitable extraction of valuable metals from copper-containing waste, complex sources of copper-containing waste, etc., to achieve The effect of many types of recovery, significant economy, and high metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1: Regenerative reduction furnace reduction smelting. The feeding ratio is: copper waste 65% (including copper slag brick 40%, copper powder ball 2%, copper-containing waste and residual pole 23%), flux 23% (including limestone 15%, quartz stone 8%), reducing agent 12% (coke or carbon). According to the operating system of the regenerative reduction furnace, the valuable metals in the materials are reduced and smelted, the air is blown to support the combustion, the flux and the oxides in the materials are slagged, and the valuable metals are reduced when the melt passes through the coke or carbon layer, and settle to the bottom of the furnace and the slag Separation to ensure that the slag contains less than 3% copper, nickel, lead, tin, etc., zinc and some metal vapors of lead and tin enter the flue with the flue gas, react with oxygen in the air, and enter the flue dust in the form of oxides. Release the copper liquid from the copper liquid outlet, and obtain a...

Embodiment 2

[0051] Step 1: Regenerative reduction furnace reduction smelting. The feeding ratio is: copper waste 75% (including copper slag brick 40%, copper powder ball 10%, copper-containing waste and residual pole 20%), flux 18% (including limestone 12%, quartz stone 6%), reducing agent 12% (coke or carbon). According to the operating system of the regenerative reduction furnace, the valuable metals in the materials are reduced and smelted, the air is blown to support the combustion, the flux and the oxides in the materials are slagged, and the valuable metals are reduced when the melt passes through the coke or carbon layer, and settle to the bottom of the furnace and the slag Separation to ensure that the slag contains less than 3% copper, nickel, lead, tin, etc., zinc and some metal vapors of lead and tin enter the flue with the flue gas, react with oxygen in the air, and enter the flue dust in the form of oxides. Release the copper liquid from the copper liquid outlet, and obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com