Recycling comprehensive utilization process of feldspars

A technology of recycling and feldspar, applied in the new technology field of comprehensive utilization of resources, can solve the problems of low added value of end products, discharge of residue and solid waste, etc., and achieve the effect of low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A resource comprehensive utilization process of feldspar, it comprises the following steps:

[0029] (1) Preparation of zeolite: Mix the ground feldspar and 6mol / L sodium hydroxide solution at a ratio of 1kg:20L, stir and react at 180°C for 16h, then filter and wash the obtained solid with deionized water The product is neutral, and then dried at 110°C to remove moisture to obtain silica-alumina zeolite;

[0030] (2) Acid treatment: Mix the silica-alumina zeolite obtained in step (1) with a 5mol / L HCl solution at a ratio of 1kg:20L, stir and react at 80°C for 6h, then filter and wash with deionized water to obtain The solid product was neutralized, and then dried at 110°C to remove moisture to obtain a mesoporous silica material prepared by a template-free method. The aluminum-containing acidic leaching solution obtained after filtration can be used to extract aluminum and prepare metallic aluminum or mesoporous alumina.

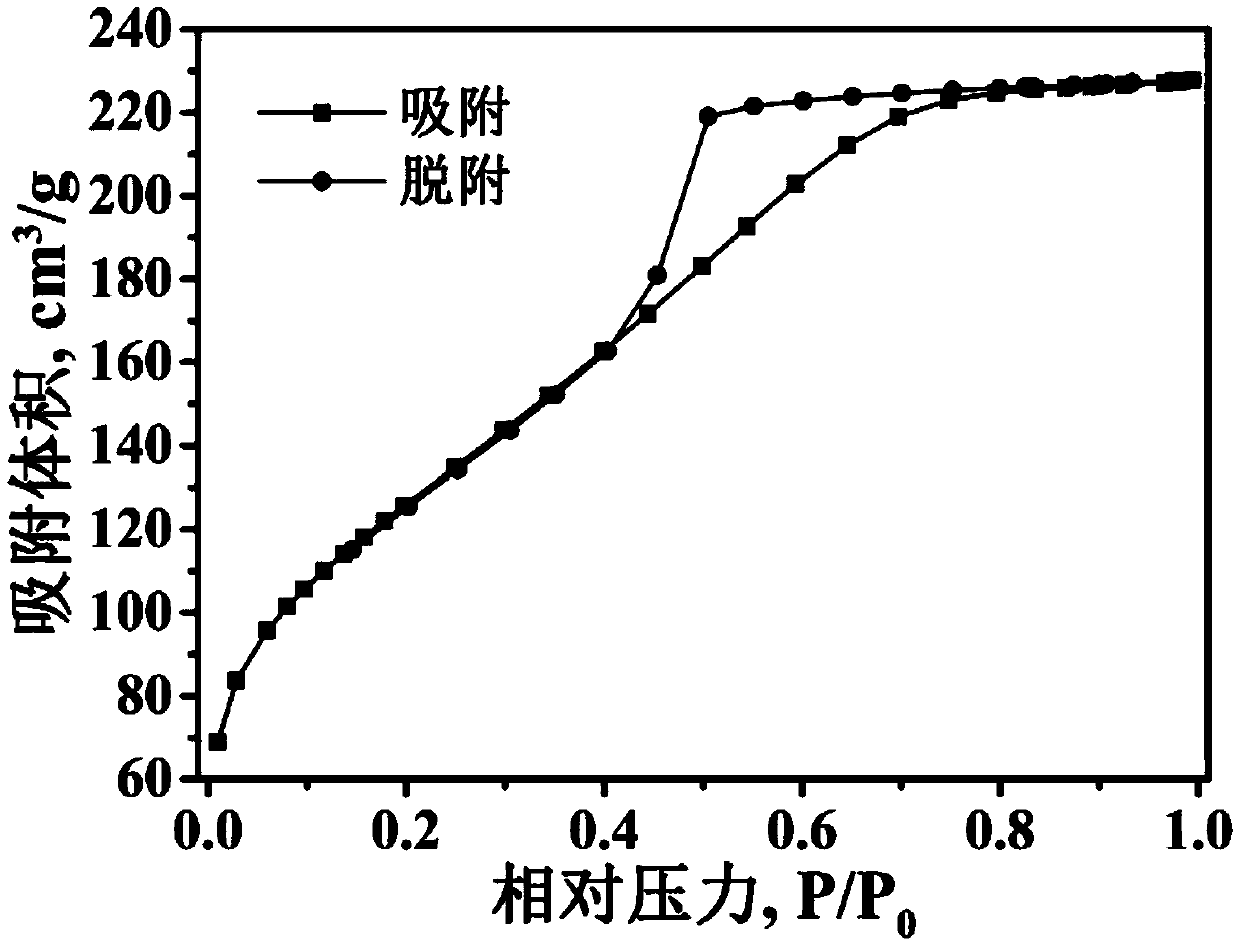

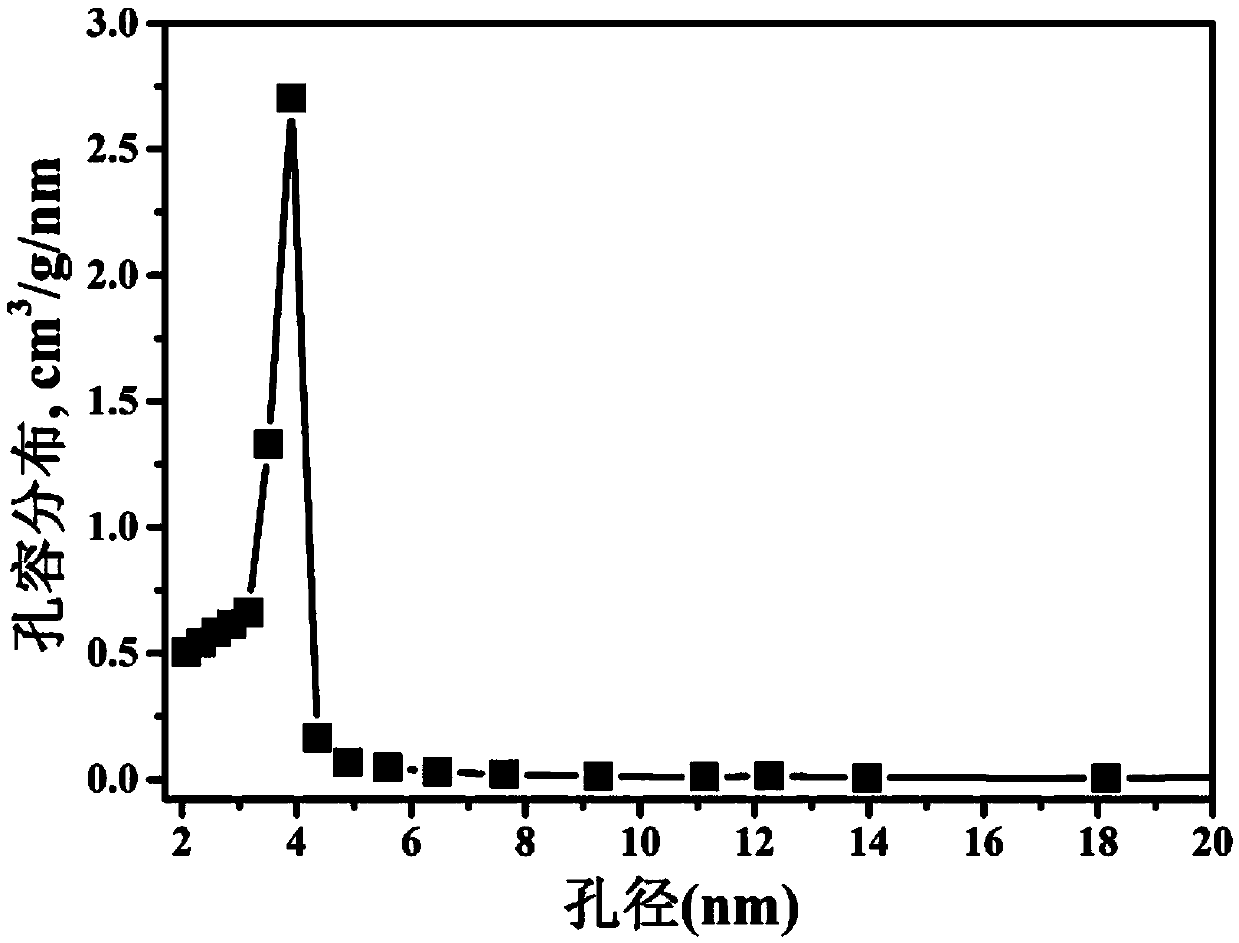

[0031] The specific surface area of the mes...

Embodiment 2

[0033] A resource comprehensive utilization process of feldspar, it comprises the following steps:

[0034] (1) Preparation of zeolite: Mix the ground potassium feldspar and 6mol / L sodium hydroxide solution in a ratio of 1kg:20L, stir and react for 16h at 180°C, and then filter to obtain the solid phase and potassium-containing alkaline solution. The obtained solid product was washed with deionized water to neutrality, and then dried at 110° C. to remove moisture to obtain a silica-alumina zeolite. The obtained potassium-containing alkali solution can be used to extract potassium;

[0035] (2) Acid treatment: Mix the silica-alumina zeolite obtained in step (1) with a 5mol / L HCl solution at a ratio of 1kg:20L, stir and react at 80°C for 6h, then filter and wash with deionized water to obtain The solid product was neutralized, and then dried at 110°C to remove moisture to obtain a mesoporous silica material prepared by a template-free method. Its aluminum-containing acidic le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com