Lubricant composition, preparation method thereof and trace amount of cutting fluid prepared through composition

A technology of lubricant composition and cutting fluid, applied in the field of lubrication, can solve problems such as lubrication and cooling problems that cannot be solved well, affecting the health of operators, processing places and environmental pollution, etc. Compression and abrasion resistance / good, water-soluble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Weigh 342.3g (1mol) of sucrose, 174.11g (1.5mol) of maleic acid, 258.39g (1.5mol) of n-decanoic acid, and 600g (3mol) of PEG200 into the reaction kettle, stir and heat to 190°C, and fully react for 12 hours , decompress and discharge water, which is a lubricant composition.

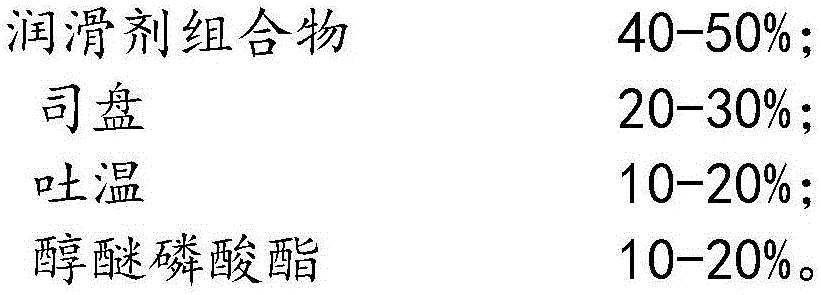

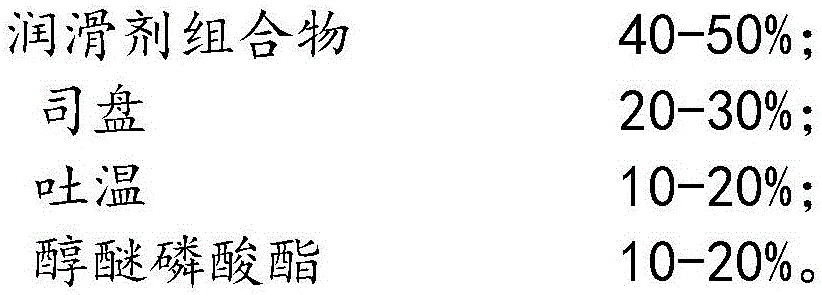

[0044] Weigh 500g of the above lubricant composition, 250g of SP-20, 150g of Tween-20, 100g of Rhodafac PA-24 alcohol ether phosphate, mix and stir at 60°C until it becomes transparent, then it becomes a kind of micro-cutting fluid.

[0045] The above micro-cutting fluid was subjected to four-ball extreme pressure test with GB / T12583 experimental method, and the test result: P D >620(kgf).

Embodiment 2

[0047] Weigh 342.3g (1mol) of sucrose, 118.09g (1mol) of succinic acid, 400.64g (2mol) of lauric acid, 600g (2mol) of PEG300, and 30g of dilute sulfuric acid (5%) into the reaction kettle, stir and heat to 260°C, After fully reacting for 6 hours, depressurizing and draining the water, it becomes a lubricant composition.

[0048] Weigh 400g of the above lubricant composition, 300g of SP-40, 160g of Tween-40, 140g of Rhodafac PA-26 alcohol ether phosphate, mix and stir at 60°C until it becomes transparent, then it becomes a kind of micro-cutting fluid.

Embodiment 3

[0050] Weigh 342.3g (1mol) of sucrose, 175.37g (1.2mol) of adipic acid, 256.42g (1mol) of palmitic acid, and 400g (1mol) of PEG400 into the reaction kettle, stir and heat to 240°C, fully react for 8 hours, reduce Press out the water, which is a lubricant composition.

[0051] Weigh 450g of the above lubricant composition, 250g of SP-60, 100g of Tween-60, 100g of Hostaphat 1322 alcohol ether phosphate, mix and stir at 60°C until it becomes transparent, then it becomes a micro cutting fluid. A micro cutting fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com