Water-based environment-friendly nano alloy floor paint and preparation method thereof

A nano-alloy and floor coating technology, which is applied in the direction of anti-corrosion coatings, fire-proof coatings, polyester coatings, etc., can solve the problem of poor acid resistance, solvent resistance, chemical resistance and stain resistance of the coating film, compactness and hardness of the coating film Poor, wear-resistant and poor service life, etc., to achieve good adhesion, full coating, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

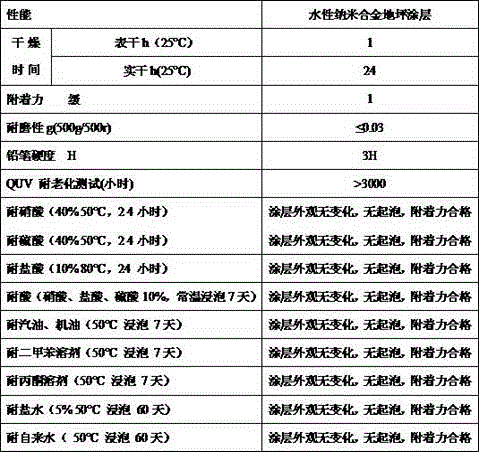

Examples

Embodiment 1

[0034] A kind of water-based environment-friendly nano-alloy floor coating, its preparation method comprises the following steps:

[0035] (1) Prepare raw materials according to the ratio shown in Table 1;

[0036] (2) Add all the deionized water, thickener, and 2 / 3 of the total amount of isopropanol into the dispersion kettle, and stir for 20 minutes at a speed of 450rpm to make the materials evenly mixed;

[0037] (3) Add all the nano-silica, nano-titanium powder, and water-soluble resin, and stir for another 30 minutes at a speed of 700rpm to mix the materials evenly;

[0038] (4) Add all the pigments, fillers, and 1 / 3 of the total amount of defoamer in sequence, and stir at 600rpm for 1.5 hours to obtain component A;

[0039] (5) Add all the active siloxane and wetting agent, and the rest of isopropanol and defoamer to another dispersing kettle, and stir at 450rpm for 50 minutes to mix the materials evenly to obtain component B;

[0040] (6) Mix the obtained component A ...

Embodiment 2

[0046] A kind of water-based environment-friendly nano-alloy floor coating, its preparation method comprises the following steps:

[0047] (1) Prepare raw materials according to the ratio shown in Table 3;

[0048] (2) Add all the deionized water, thickener, and 2 / 3 of the total amount of isopropanol into the dispersion kettle, and stir for 30 minutes at a speed of 400rpm to make the materials evenly mixed;

[0049] (3) Add all the nano-silica, nano-titanium powder, and water-soluble resin, and stir for another 30 minutes at a speed of 600 rpm to mix the materials evenly;

[0050] (4) Add all the pigments, fillers, and 1 / 3 of the total amount of defoamer in sequence, and stir at 500rpm for 2 hours to obtain component A;

[0051] (5) Add all the active siloxane and wetting agent, and the rest of isopropanol and defoamer to another dispersing kettle, and stir at 450rpm for 50 minutes to mix the materials evenly to obtain component B;

[0052] (6) Mix the obtained component A and...

Embodiment 3

[0058] A kind of water-based environment-friendly nano-alloy floor coating, its preparation method comprises the following steps:

[0059] (1) Prepare raw materials according to the ratio shown in Table 5;

[0060] (2) Add all the deionized water, thickener, and 1 / 3 of the total amount of isopropanol into the dispersion kettle, and stir for 30 minutes at a speed of 400rpm to make the materials evenly mixed;

[0061] (3) Add all the nano-silica, nano-titanium powder, and water-soluble resin, and stir for another 30 minutes at a speed of 600 rpm to mix the materials evenly;

[0062] (4) Add all the pigments, fillers, and 2 / 3 of the total amount of defoamer in sequence, and stir at 500rpm for 2 hours to obtain component A;

[0063] (5) Add all the active siloxane and wetting agent, and the rest of isopropanol and defoamer to another dispersing kettle, and stir at 450rpm for 50 minutes to mix the materials evenly to obtain component B;

[0064] (6) Mix the obtained component A a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com