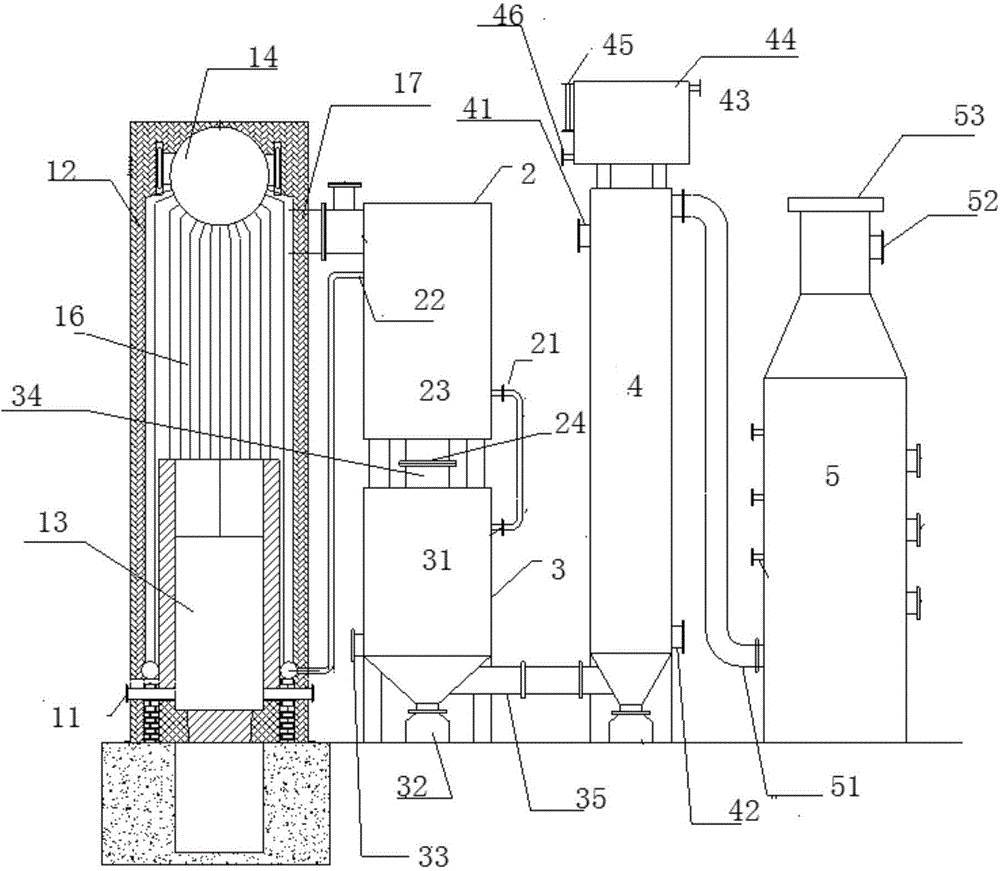

Clean and efficient biomass micron fuel high-temperature industrial boiler

A high-temperature industry and biomass technology, applied in steam boilers, fuel supply, water-tube steam boilers, etc., can solve the problems of low combustion rate, not recommended to use, low temperature, etc., and achieve the effect of increasing combustion temperature and accelerating combustion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

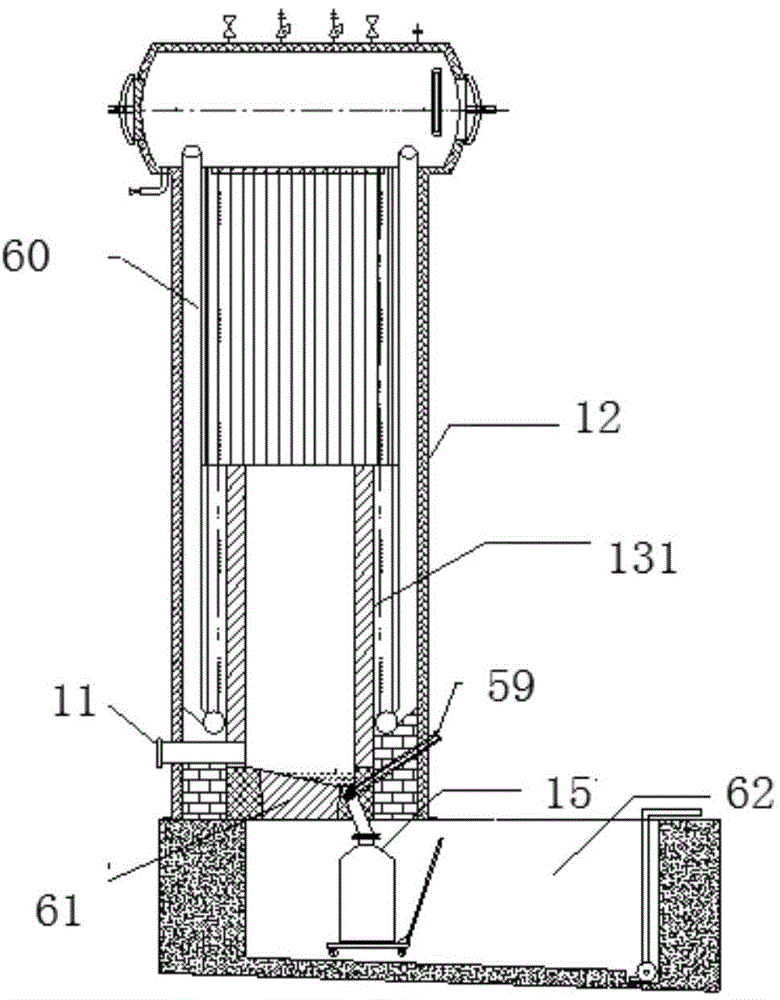

Embodiment 1

[0045] The feed rate of biomass micron fuel is 700kg / h, the calorific value of fuel is 4100Kcal / kg, the diameter of the adiabatic combustion chamber is 1400mm, and the height is 1800mm. into the oven cavity. The furnace cavity is lined with refractory bricks, the thickness of the lining is 114mm, and the outside of the lining bricks is insulated with a certain thickness of high-purity alumina fiber cotton.

[0046] The following are the combustion temperature test results under the combustion conditions of different thicknesses of inner lining and outer heat-resistant insulation cotton and different excess air coefficients:

[0047]

[0048] Table 1

Embodiment 2

[0050]The feed amount of biomass micron fuel is 705kg / h, and the calorific value of fuel is 4100Kcal / kg. The diameter of the adiabatic combustion chamber is 1400mm. After the micron fuel is evenly mixed with the excess air of 1.05, it is sent into the furnace chamber tangentially from the bottom at a wind speed of 5 m / s. The furnace cavity is lined with refractory bricks, the thickness of the lining is 114mm, and the outside of the lining bricks is kept insulated with 150mm thick high-purity alumina fiber cotton. The combustion temperature test results under different adiabatic combustor heights can be found in Table 2 below, and the smoke blackness test results under different adiabatic combustor temperatures and water vapor conditions can be seen in Table 3 below.

[0051]

[0052] Table 2

[0053]

[0054] table 3

[0055] Therefore, according to the situation that the combustion temperature of the present invention is increased by an average of 150 degrees compared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com