Preparation method of double-self-cleaning fabric with lasting and good photocatalytic self-cleaning and surface super-hydrophobic effects

A self-cleaning and fabric technology, applied in the field of preparation of dual self-cleaning fabrics, can solve the problems of low self-cleaning durability, no catalytic effect, catalytic efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention provides a method for preparing dual self-cleaning fabrics, which includes the following steps:

[0044] Step 1: Add modified nano titanium dioxide to water;

[0045] Step 2: Irradiate the fabric;

[0046] Step 3: Immerse the fabric treated in step 2 in the modified nano-titanium dioxide aqueous solution prepared in step 1, and optionally dry after taking it out to obtain a self-cleaning fabric.

[0047] In a preferred embodiment, in step 1, the modification methods of the modified nano-titanium dioxide include metal and non-metal doping, semiconductor composite, surface precious metal precipitation, dye sensitization and conjugated polymer doping modification. Sex.

[0048] In a further preferred embodiment, in step 1, the modification mode of the modified nano titanium dioxide is conjugated polymer doping modification, for example: polythiophene, polyaniline, polypyrrole or polyvinyl alcohol PVA doping .

[0049] In a further preferred embodiment, in step...

Embodiment 1

[0102] Example 1 Preparation of modified nano titanium dioxide

[0103] Add 2g of nano titanium dioxide into a three-necked flask containing 50mL of deionized water, then add 4g of polyethylene glycol PEG, mechanically stir for 3h, add 2% polyvinyl alcohol PVA aqueous solution, continue to mechanically stir for 2h, add 20mL methanol, Stop stirring.

[0104] The sample was filtered and washed clean, placed in a muffle furnace and calcined at 180°C for 2 hours to obtain modified nano titanium dioxide, which was recorded as M-TiO 2 .

Embodiment 2

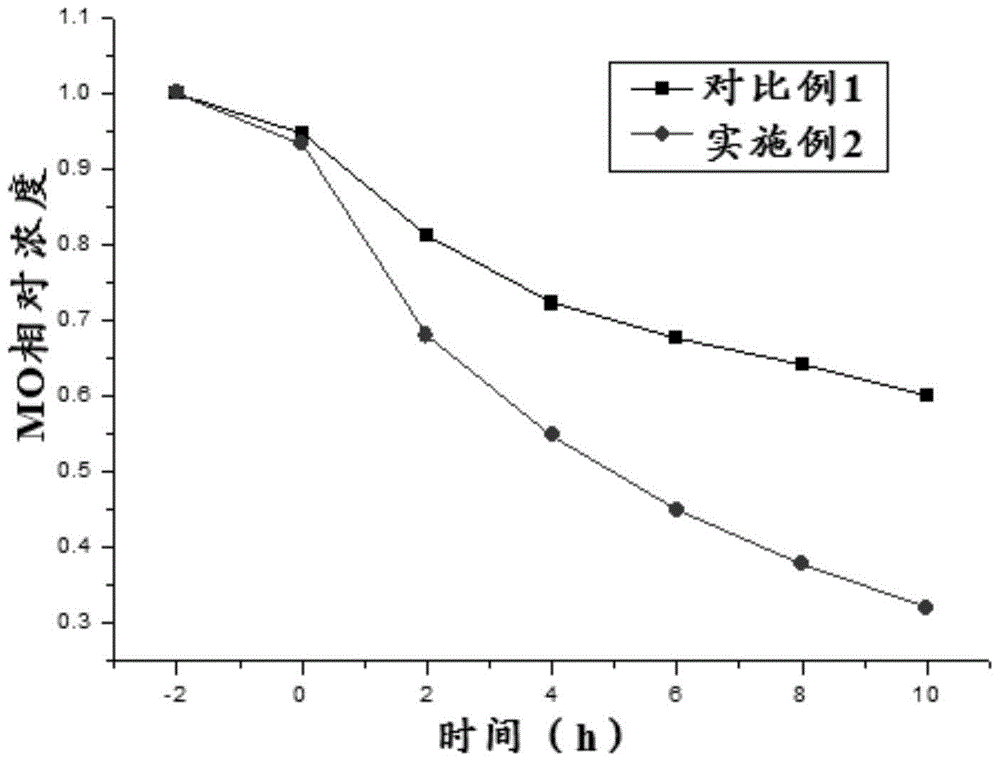

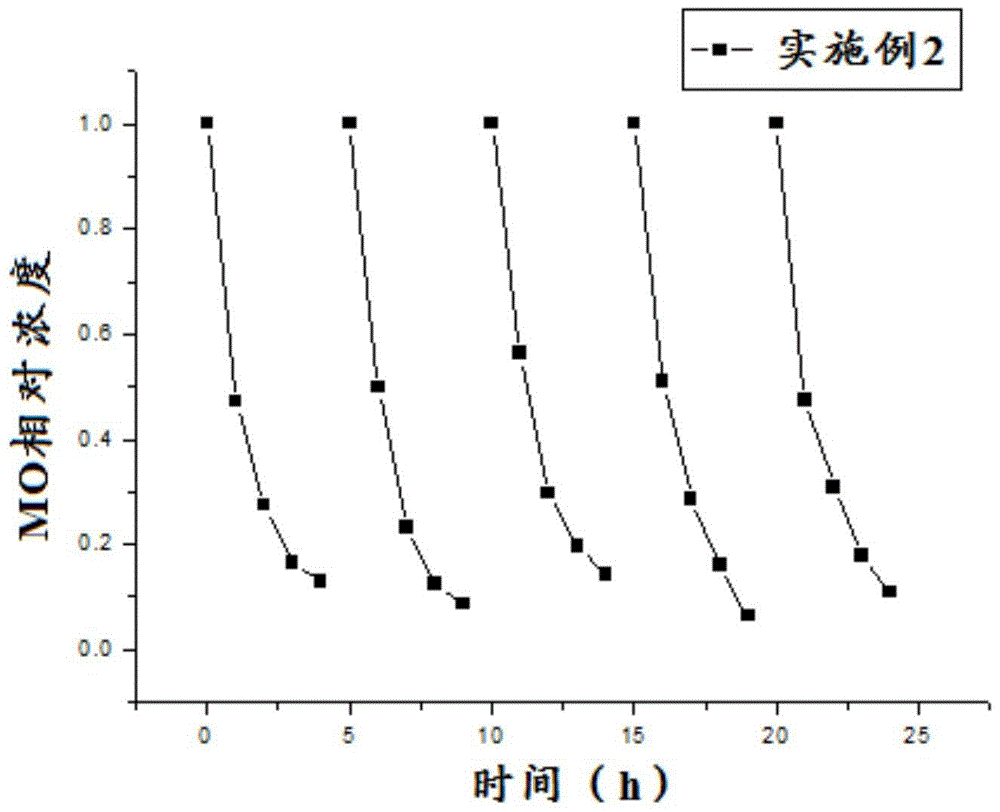

[0105] Example 2 Preparation of double self-cleaning fabric

[0106] (1) Add 1g of the modified nano-titanium dioxide prepared in Example 1 to 100mL of deionized water, and ultrasonic;

[0107] (2) Irradiate the desizing nylon fabric under normal pressure with ultraviolet for 30 minutes;

[0108] (3) Immerse the nylon fabric treated in (2) in the nano-titanium dioxide aqueous solution in (1), ultrasonicate for 30 minutes, take it out in a blast oven and bake for 10 minutes at 60°C, and then immerse again in the nano-titanium dioxide aqueous solution in (1) In the medium, ultrasonic for 30 minutes, take it out and bake it in a blast oven at 60°C for 10 minutes;

[0109] (4) Transfer the dried nylon fabric to a vacuum oven, vacuum and dry at 140°C for 120 minutes, to obtain a fabric with long-lasting and good photocatalytic self-cleaning effect, denoted as M-TiO 2 -PA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com