Noctilucent organic composite coating and preparation method thereof

A composite coating, organic technology, applied in the field of coatings, can solve the problems of uneven dispersion of luminous powder, poor compatibility, reduced mechanical properties of coatings, etc., to improve compatibility and interface bonding strength, improve luminous performance, and improve luminous effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

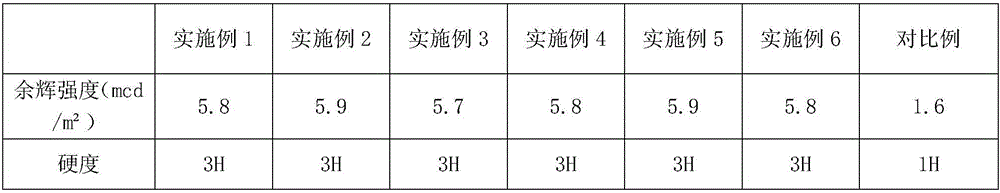

Examples

Embodiment 1

[0033] Luminous organic composite paint, including the following components by weight: 36 parts of cross-linked FEVE fluororesin, 10 parts of epoxy acrylate, 5 parts of polyether type unsaturated polyurethane resin, 0.2 parts of dimethylsiloxane leveling agent 12 parts of ethyl acetate, 1 part of polyacrylate dispersant, 8.5 parts of aluminum powder, 11 parts of quartz powder, 11 parts of modified luminous powder, 0.8 parts of organic bentonite, and 5.5 parts of hollow glass microspheres.

[0034] The preparation method of the luminous organic composite coating is:

[0035] (1) Zirconium oxychloride is added in dehydrated alcohol, after stirring evenly, add bayberry tannin, after stirring for 45 minutes, adjust the pH value to 4, continue to stir for 6 hours and age for 2 hours to obtain zirconium solution, wherein Zr, anhydrous The molar ratio of ethanol and bayberry tannin is 1:50:1; strontium sulfate, aluminum sulfate, europium nitrate, and yttrium chloride are added dropwi...

Embodiment 2

[0039] Luminous organic composite paint, including the following components by weight: 34 parts of cross-linked FEVE fluorine resin, 12 parts of epoxy acrylate, 10 parts of polyether type unsaturated polyurethane resin, 0.1 parts of dimethylsiloxane leveling agent 14 parts of ethyl acetate, 0.8 parts of polyacrylate dispersant, 8.8 parts of aluminum powder, 13 parts of quartz powder, 13 parts of modified luminous powder, 0.6 parts of organic bentonite, and 7 parts of hollow glass microspheres.

[0040] Its preparation method is with embodiment 1.

Embodiment 3

[0042] Luminous organic composite paint, including the following components by weight: 35 parts of cross-linked FEVE fluororesin, 14 parts of epoxy acrylate, 8 parts of polyether type unsaturated polyurethane resin, 0.1 parts of dimethylsiloxane leveling agent 16 parts of ethyl acetate, 0.7 parts of polyacrylate dispersant, 9.5 parts of aluminum powder, 12 parts of quartz powder, 15 parts of modified luminous powder, 0.4 parts of organic bentonite, and 6.5 parts of hollow glass microspheres.

[0043] Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com