Complete equipment for further separating methanol and water from C4

A complete set of equipment and methanol removal technology, which is applied in the field of microphase separation, can solve problems such as insufficient separation precision, increased water content, waste of water resources, etc., and achieve the effects of reducing water consumption, fast processing speed, and reducing device operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

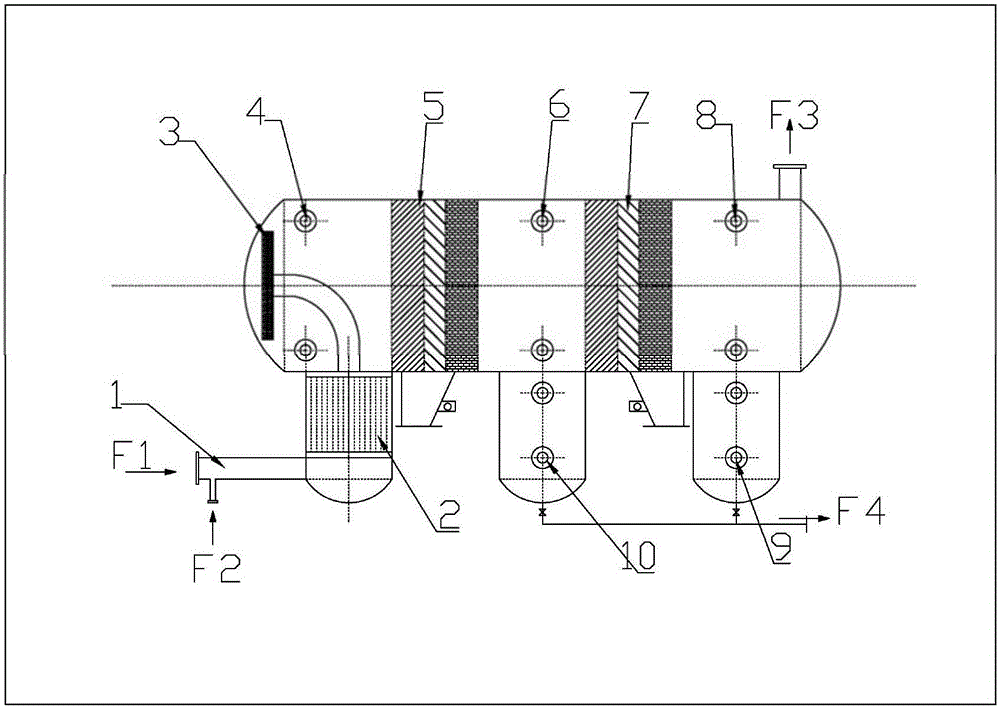

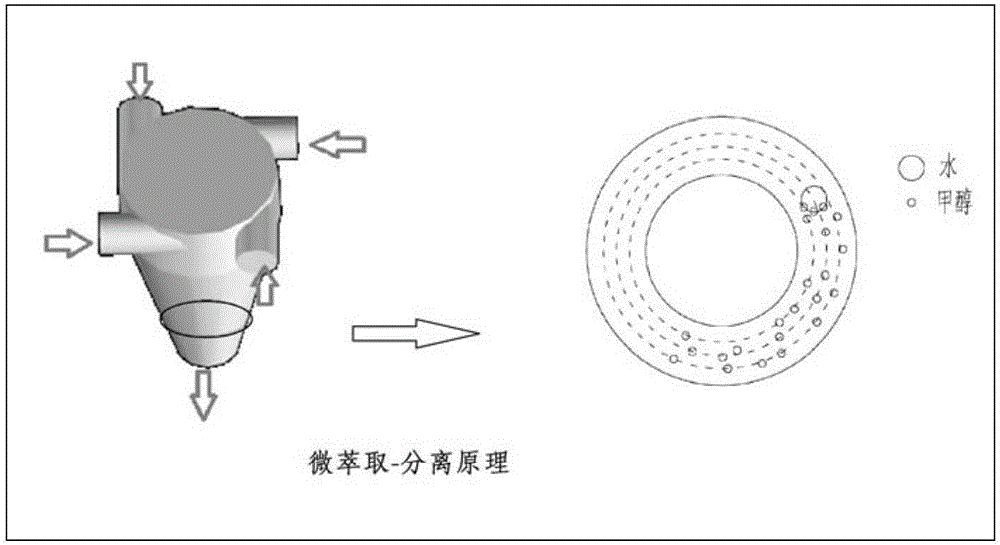

[0038] figure 1 It is a schematic structural diagram of the complete set of equipment in this embodiment. As shown in the figure, according to the fluid flow direction, the C4 raw material F1 and desalted water F2 enter the microphase disperser 1, and are broken into tiny droplets under the action of the shear flow field , the particle size distribution range is 10-15 μm, small droplets such as C4, methanol, and water are fully mixed and evenly distributed inside the pipeline of the micro-phase disperser 1; the mixed liquid enters the parallel micro-swirl flow extraction tube group 2 , using the variable diameter structure of the micro-swirl tube, the mixed liquid is fully extracted under the action of the centrifugal field, and the fully extracted mixed liquid enters the fluid distributor 3, and then evenly enters the first-stage coalescence separator 5 to achieve preliminary separation Enter into the secondary coalescing separator 7 again to realize deep separation of methan...

Embodiment 2

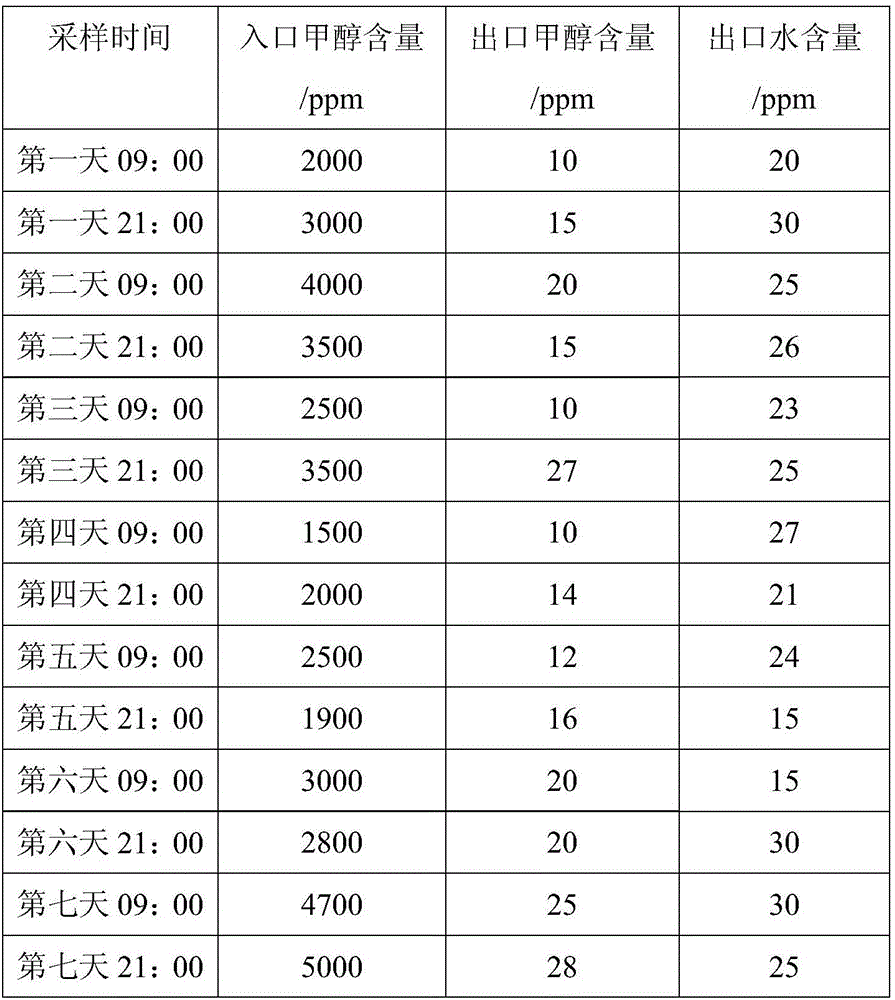

[0040] In a local refining company in Shandong, the C4 raw material in the water washing tower of the alkylation workshop contained 1,000-5,000 ppm of methanol, and the imported methanol content fluctuated widely. The consumption and amount of waste acid remain high. In response to this situation, 26 micro-swirl extraction tubes connected in parallel and secondary separation devices connected in series are used to replace the original water washing tower in the alkylation workshop, with a processing capacity of 30t / h and a temperature of 30 ~40°C, the water intake is 5%, the pressure drop of the equipment is not more than 0.06Mpa, the technical requirements are not more than 5000ppm at the inlet, and not more than 30ppm at the outlet. Table 1 shows the analysis of sampling data for equipment start-up calibration.

[0041] Table 1

[0042]

[0043] The identification results show that the original water washing tower in the alkylation workshop can be replaced by connecting ...

Embodiment 3

[0045] In a refinery company in Shandong, the C4 raw material in the water washing tower of the etherification workshop contained 40,000-50,000 ppm of methanol. The amount of acid remains high. In response to this situation, 12 micro-swirl extraction tubes connected in parallel and three-stage separation devices connected in series are used to replace the original water washing tower in the alkylation workshop. The processing capacity is 10t / h, and the temperature is 30-40°C. The water intake is 8%, the pressure drop of the equipment does not exceed 0.06Mpa, the technology requires that the gas inlet is not more than 50000ppm, and the outlet is not more than 30ppm. Table 2 shows the analysis of sampling data for equipment start-up calibration.

[0046] Table 2

[0047]

[0048] The identification results show that the parallel connection of 12 micro-swirl extraction tubes and the series connection of the three-stage separation device can replace the original water washing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com