Polyimide superfine fiber and preparation method thereof

A polyimide fiber and ultrafine fiber technology, applied in the chemical characteristics of fibers, spinning solution preparation, wet spinning and other directions, can solve the problem of no polyimide ultrafine fibers, etc. The effect of regular chain arrangement and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

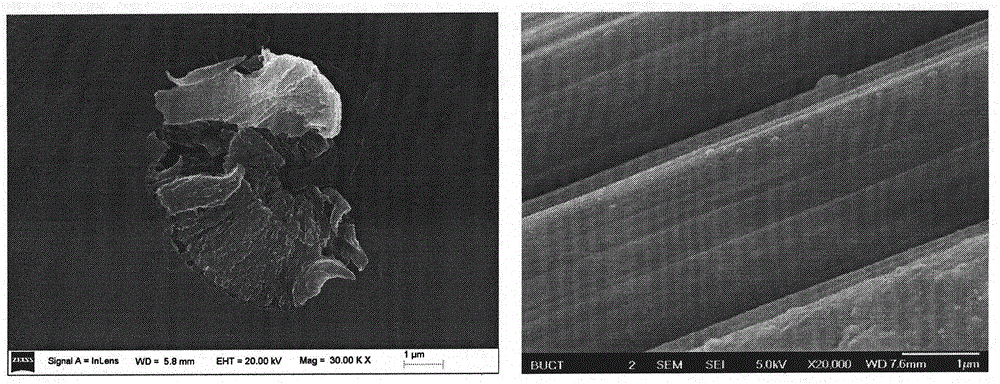

Image

Examples

Embodiment 1

[0027] Synthesis of polyamic acid solution: according to the molar ratio of PMDA:ODA=1:1, first place ODA diamine monomer in a three-necked flask, add a measured amount of solvent (DMAc), and stir under nitrogen protection to completely dissolve ODA , then add PMDA in batches and stir to make the solid content 9%, and then stir at 0-30°C for 12 hours under the protection of nitrogen to obtain a viscous polyamic acid solution with an intrinsic viscosity of 1.5dL / g.

[0028] Preparation of polyamic acid fiber: The polyamic acid solution is defoamed, and the wet process is used for spinning, the spray ratio is 6, the spinneret is 1000×Φ0.04mm, and the coagulation bath is pure water.

[0029] Thermal imidization of polyamic acid fibers: polyimide fibers are cyclized at high temperatures in stages to obtain polyimide ultrafine fibers.

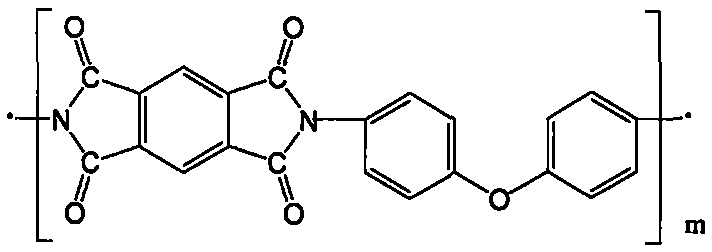

[0030] The structural formula of the obtained fiber is as follows:

[0031]

[0032] The monofilament linear density is 0.153dtex, the tensile ...

Embodiment 2

[0035] Synthesis of polyamic acid solution: according to the molar ratio of PMDA: ODA: p-PDA = 10: 3: 7, first place ODA and p-PDA diamine monomers in a three-necked flask, and add a measured amount of solvent (DMAc) , stirred under the protection of nitrogen to completely dissolve ODA and p-PDA, then added PMDA in batches and stirred to make the solid content 10%, and then stirred at 0-20°C for 8 hours under the protection of nitrogen to obtain a viscous polyamide The acid solution has an intrinsic viscosity of 1.53dL / g.

[0036] Preparation of polyamic acid fiber: polyamic acid solution is defoamed and spun by wet process, the spray ratio is 5, the spinneret is 800×Φ0.04mm, and the coagulation bath is a mixture of water and DMAc.

[0037] Thermal imidization of polyamic acid fibers: Cyclization of polyimide fibers at high temperatures.

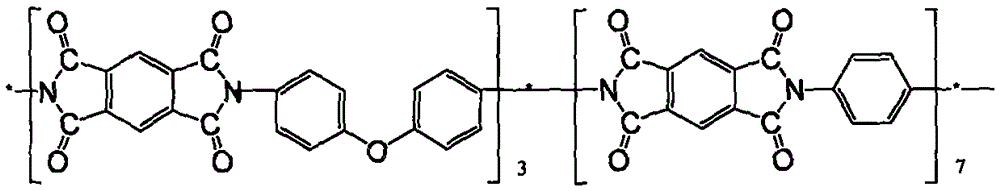

[0038] The structural formula of the resulting fiber:

[0039]

[0040] The monofilament linear density is 0.205dtex, the tensile stre...

Embodiment 3

[0042]Synthesis of polyamic acid solution: according to the molar ratio of BPDA: ODA: p-PDA = 10: 5: 5, first place ODA and p-PDA diamine monomers in a three-necked flask, and add a measured amount of solvent (DMAc) , stirred under the protection of nitrogen to completely dissolve ODA and p-PDA, then added BPDA in batches and stirred to make the solid content 11%, and then stirred at 0-50°C for 10 hours under the protection of nitrogen to obtain viscous polyamide The acid solution has an intrinsic viscosity of 1.6dL / g.

[0043] Preparation of polyamic acid fiber: polyamic acid solution is defoamed and spun by dry-wet process. The spray ratio is 4, the spinneret is 500×Φ0.06mm, the coagulation bath is pure water, and the length of the air layer is It is 1cm.

[0044] Thermal imidization of polyamic acid fibers: Cyclization of polyimide fibers at high temperatures.

[0045] The structural formula of the resulting fiber:

[0046]

[0047] The bundle linear density is 0.245d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com