Ocean observation float mooring system and mixed cable for same

A cable and buoy technology, applied in the field of fiber ropes, can solve the problems affecting the use of the mooring system, heavy weight, large storage radius, etc., and achieves good promotion and application prospects, high breaking strength, and easy deployment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

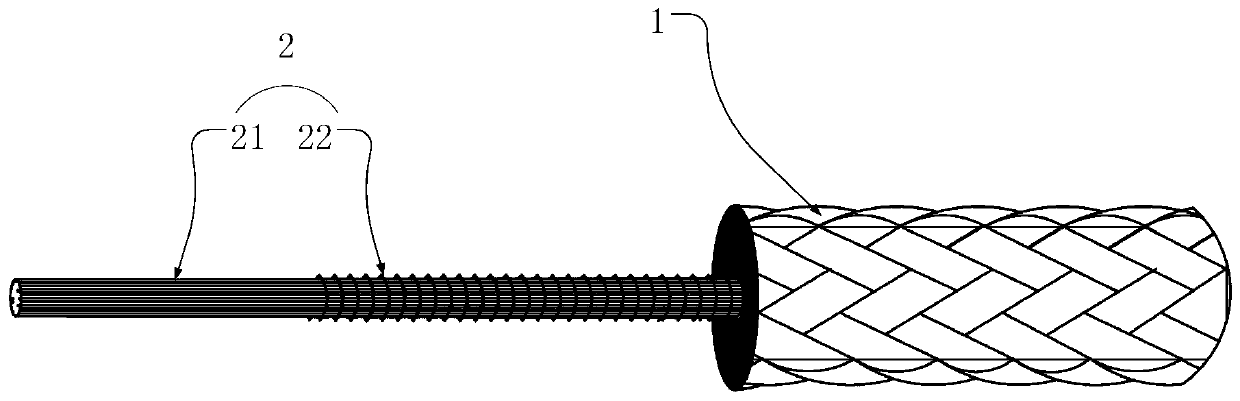

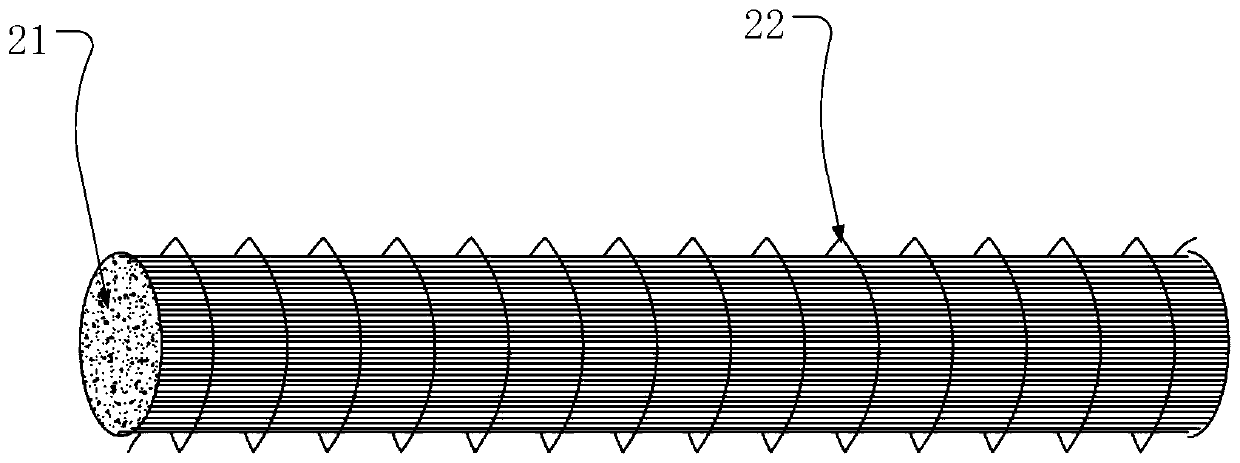

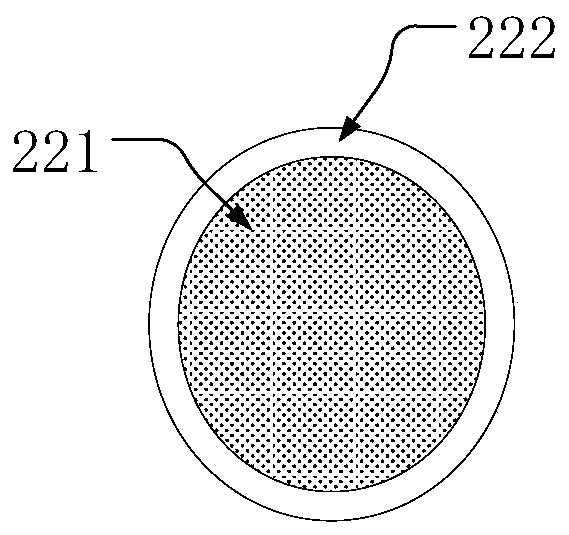

[0059] figure 1 It is a schematic diagram of the structure of the hybrid cable used for the ocean observation buoy mooring system disclosed in Embodiment 1, figure 2 It is a schematic diagram of the structure of the metal fiber hybrid rope core in the hybrid cable, image 3 Schematic diagram of the cross-section of a cylindrical plastic-coated wire for making a metal helical spring, Figure 4 Schematic diagram of the cross-section of the hybrid cable.

[0060] figure 1 Among them, the fiber support core 21 is arranged inside the metal coil spring 22, the fiber support core 21 and the metal coil spring 22 form a metal fiber mixed rope core 2, and the metal fiber mixed rope core 2 is woven with a rope sheath 1.

[0061] figure 2 Among them, the rope core fibers are bundled into one strand to form a cylindrical fiber support core 21, the fiber support core 21 is wrapped with plastic-coated wire, and the wrapped plastic-coated wire forms a metal coil spring 22, and the diame...

Embodiment 2

[0065] The hybrid cable for the observation buoy mooring system disclosed in embodiment 2 is prepared through the following steps:

[0066] 1260D polyamide 6 fiber multifilament is used as raw material, the breaking strength of the fiber multifilament is ≥8.5cN / dtex, and the elongation at break is equal to 22%;

[0067] Five 1260D polyamide 6 fiber multifilaments are used to form one yarn, and the initial twist is performed during the doubling process, with a twist of 110 twists / m, and then the three yarns are combined into one rope yarn, and the double twist is performed during the doubling process , the twist is 100 twists / meter, and the twist direction of primary twist and double twist is all divided into S twist direction and Z twist direction, and S twist direction rope yarn and Z twist direction rope yarn are obtained respectively;

[0068] Combine 8 rope yarns into 1 strand, and the structure is 7 strands around the middle one, that is, 7+1 structure. Twist is added dur...

Embodiment 3

[0074] The hybrid cable for the observation buoy mooring system disclosed in embodiment 3 is prepared through the following steps:

[0075] 2000D polyester fiber multifilament is used as raw material, the breaking strength of the fiber multifilament is ≥8cN / dtex, and the elongation at break is equal to 12%;

[0076] Six 2000D polyester fiber multifilaments are combined into one yarn, and the initial twist is carried out during the doubling process, with a twist of 90 twists / m. Then the three yarns are combined into one rope yarn, and the double twisting is performed during the doubling process. The twist degree is 80 twists / meter, and the twist direction of primary twist and double twist is divided into S twist direction and Z twist direction, and S twist direction rope yarn and Z twist direction rope yarn are obtained respectively;

[0077] 15 rope yarns are combined into 1 rope strand, twisted during the yarn combination process, and the twist is 60 twists / meter, and the rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com