Production equipment and production method of steel cords

A technology of production equipment and production method, which is applied to auxiliary devices for rope making, textiles and papermaking, textile cables, etc., can solve the problems of increasing equipment investment, uneconomical, increasing personnel, and turnover costs of semi-finished products, and achieves a reduction in floor space , Improve production efficiency, the effect of impact resistance advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

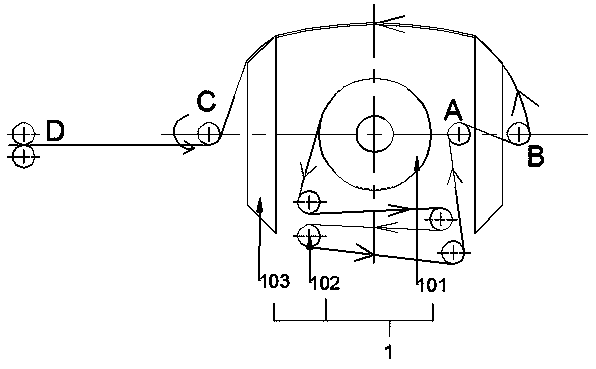

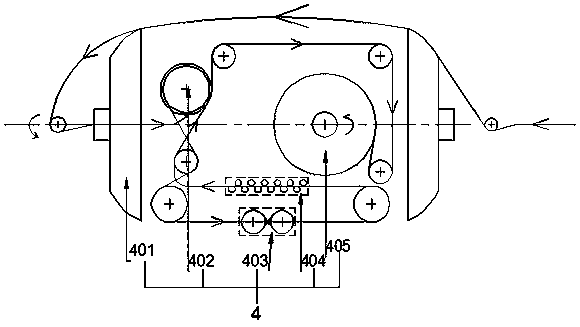

[0047] The steel wires of the same diameter drawn by 2-3 wet drawing machines are collected on a pay-off I-shaped wheel 101 according to the same drawing speed, so as to ensure that the 2-3 steel wires taken up at the same time are arranged evenly and the take-up The tension is the same, and the I-shaped wheels are unloaded according to the corresponding fixed length; then according to the number of strands of the finished cord, the corresponding number of I-shaped wheels are respectively placed in each prefabricated device 1, and passed through according to the corresponding winding method. Tension adjustment device 102, pre-twisting auxiliary flywheel disc 103, over-twisting device 2; multi-strand yarns are evenly distributed on the thread distribution disc 301, and then meet at the thread gathering nozzle 302, and the thread gathering nozzle 302 is selected according to the specifications of the finished cord And the die 303, the multi-strand wires gathered together enter th...

Embodiment

[0049] Existing product 4×2×0.25HE production

[0050] Put two rounds of heat-treated electroplated brass steel wire with a diameter of 1.48 on two wet drawing machines respectively, and then complete the mold penetration according to the wet drawing process of 1.48-0.25, and pass the steel wire drawn by one of the wet drawing machines through the wire passing wheel And go to the traction wheel of the other wet drawing machine to link the electric control parts of the two wet drawing machines so that the drawing speeds of the two wet drawing machines are consistent, and the combined two steel wires are collected in one pay-off worker 4 such pay-off I-shaped wheels 101 are respectively placed on the I-shaped wheel placement device in the prefabricated device 1, and the steel wire presses figure 1 In the threading method shown, it goes through the pre-twisting secondary flywheel disc 103, the over-twisting assembly 203, to the line distribution disc 301, and then passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com