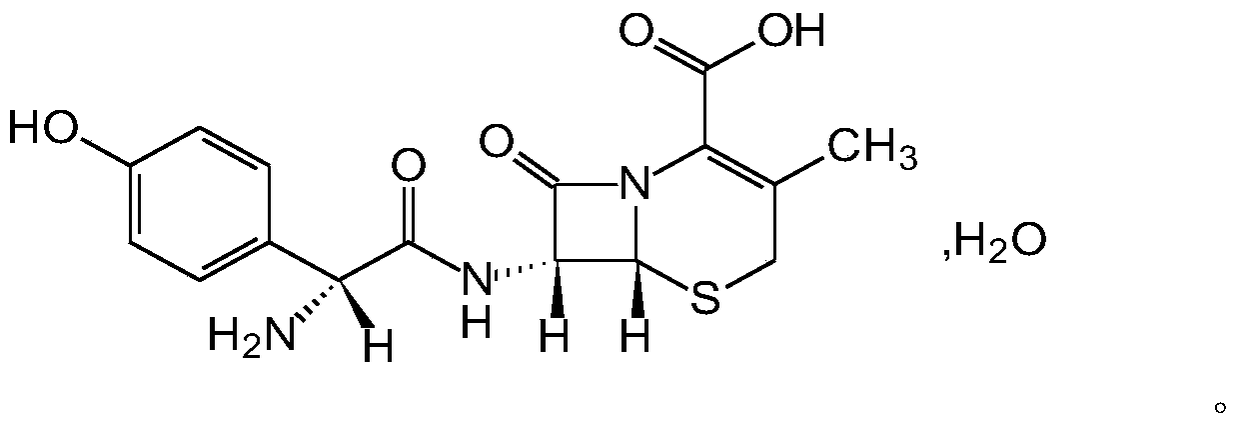

A kind of cefadroxil granule preparation and preparation method thereof

A technology of cefadroxil granules and fadroxil granules, applied in the field of medicine, can solve problems such as easy hygroscopic degradation, hidden safety hazards, unfavorable long-term storage, etc., and achieve the effects of improved bioavailability and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 cefadroxil of the present invention

[0032] (1) 100 g of cefadroxil crude product is dissolved in 800 ml of mixed solvent A of tetrahydrofuran and water with a volume ratio of 1:2, and ammonia water is added dropwise to adjust the pH value to 8.0;

[0033] (2) Filter, add dropwise acetic acid to the filtrate to adjust the pH value to 6.8, then slowly add 320ml dropwise of a mixed solvent B of 2-butanone and chloroform with a volume ratio of 1:0.3, stir while adding, and the stirring speed is 20 rpm / Minute;

[0034] (3) Cool down to 5°C, crystallize, and grow crystals for 4 hours;

[0035] (4) Filtrate to obtain a solid, and dry it under reduced pressure at 35° C. for 3 hours to obtain 97.92 g of cefadroxil.

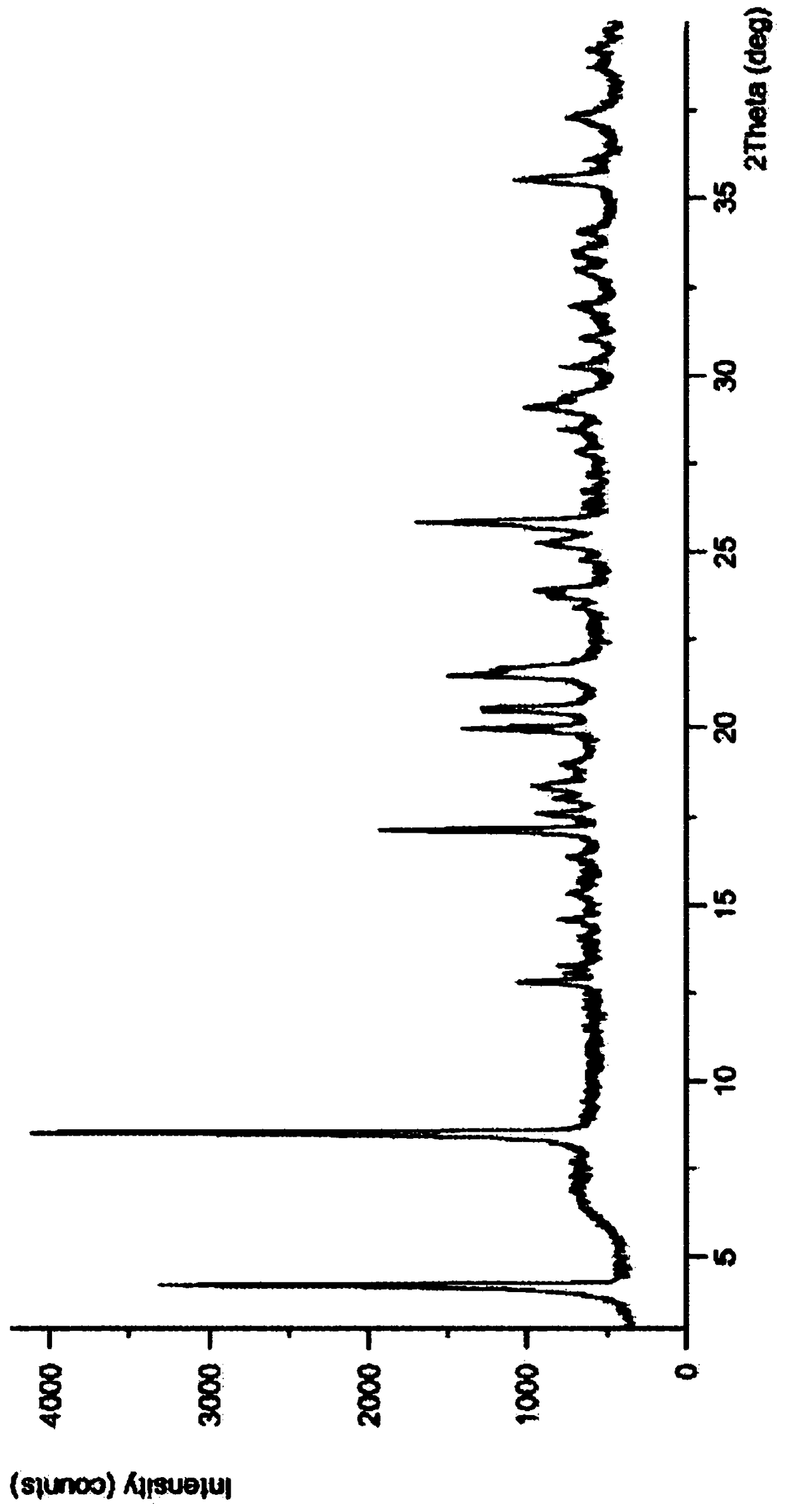

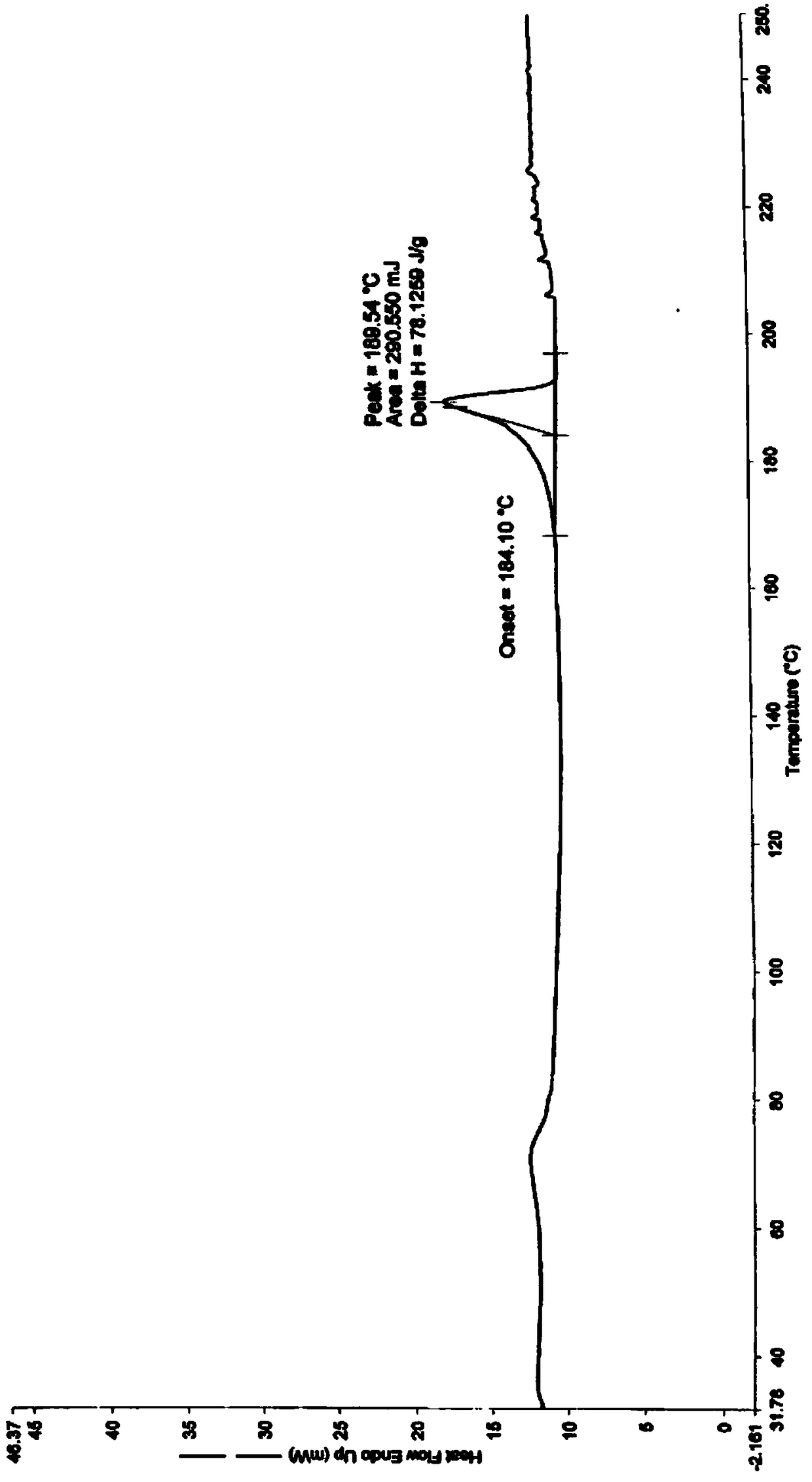

[0036] The cefadroxil prepared in this example has an X-ray powder diffraction pattern measured by Cu-Kα rays at 2θ of 4.27±0.2°, 8.52±0.2°, 17.13±0.2°, 19.92±0.2°, 20.52±0.2° , 21.44±0.2°, 23.87±0.2°, 25.09±0.2°, 25.85±0.2°, 29...

Embodiment 2

[0037] The preparation of embodiment 2 cefadroxil of the present invention

[0038] (1) Dissolve 100 g of cefadroxil crude product in 600 mL of mixed solvent A of tetrahydrofuran and water with a volume ratio of 1:2, and add ammonia water dropwise to adjust the pH value to 8.2;

[0039] (2) Filter, add dropwise acetic acid to the filtrate to adjust the pH value to 7.0, then slowly add 240ml dropwise of a mixed solvent B of 2-butanone and chloroform with a volume ratio of 1:0.3, stir while adding, and the stirring speed is 15 rpm / Minute;

[0040] (3) Cool down to -10°C, crystallize, and grow crystals for 2 hours;

[0041] (4) Filtrate to obtain a solid, and dry it under reduced pressure at 30° C. for 2 hours to obtain 97.31 mg of cefadroxil.

[0042] The X-ray powder diffraction pattern and differential scanning calorimetry pattern of the cefadroxil prepared in this embodiment are the same as those in Example 1, and its purity as determined by high performance liquid chromat...

Embodiment 3

[0043] The preparation of embodiment 3 cefadroxil of the present invention

[0044] (1) Dissolve 100 g of cefadroxil crude product in 1000 mL of mixed solvent A of tetrahydrofuran and water at a volume ratio of 1:2, and add ammonia water dropwise to adjust the pH value to 7.6;

[0045] (2) Filter, add dropwise acetic acid to the filtrate to adjust the pH value to 6.5, then slowly add 400ml dropwise of a mixed solvent B of 2-butanone and chloroform with a volume ratio of 1:0.3, stir while adding, and the stirring speed is 25 rpm / Minute;

[0046] (3) Cool down to 0°C, crystallize, and grow crystals for 6 hours;

[0047] (4) Filtrate to obtain a solid, and dry under reduced pressure at 40°C for 4 hours to obtain 96.27 mg of cefadroxil.

[0048] The X-ray powder diffraction pattern and differential scanning calorimetry pattern of the cefadroxil prepared in this embodiment are the same as those in Example 1, and its purity as determined by high performance liquid chromatography ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com