Preparation method of composite metal anode for secondary battery and product thereof

A composite metal, secondary battery technology, applied in electrode manufacturing, battery electrodes, electrode extrusion, etc., can solve the problems of adverse effects on metal electrode performance, difficulty in large-scale production, volume expansion, etc., to reduce volume expansion and raw materials. cost, the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

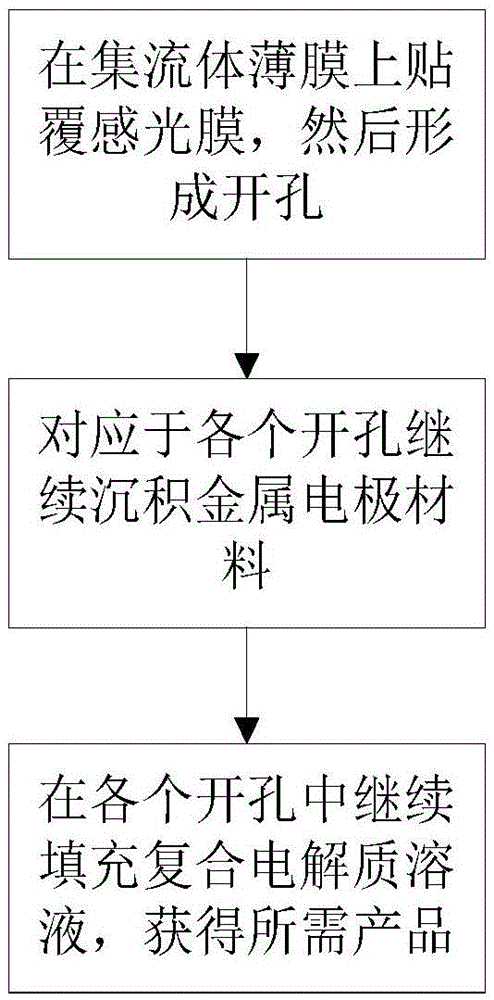

[0044] Specifically, for the preparation process of the composite metal electrode for secondary batteries according to the present invention, the preparation method proposed by the present invention is as follows figure 1 shown, and specifically includes the following steps:

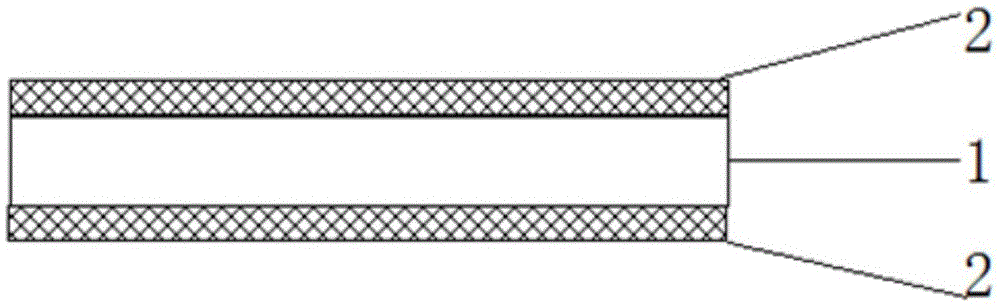

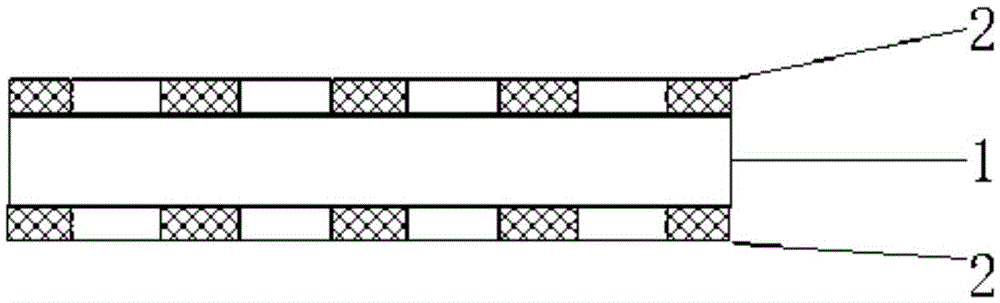

[0045] First, if figure 2 As shown, the surface of the film made of the current collector is cleaned, and then the photosensitive film is fully attached to its front and back sides; then, as Figure 3a and 3b As shown, for example, using a mask and undergoing exposure, development and curing treatments, a plurality of circular openings distributed in an array are formed on the photosensitive film, and the diameter of these circular openings is set to be 60 microns to 60 microns. 120 microns, and each exposes the current collector material located therebelow;

[0046] Next, see Figure 4a and 4b , on the surface of the exposed current collector material, continue to deposit the metal electrode mater...

Embodiment 1

[0051] Weigh the appropriate ratio of polyethylene oxide (PEO), LiPF 6 , Li 3 N nano-powders, and these three were added to THF solvent for dissolution and dispersion for 12 hours, and ultrasonic dispersion was performed with 100W ultrasonic power for 30 minutes in the middle; for high molecular polymers and alkali metal salts, the oxygen in the former The molar ratio between the element and the alkali metal in the latter was set at 10; the Li 3 The average particle size of the N nanometer powder is 100 nanometers, and it is set to account for 20% of the total weight percentage of the high molecular polymer and the alkali metal salt, thereby preparing the required composite electrolyte solution for use.

Embodiment 2

[0053] Weigh polyacrylonitrile, sodium hexafluorophosphorus, Al 2 o 3 Nano-powder, and these three were added to acetonitrile solvent for dissolution and dispersion for 12 hours, and ultrasonic dispersion was performed with 200W ultrasonic power for 15 minutes in the middle; for high molecular polymers and alkali metal salts, the oxygen element in the former The molar ratio with the alkali metal in the latter is set to 6; the Al 2 o 3 The average particle size of the nanometer powder is 200 nanometers, and it is set to account for 35% of the total weight percentage of the high molecular polymer and the alkali metal salt, thereby preparing the required composite electrolyte solution for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com