Damping resistor

A damping resistance and resistance technology, applied in the direction of resistors, resistance terminals/electrodes, non-adjustable metal resistors, etc., can solve the problems of enlarged structure, insignificant effect, increased processing and manufacturing costs, etc., to prevent resonance and reduce interference Intensity, attenuating the effect of high frequency oscillations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Before installing the high-voltage line, the resistor needs to be pre-oxidized. The steps of the treatment are:

[0020] (1) The wire core 4 made of nickel-chromium-lead alloy material is mechanically polished to remove the oxide film naturally formed on the surface of the nickel-chromium-lead alloy material;

[0021] (2): Put the nickel-chromium-lead alloy into the polishing solution at a temperature of 50°C for 1 minute, and the polishing solution is composed of H with a relative density of 1.7 3 PO 4 solution and H with a relative density of 1.85 2 SO 4 The solution is configured with a volume ratio of 1:1;

[0022] (3): Place the polished nickel-chromium-lead alloy in dry air and heat it to 100°C, keep it warm for 5 hours, and then cool it in the furnace;

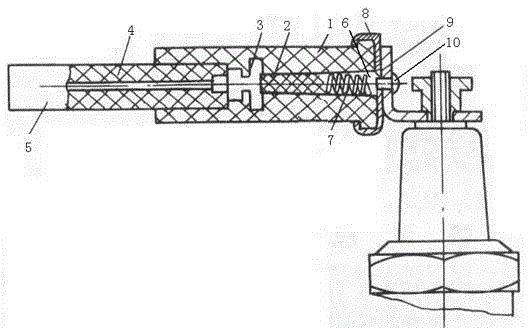

[0023] The left end of the wire core 4 after pre-oxidation treatment is fastened with the screw 3. The outer surface of the wire core 4 is covered with a layer of high-voltage wire 5, and the outer side of th...

Embodiment 2

[0025] Before installing the wire, the resistor needs to be pre-oxidized. The steps are:

[0026] (1) The wire core 4 made of nickel-chromium-lead alloy material is mechanically polished to remove the oxide film naturally formed on the surface of the nickel-chromium-lead alloy material;

[0027] (2): Put the nickel-chromium-lead alloy into the polishing solution with a temperature of 60°C for 1.5 minutes. The polishing solution is composed of H with a relative density of 1.7 3 PO 4 solution and H with a relative density of 1.85 2 SO 4 The solution is configured with a volume ratio of 1:1.1;

[0028] (3): Place the polished nickel-chromium-lead alloy in dry air and heat it to 150°C, keep it warm for 8 hours, and then cool it in the furnace;

[0029] The left end of the wire core 4 after pre-oxidation treatment is fastened with the screw 3. The outer surface of the wire core 4 is covered with a layer of high-voltage wire 5, and the outer side of the screw 3 is covered with a...

Embodiment 3

[0031] Before installing the wire, the resistor needs to be pre-oxidized. The steps are:

[0032] (1) The wire core 4 made of nickel-chromium-lead alloy material is mechanically polished to remove the oxide film naturally formed on the surface of the nickel-chromium-lead alloy material;

[0033] (2): Put the nickel-chromium-lead alloy into the polishing solution with a temperature of 80°C for 2 minutes. The polishing solution is composed of H with a relative density of 1.7 3 PO 4 solution and H with a relative density of 1.85 2 SO 4 The solution is configured with a volume ratio of 1:1.2;

[0034] (3): Place the polished nickel-chromium-lead alloy in dry air and heat it to 200°C, keep it warm for 10 hours, and then cool it in the furnace;

[0035] The left end of the wire core 4 after pre-oxidation treatment is fastened with the screw 3. The outer surface of the wire core 4 is covered with a layer of high-voltage wire 5, and the outer side of the screw 3 is covered with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com