Multi-core electrotechnical cable

An electrical and cable technology, applied in the field of multi-core electrical cables, can solve the problems of waste of funds, aggravate the congestion of pipeline laying, etc., and achieve the effect of protecting raw materials, ensuring electrical conductivity requirements, and ensuring toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

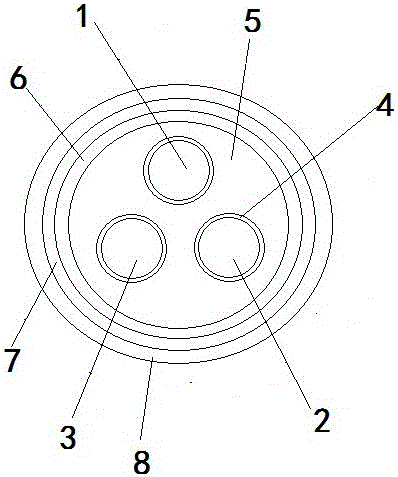

[0024] A multi-core electrical cable, including an iron-based alloy core material, an aluminum-based alloy core material and a copper-based alloy core material, each of the three core materials is coated with a moisture-proof layer to form three independent conductive core blanks, and the three core blanks Wrapped into a whole by the filler, the filler is covered with aluminum alloy wire shielding mesh, the aluminum alloy wire shield is covered with light fiber braided mesh, and the lightweight braided mesh is covered with cable material layer.

[0025] The content of each element component of the aluminum-based alloy core material is: Si1﹪, Sn0.8﹪, Nb0.6﹪, Cu0.5﹪, Cr0.3﹪, V0.2﹪, Mo0.06﹪, Ag0.05﹪, Ce0.04﹪, Pr0.03﹪, Cd0.01﹪, the balance is Al,

[0026] The content of each element component of the copper-based alloy core material is: Co2﹪, Zn0.7﹪, Ag0.4﹪, Ta0.3﹪, Ga0.2﹪, In0.1﹪, Ni0.07﹪, Sc0.04﹪, Ca0.03﹪, La0.03﹪, W0.01﹪, the balance is Cu,

[0027] The content of each element...

Embodiment 2

[0032] A multi-core electrical cable, including an iron-based alloy core material, an aluminum-based alloy core material and a copper-based alloy core material, each of the three core materials is coated with a moisture-proof layer to form three independent conductive core blanks, and the three core blanks Wrapped into a whole by the filler, the filler is covered with aluminum alloy wire shielding mesh, the aluminum alloy wire shield is covered with light fiber braided mesh, and the lightweight braided mesh is covered with cable material layer.

[0033] The content of each element component of the aluminum-based alloy core material is: Si2﹪, Sn0.9﹪, Nb0.7﹪, Cu0.6﹪, Cr0.4﹪, V0.3﹪, Mo0.07﹪, Ag0.06﹪, Ce0.05﹪, Pr0.04﹪, Cd0.02﹪, the balance is Al,

[0034] The content of each element component of copper-based alloy core material is: Co3﹪, Zn0.8﹪, Ag0.5﹪, Ta0.4﹪, Ga0.3﹪, In0.2﹪, Ni0.08﹪, Sc0.05﹪, Ca0.04﹪, La0.04﹪, W0.02﹪, the balance is Cu,

[0035] The content of each element com...

Embodiment 3

[0040] A multi-core electrical cable, including an iron-based alloy core material, an aluminum-based alloy core material and a copper-based alloy core material, each of the three core materials is coated with a moisture-proof layer to form three independent conductive core blanks, and the three core blanks Wrapped into a whole by the filler, the filler is covered with aluminum alloy wire shielding mesh, the aluminum alloy wire shield is covered with light fiber braided mesh, and the lightweight braided mesh is covered with cable material layer.

[0041] The content of each element component of the aluminum-based alloy core material is: Si1.5﹪, Sn0.85﹪, Nb0.65﹪, Cu0.55﹪, Cr0.35﹪, V0.25﹪, Mo0.065﹪, Ag0.055 ﹪, Ce0.045﹪, Pr0.035﹪, Cd0.015﹪, the balance is Al,

[0042] The content of each element component of the copper-based alloy core material is: Co2.5﹪, Zn0.75﹪, Ag0.45﹪, Ta0.35﹪, Ga0.25﹪, In0.15﹪, Ni0.075﹪, Sc0.045 ﹪, Ca0.035﹪, La0.035﹪, W0.015﹪, the balance is Cu,

[0043] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com