Method and device for purifying and recycling cleaning waste gas of hot cell of fusion reactor by cryogenic rectification

A fusion reactor heat chamber and cryogenic technology, which is applied in the field of radioactive pollution control and treatment, can solve the problems that the detritium removal system cannot handle a large amount of carbon dioxide gas, and the cleaning and decontamination of tritium retained parts, etc. It is simple and easy to achieve equipment and liquefaction conditions , The effect of long equipment maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to more clearly express the objectives, technical solutions, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

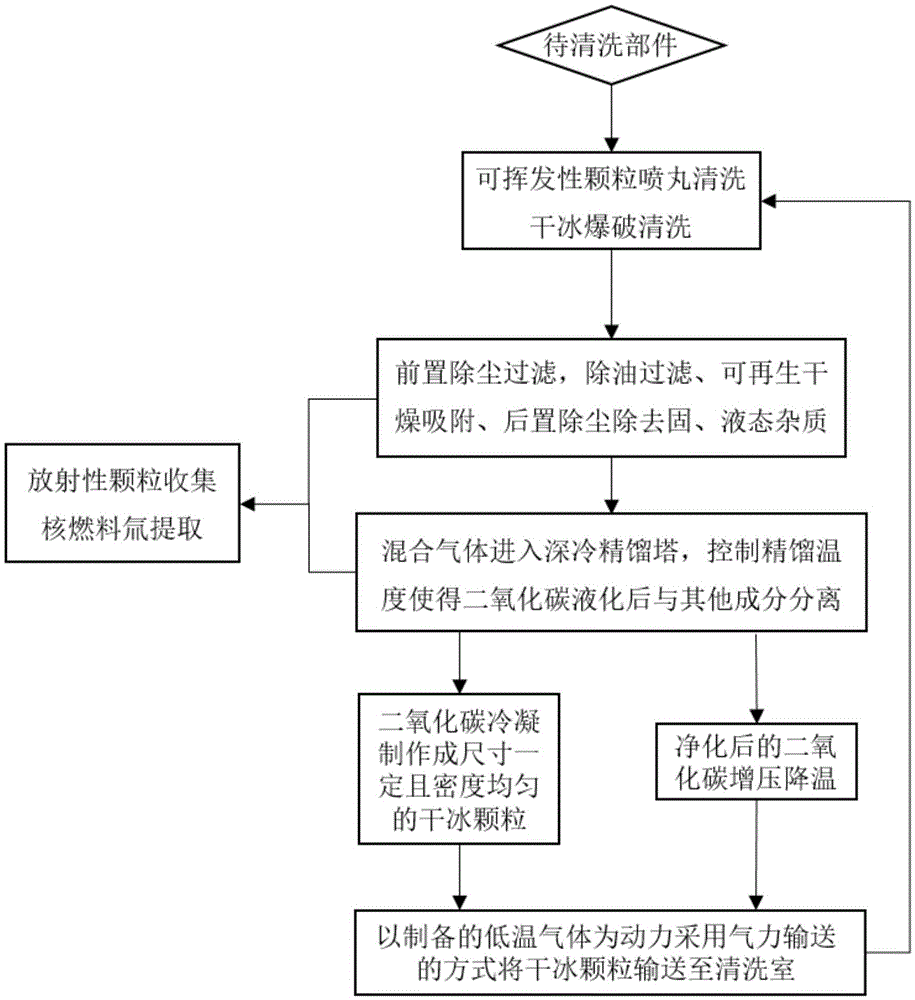

[0035] Such as figure 1 As shown, the parts to be cleaned are transported from the remote operation device to the hot chamber cleaning unit, and the transport device transports the parts to be cleaned to the bottom of the ejector. The ejector ejects high-speed dry ice particles to cause adhesion and weak solid pollution on the surface of the parts to be cleaned. The substance is separated from the substrate. After completing a cleaning task, the inside of the cleaning unit is sprayed and purged. The dust-laden exhaust gas after cleaning is successively filtered through the pre-dust fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com