Photomask blank, resist pattern forming process, and method for making photomask

A photomask and resist film technology, applied in the field of photomask blanks, can solve problems such as difficulty in meeting aging stability and resolution, and achieve the effect of improving aging stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0288] Synthesis examples, preparation examples, examples, reference examples and comparative examples are given below to further illustrate the present invention, although the present invention is not limited thereto. Mw is the weight average molecular weight determined by GPC using tetrahydrofuran solvent relative to polystyrene standards. pass 1 The compositional ratio of the polymer was analyzed by H-NMR.

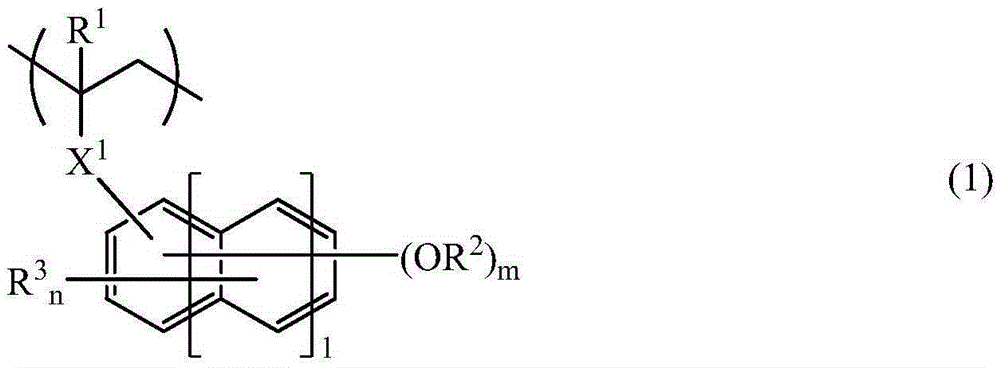

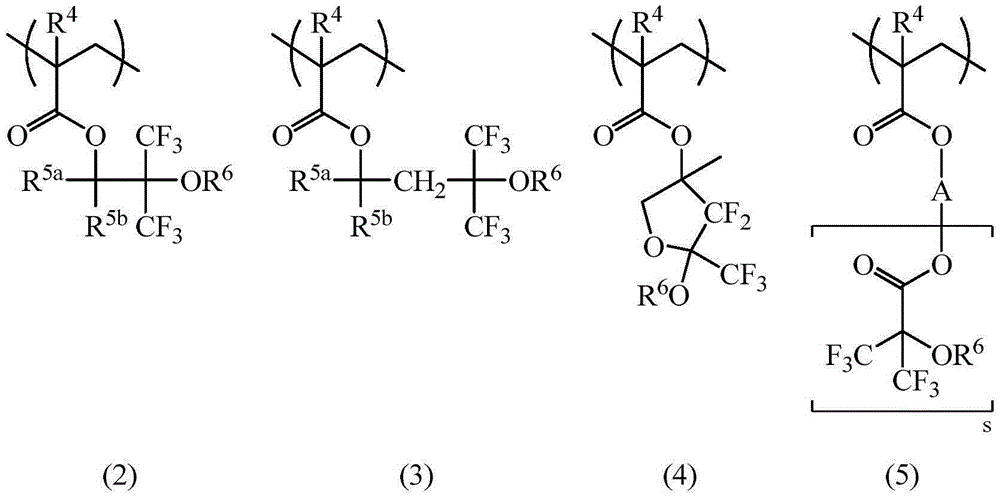

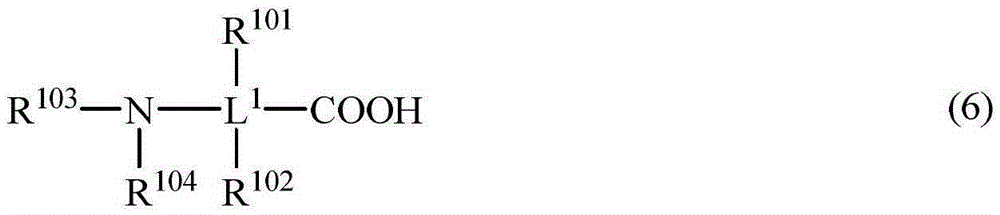

[0289] The polymerizable monomer (monomer 1-6) used in the synthesis example has the following structural formula.

[0290]

[0291] Monomers 1, 2, 4 and 5 were synthesized according to the teachings of JP-A2007-204385, JP-A2007-204448, JP-A2012-032762 and JP-A2008-111103. Monomers 3 and 6 are commercially available from Tokyo Chemical Industry Co., Ltd.

Synthetic example 1

[0293] Synthesis of Polymer A1

[0294] In a nitrogen atmosphere, 87 g of monomer 1, 13 g of monomer 2 and 4.3 g of dimethyl 2,2'-azobisisobutyrate were dissolved in 155 g of methyl ethyl ketone and toluene in 7 / 3 in the mixture. This solution was added dropwise to 78 g of a 7 / 3 mixture of methyl ethyl ketone and toluene under stirring at 80° C. over 4 hours in a nitrogen atmosphere. At the end of the dropwise addition, the solution was aged at 80° C. for 2 hours. The polymerization solution was cooled to room temperature and added dropwise to 1,500 g of hexane. The solid precipitate was filtered, washed with 600 g of hexane, and vacuum dried at 60° C. for 20 hours to obtain a white solid powdery polymer. A polymer having the following formula is denoted as Polymer A1. Quantity 70g, yield 70%.

[0295]

Synthetic example 2、3

[0296] Synthesis Examples 2, 3 and Comparative Synthesis Examples 1, 2

[0297] Synthesis of polymers A2, A3 and comparative polymers A4, A5

[0298] Polymers A2, A3 and comparative polymers A4, A5 were synthesized by the same procedure as in Synthesis Example 1, except that the types and ratios of the monomers and the ratio of the solvent mixture were changed.

[0299]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com