Method for simultaneously detecting six sweetening agents in feed additive with high performance liquid chromatograph

A technology of high performance liquid chromatography and feed additives, which is applied to the detection of sweeteners. High performance liquid chromatography can detect six kinds of sweeteners in feed additives at the same time. and other problems, to achieve the results of accurate and reliable detection results, excellent separation effect, and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

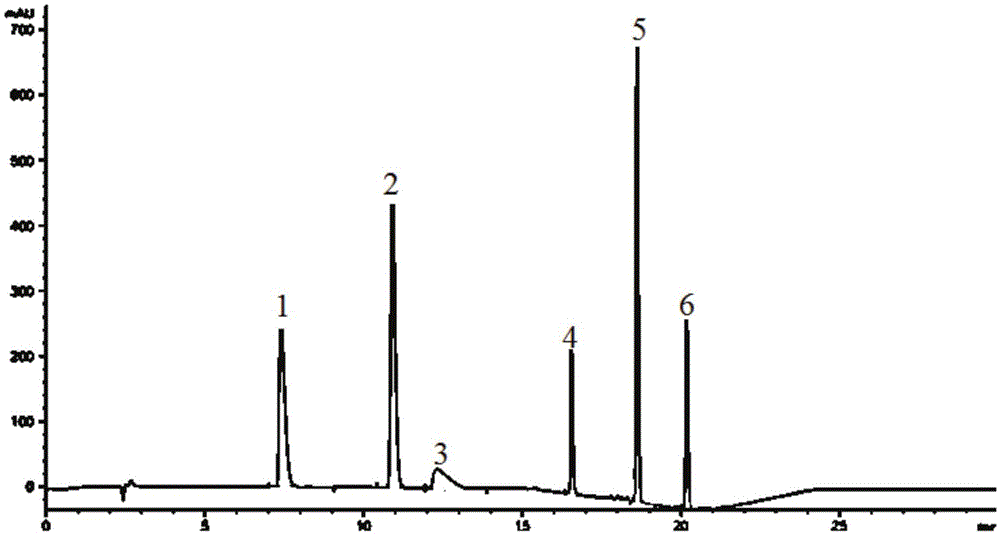

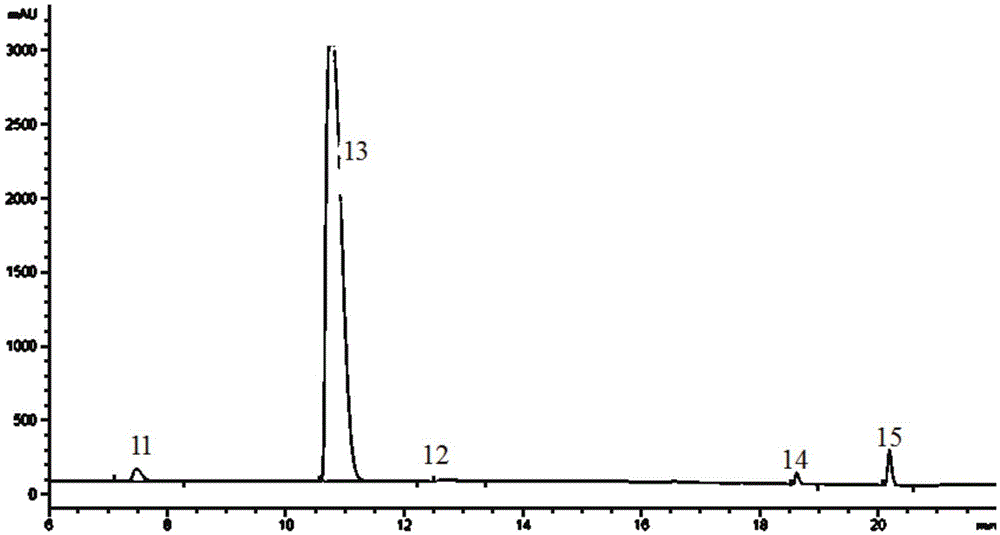

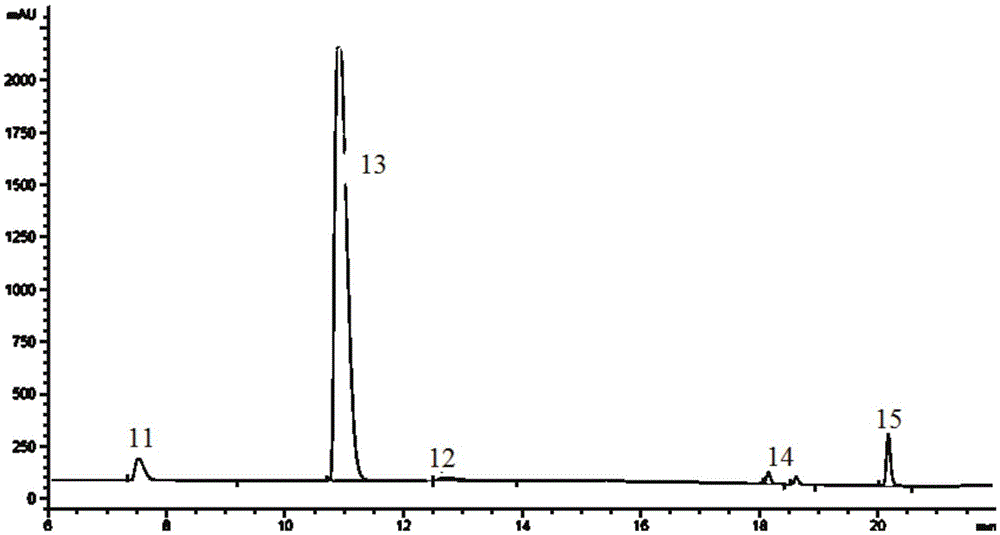

[0043] Example 1: Detection of 3 commercially available feed sweeteners

[0044] 1. Reagents and Materials

[0045] Unless otherwise specified, the reagents used in this determination method are analytically pure, and the water is the secondary water specified in GB / T6682.

[0046] 1.1 Methanol: chromatographically pure

[0047] 1.2 Acetonitrile: chromatographically pure

[0048] 1.3 Ammonium sulfate: superior grade

[0049] 1.4A-K sugar standard: 98.0%, Tokyo Chemical Industry Co., Ltd.

[0050] 1.5 Sodium Saccharin Standard: 99.0%, Dr.Ehrenstorfer Company, Germany

[0051] 1.6 Standard product of cyclamate: 98.0%, Tokyo Chemical Industry Co., Ltd.

[0052] 1.7 Aspartame standard product: 98.0%, Tokyo Chemical Industry Co., Ltd.

[0053] 1.8 New methyl hesperidin dihydrochalcone standard: 98.0%, CNW Technologies GmbH, Germany

[0054] 1.9 Neotame Standard: 98.0%, Tokyo Chemical Industry Co., Ltd.

[0055] 1.10 Mixed standard stock solution: Accurately weigh 0.1000g A-K ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com