Preparation method of diamond/tialn composite coating on the surface of cemented carbide tool

A cemented carbide and composite coating technology, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problems of uneven surface of composite coating, short service life, easy wear of tools, etc. Achieve excellent cutting performance, high cutting temperature, and improved working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

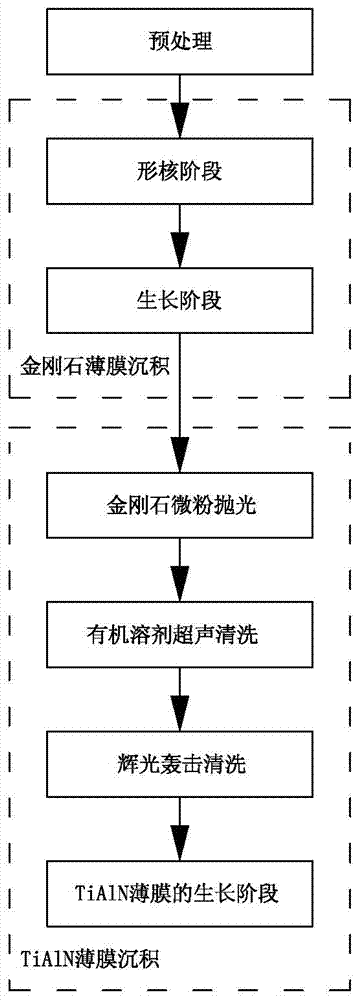

Method used

Image

Examples

Embodiment 1

[0030] Deposit the diamond / TiAlN composite coating on the surface of the special cemented carbide end mill for the aluminum alloy profile of the high-speed train body. The tool diameter is 32mm, the blade length is 80mm, and the length is 110mm. The specific steps are as follows:

[0031] (1) Soak the blade part of the cemented carbide tool in the Murakami solution for 30 minutes of ultrasonic cleaning, which will fragment the tungsten carbide (WC) particles on the surface of the cemented carbide and cause the surface of the substrate to roughen. The components of Murakami solution are potassium hydroxide (KOH), potassium ferricyanide (K 3 (Fe(CN) 6 )) and water (H 2 O), its mass ratio is KOH: K 3 (Fe(CN) 6 ): H 2 O = 1:1:10. Then the cemented carbide substrate was soaked in Caro mixed acid solution and etched for 1 minute to remove the cobalt element on its surface. The composition of Caro's mixed acid solution is concentrated sulfuric acid (H 2 SO 4 ) and hydrogen pe...

Embodiment 2

[0040] The diamond / TiAlN composite coating is deposited on the surface of the cemented carbide indexable turning insert for processing SiC particle reinforced aluminum matrix composite materials. The specific steps are as follows:

[0041] (1) Carbide indexable turning inserts were subjected to acid-alkali pretreatment by the same method as in Example 1.

[0042] (2) Place the pretreated cemented carbide indexable turning blade in the reaction chamber of the hot wire CVD equipment for the nucleation stage of depositing the diamond film. During the deposition process, the turning blade is supported by a stainless steel column with steps, and the stainless steel column is inserted on a copper block with a through hole, which not only stabilizes its supporting role, but also enhances the thermal conductivity. The hot wire is placed on both sides of the tool, and the deposition parameters used in the nucleation stage are: methane flow rate is 16 sccm, hydrogen flow rate is 800 scc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com