Large steel welded vertical oil tank

A vertical and large-scale technology, applied in the direction of large-scale containers, containers, packaging, etc., can solve the problems of safe operation hazards, catastrophic environmental damage, low-cycle fatigue damage of large-scale oil tanks, eliminate major danger points, and improve fatigue resistance. The effect of improving ability and stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments.

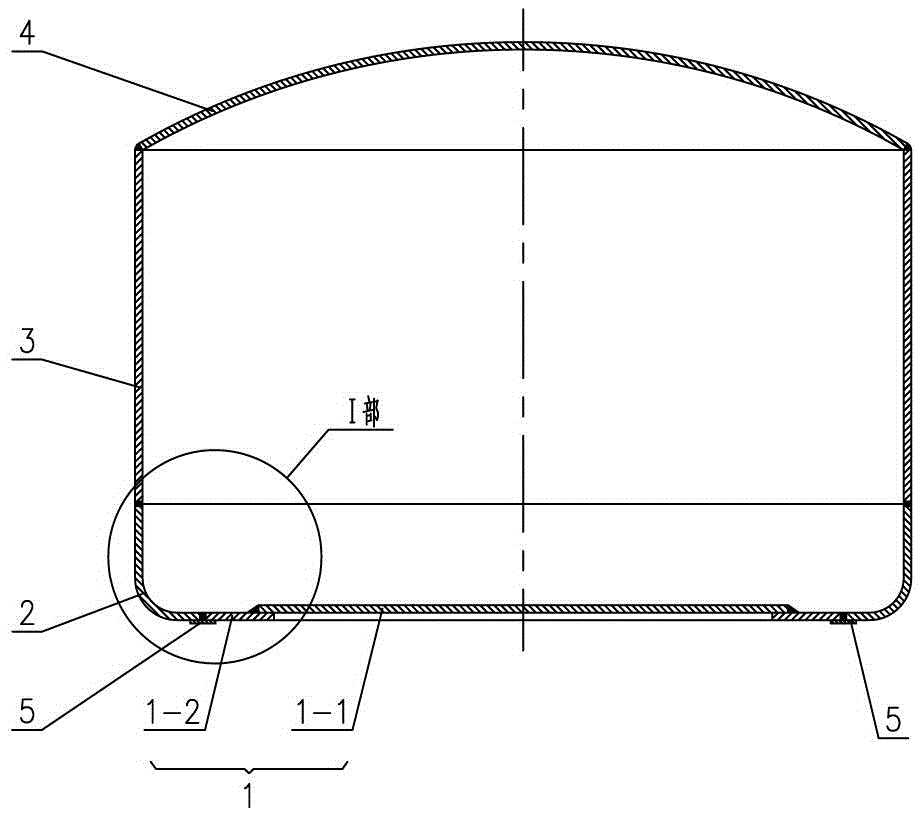

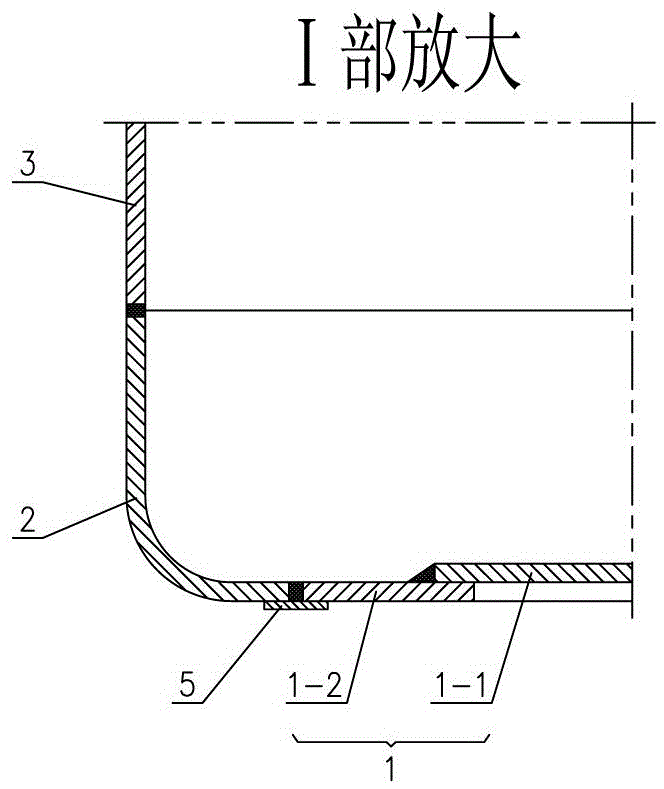

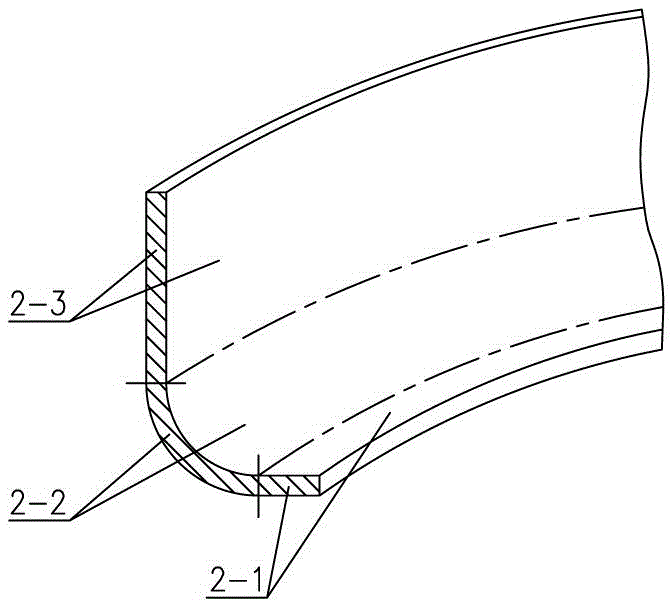

[0033] like figure 1 , 2 , 3, 4, 5, 6, and 7, a welded steel vertical large-scale oil tank has a tank bottom 1, a tank wall 3 and a tank top 4, and there is a transition between the tank bottom 1 and the tank wall 3 The connecting ring 2, the transition connecting ring 2 has a bottom ring section 2-1, an arc transition section 2-2 and a vertical cylindrical section 2-3, the tank bottom 1 and the bottom ring section 2 of the transition connecting ring 2 -1 welded connection, the tank wall 3 is welded to the vertical cylindrical section 2-3 of the transition ring 2.

[0034] like figure 1 , 2 , 6, the tank bottom 1 is lapped and welded by the middle plate 1-1 and the annular edge plate 1-2, of course, it can also be as follows Figure 4 , 5 , 7, the tank bottom 1 is butt welded by the middle plate 1-1 and the annular edge plate 1-2, and a back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com