bearing ring

A technology of bearing rings and rolling bearings, applied in the field of rolling bearings, can solve the problems of increased edge stress, increased pressure loading of rolling elements, and reduced loadability of rolling bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

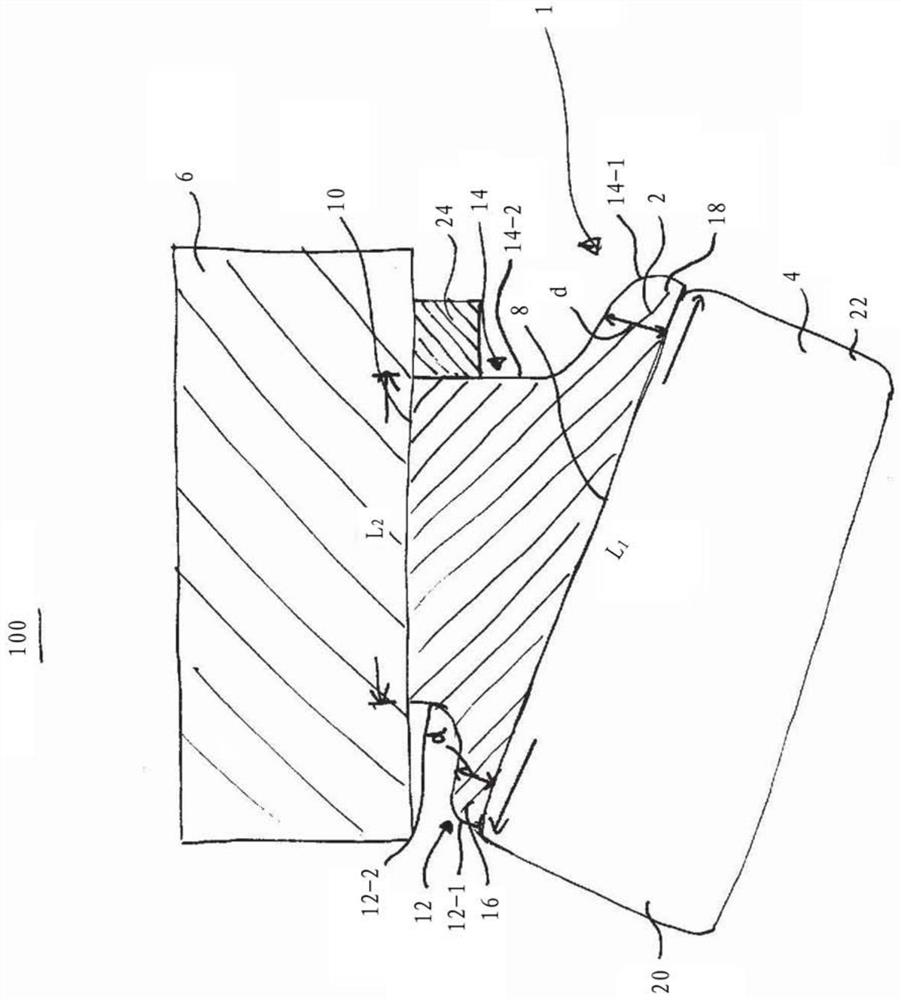

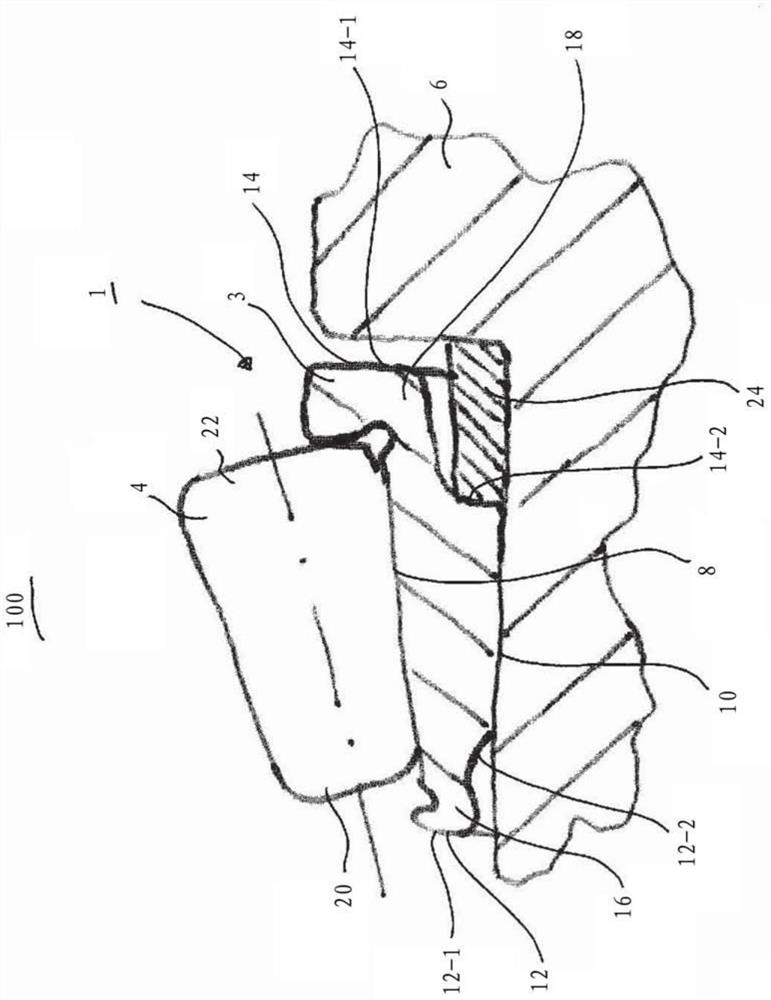

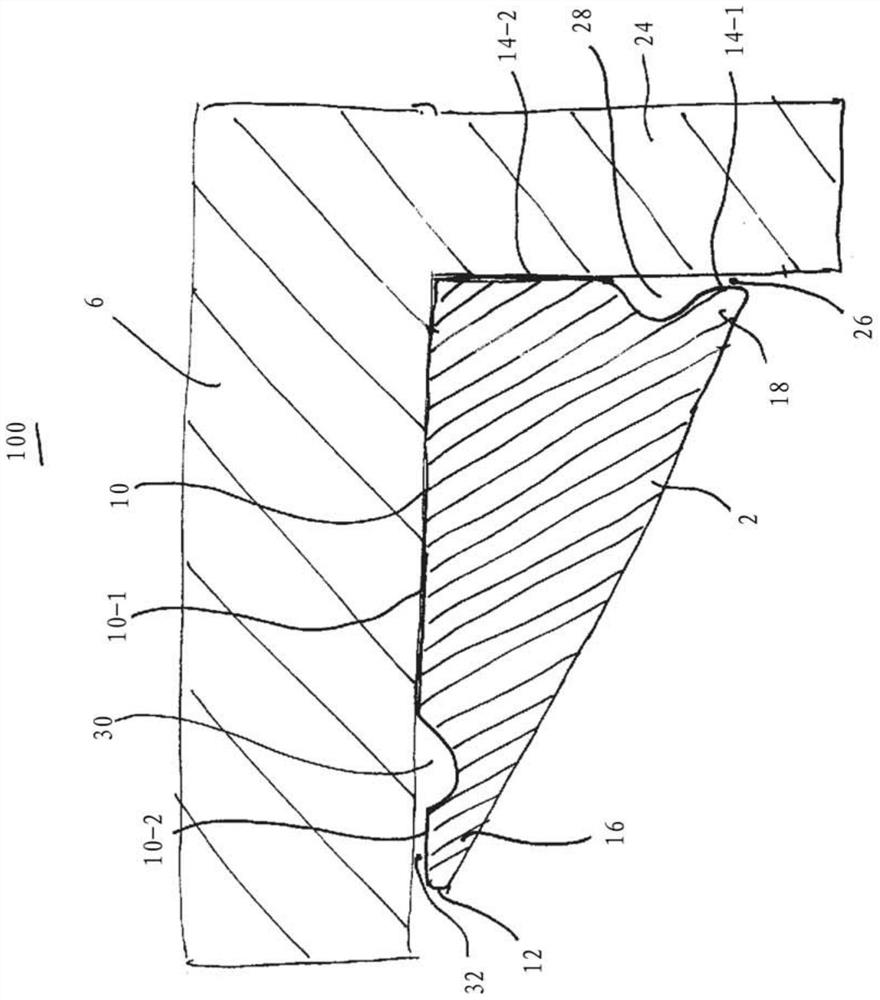

[0022] figure 1 Schematically shows a section through a part of a rolling bearing arrangement 100 with a rolling bearing 1 designed as a tapered roller bearing, only schematically showing the bearing ring 2 in the form of an outer ring designed according to the invention and rolling body 4. As shown, the rolling bearing 1 , more precisely the outer ring 2 , is accommodated in a housing 6 with a press fit.

[0023] The bearing outer ring 2 itself has a running surface 8 on which the rolling bodies 4 are guided in a rolling manner. In addition, the outer ring 2 has an outer surface 10 which contacts the housing 6 , wherein the outer ring 2 is typically housed in the housing 6 under a press fit. The bearing outer ring 2 is delimited laterally by edge faces 12 , 14 which provide an axial delimitation of the bearing ring 2 .

[0024] in addition figure 1 It is shown that flexible edges 16 , 18 are formed on the bearing outer ring 2 , which can move elastically in the direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com