Ceramic body pulverizing, granulating and drying method

A technology for ceramic blanks and granulation, which is applied to manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of long production cycle, complex process, large investment, etc., and achieves reduced production cost, simple equipment structure, and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

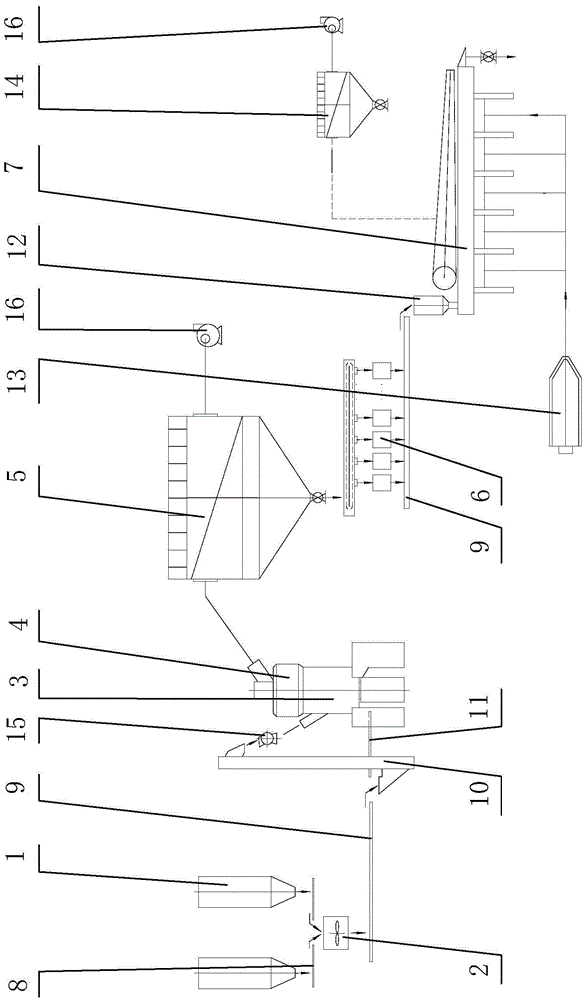

[0021] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0022] The method for milling, granulating, and drying ceramic blanks of the present invention comprises the following process steps:

[0023] Step 1: Use a stone crusher (jaw crusher or impact crusher, etc.) to crush the ore raw materials transported from the mine into crushed stone raw materials with a size ≤ 30mm, and send the crushed stone raw materials with different components to two More than two different raw material tanks 1 are stored for use.

[0024] Step 2: The crushed stone raw materials in each raw material tank 1 are transported to the homogenizer 2 (mixer) in proportion through the corresponding quantitative conveying belt conveyor 8 for homogenization (uniform mixing and stirring).

[0025] Step 3: The homogenized mixed material is transported to the hoist 10 through the belt conveyor 9, and the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com