Rapid multifunctional electronic component temperature characteristic measuring instrument and testing cavity

A technology of electronic components and temperature characteristics, applied in the electronic field, can solve the problems of limited heating temperature range, slow system response speed, large volume, etc., and achieve the effects of reduced equipment volume, high degree of automation, and small equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

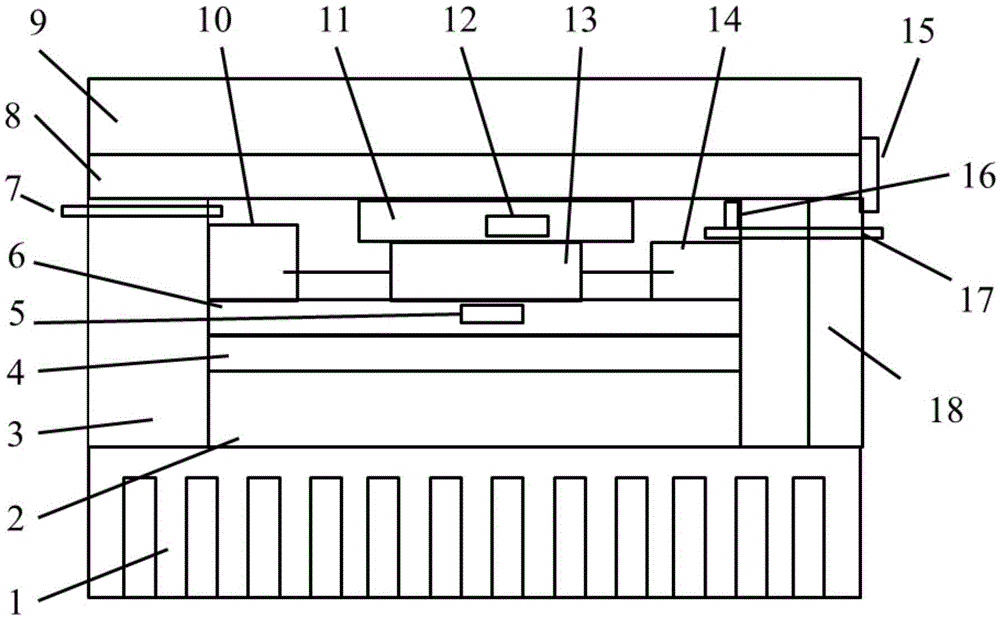

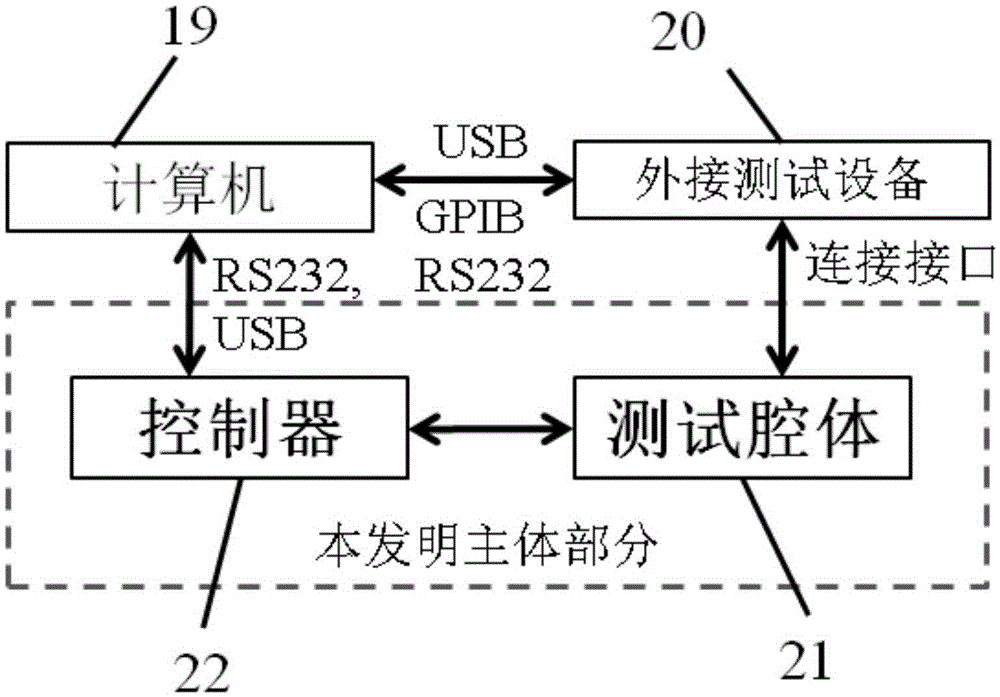

[0058] Embodiment 1: The controller 22 is connected to the test cavity 21 for measurement

[0059] When the pins of the sample to be tested are less than 4, the user selects the appropriate component bracket 13 to be tested according to the size of the sample to be tested or the component, installs it on the component bracket 13 to be tested, and inserts the component bracket 13 to be tested into the test cavity On the quick connection terminals (10, 14) in 21, cover the detachable cavity top cover 9 and fasten the clamp 15, confirm that the equipment is in normal working condition through the LCD, and remind the user to perform dehumidification operation if the detected humidity is too high . The user enters through the keyboard, selects the parameters to be measured, sets the temperature parameters, sets the test signal parameters, etc., and then starts the measurement. The controller 22 will control the temperature of the test chamber 21 according to the temperature set by...

Embodiment 2

[0060]Embodiment 2: The computer 19 is connected to the controller 22 to connect to the test cavity 21 for measurement

[0061] When the pins of the sample to be tested are less than 4, the user selects a suitable sample holder and the component to be tested bracket 13 according to the size of the sample to be tested or the component, installs it on the component to be tested bracket 13, and inserts the component to be tested bracket 13 into the test On the quick connection terminals (10,14) in the cavity (21), cover the cavity top cover 9 that the top cover can be separated and fasten the presser 15, and confirm the controller 22 and test by the special control program on the computer. The cavity 21 is in a normal working state, and if the detected humidity is too high, the user is reminded to perform a dehumidification operation. Through the computer program interface, the user selects the parameters to be measured, sets the temperature parameters, sets the test signal param...

Embodiment 3

[0062] Embodiment 3: Computer 19, external measuring equipment 20, controller 22 and test chamber 21 perform joint measurement

[0063] When the pins of the sample to be tested are less than 4, the user selects a suitable sample holder to be tested on the component bracket 13 according to the size of the sample to be tested or the component, installs it on the component to be tested bracket 13, and installs the component to be tested bracket 13 to the test On the quick connection terminals (10, 14) in the cavity (21), select the above-mentioned "2+1" external connection mode during installation, and connect to the three BNC interfaces on the external device connection interface on the outer wall of the cavity When the pins of the sample to be tested are greater than 3 and less than 13, the user selects the sample rack to be tested component support 13 that supports 12-pin connection according to the sample to be tested or the component size, and installs it on the component to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com