A production process and special device for non-woven filter material without base cloth

A special device and production process technology, applied in the direction of filtration and separation, membrane filter, non-woven fabrics, etc., can solve the problem of easy deformation of pre-needle felt without base fabric, and achieve simple production process, short production time and high production efficiency. time-controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

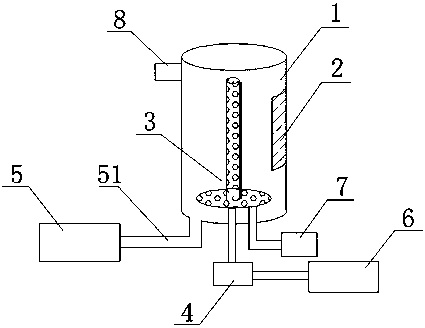

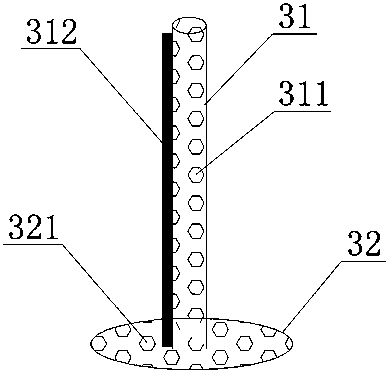

[0037] Example 1: A special device for opening fibers of pre-needled felt

[0038] combine figure 1 , figure 2 As shown, the present invention is a special device for opening fibers of pre-needled felt, comprising a cylinder body 1, the bottom of the cylinder body 1 is connected with a vacuum pump 5, a side door 2 and a feed port 8 are arranged on the cylinder body 1, and the cloth The cage 3 is installed in the cylinder body 1, the cloth cage 3 includes a chassis 32, and the small motor 7 is linked with the chassis 32. A number of small holes 311 are provided, and the cloth clamp 312 is installed on the center pipe 31 of the cloth cage. One end of the centrifugal pump 4 is connected with the central pipe 31 of the cloth cage, and the other end of the centrifugal pump 4 is connected with the driving motor 6 .

[0039] As a preferred embodiment, the cylinder body 1 is provided with a side door 2 on the side wall of the cylinder body 1 to facilitate the operation of feeding a...

Embodiment 2

[0046] Embodiment 2: a kind of production technology of base cloth nonwoven filter material

[0047] A kind of production technology of base cloth nonwoven filter material, it is characterized in that, comprises the following steps:

[0048] (1) Laying: Lay the net after evenly mixing the composite fiber and ordinary PPS fiber in proportion.

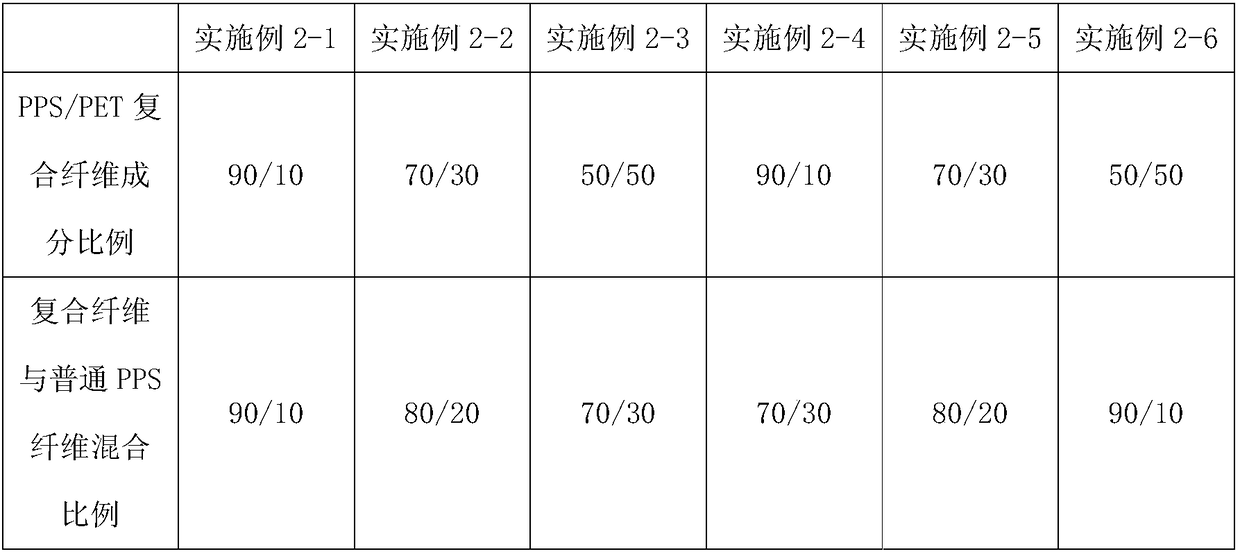

[0049] The composition ratio of the composite fiber and the mixing ratio of the composite fiber and common PPS fiber laying were changed, as shown in Example 2-1 to Example 2-6 of Table 1.

[0050] Table 1: Selection and ratio of different composite fibers

[0051]

[0052] Note: The composite fiber in Example 2-1~Example 2-3 is the sea-island type PPS / PET composite fiber; Example 2-4~

[0053] The composite fiber in embodiment 2-6 is split type PPS / PET composite fiber;

[0054] (2) Pre-acupuncture: Pre-needle the fibers laid out in step (1) into pre-needle felt without base fabric, and the needle density is: 100 needles / ㎝ 2 ;

...

Embodiment 3-1~ Embodiment 3-4

[0074] Technology is the same as embodiment 2, and difference is: change the process parameter of step (3) fiber opening, and statistics, analyze its performance impact on non-woven filter material without base cloth, specifically as follows:

[0075] (1) Laying net:

[0076] Evenly mix 70 / 30 island-in-the-sea composite fiber PPS / PET and ordinary PPS fiber in the ratio of 80 / 20, then lay the net, and lay it into a certain thickness according to actual needs;

[0077] (2) Pre-acupuncture: acupuncture density: 150 needles / ㎝ 2 .

[0078] (3) Fiber opening:

[0079] Open the side door 2 of the special device for fiber opening of the pre-needled felt, clamp the head of the non-base cloth pre-needled felt on the cloth cage central tube 31, and use the small motor 7 to make the cloth cage central tube 31 rotate at a certain speed, and evenly The non-base cloth pre-needle felt is wound onto the cloth cage central tube 31;

[0080] After closing the side door 2, add some caustic so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com