One-component titanate halogen-free flame-retardant silicone sealant

A technology of one-part titanate and sealant, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve problems such as unsatisfactory storage stability, improve storage stability and yellowing resistance, Effect of improving compatibility and improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

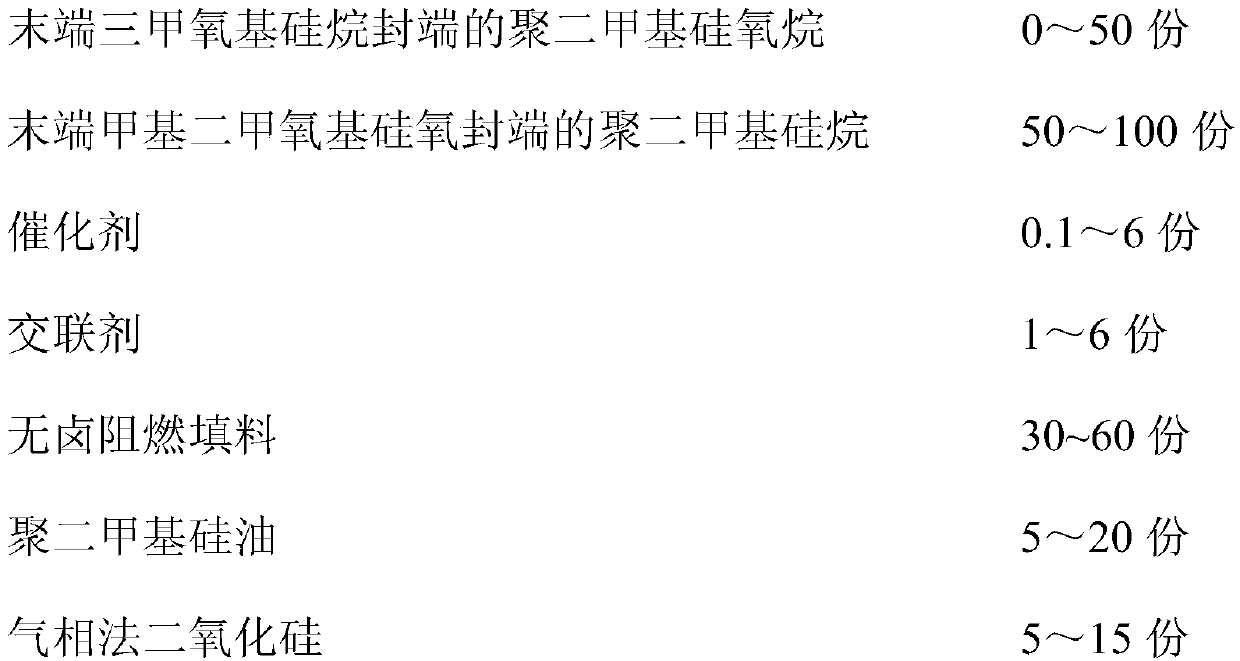

[0055] A one-component titanate halogen-free flame-retardant silicone sealant, which is mainly prepared from the following raw materials in parts by weight:

[0056]

[0057]

[0058] Wherein, the catalyst is a mixture of a primary titanium catalyst and a secondary titanium catalyst, and the primary titanium catalyst is tetra-tert-butyl titanate, and the secondary titanium catalyst is silicon titanate prepared by reacting isopropyl titanate with hydroxyl silicone oil. Oxyalkyl ester catalyst, and the mass ratio of primary titanium catalyst and secondary titanium catalyst is 0.5:1. The viscosity of polydimethylsiloxane terminated by trimethoxysilane at the end is 4000cps, the viscosity of polydimethylsiloxane terminated by methyldimethoxysilane at the end is 5000cps, and the crosslinking agent is methyl orthosilicate, The halogen-free flame retardant filler is silicone resin flame retardant, the viscosity of polydimethylsilicone oil is 50cps, the fumed silica is hydrophil...

Embodiment 2

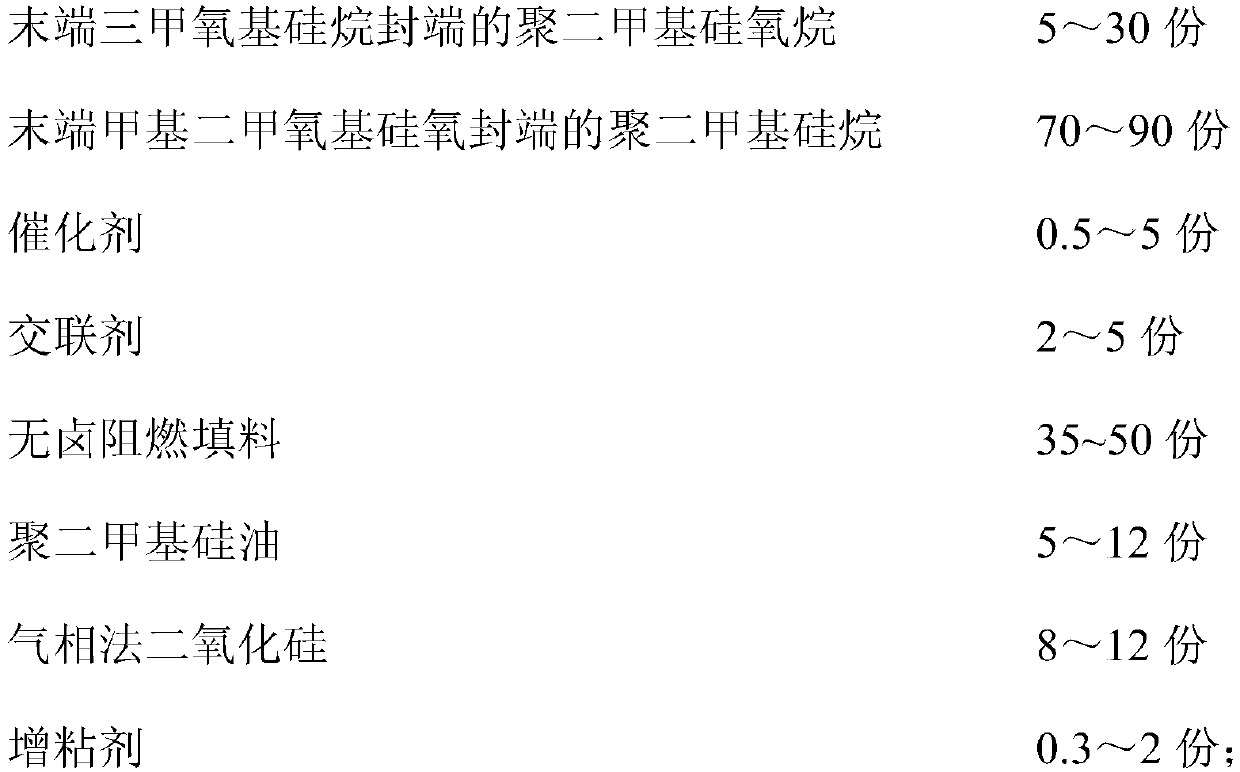

[0061] A one-component titanate halogen-free flame-retardant silicone sealant, which is mainly prepared from the following raw materials in parts by weight:

[0062]

[0063] Wherein, the catalyst is a mixture of a primary titanium catalyst and a secondary titanium catalyst, and the primary titanium catalyst is tetraisopropyl titanate, and the secondary titanium catalyst is made by reacting isopropyl titanate with hydroxyl silicone oil The siloxane titanate catalyst, and the mass ratio of the primary titanium catalyst to the secondary titanium catalyst is 4:1. The viscosity of polydimethylsiloxane end-capped by trimethoxysilane is 80000cps, the viscosity of polydimethylsiloxane end-capped by methyldimethoxysilane is 65000cps, and the crosslinking agent is methyltrimethoxysilane It is a mixture with vinyltrimethoxysilane, the halogen-free flame retardant filler is polysiloxane flame retardant, the viscosity of polydimethylsilicone oil is 2000cps, and the fumed silica is hydr...

Embodiment 3

[0066] A silicone sealant, which is mainly prepared from the following raw materials in parts by weight:

[0067]

[0068]Wherein, the catalyst is a mixture of a primary titanium catalyst and a secondary titanium catalyst, wherein the primary titanium catalyst is a mixture of tetra-tert-butyl titanate and tetraisopropyl titanate, and the secondary titanium catalyst is obtained through isopropyl titanate A siloxane titanate catalyst prepared by the reaction of ester and hydroxy silicone oil, and the mass ratio of the primary titanium catalyst to the secondary titanium catalyst is 0.5:1. The viscosity of the end-trimethoxysilane-terminated polydimethylsiloxane is 10000cps, the viscosity of the end-methyldimethoxysiloxane-terminated polydimethylsiloxane is 30000cps, and the crosslinking agent is vinyltriethoxy Silane, halogen-free flame retardant filler is a mixture of sodium hydroxide, phosphate ester and melamine, the viscosity of polydimethylsilicone oil is 100cps, the fume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com