Sterilization device used in shiitake mushroom industrial production

A sterilizing device and factory-like technology, applied in the fields of application, horticulture, botany equipment and methods, etc., can solve the problems of low production efficiency, high equipment idle rate, high labor intensity, etc., so as to improve the success rate of inoculation and reduce production costs , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

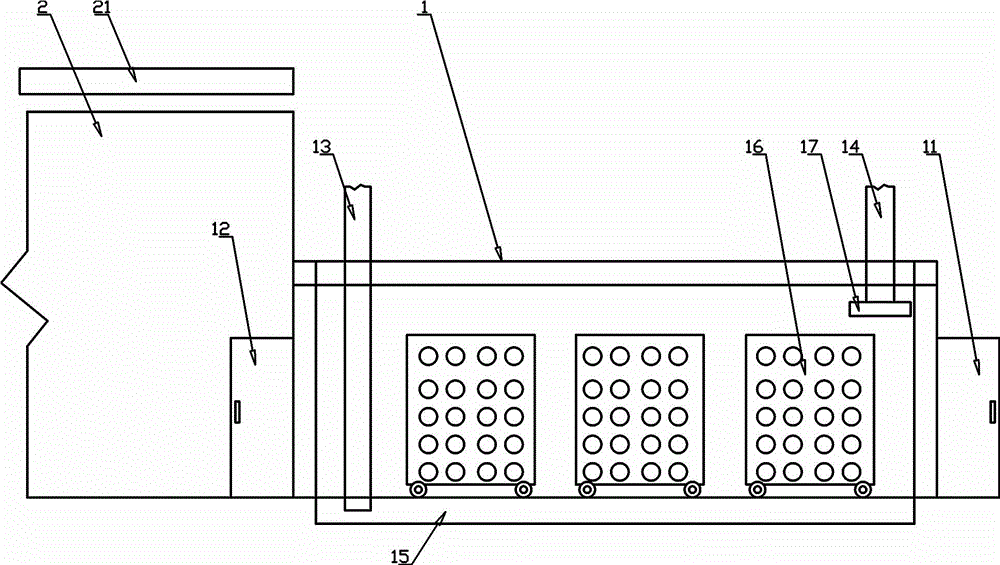

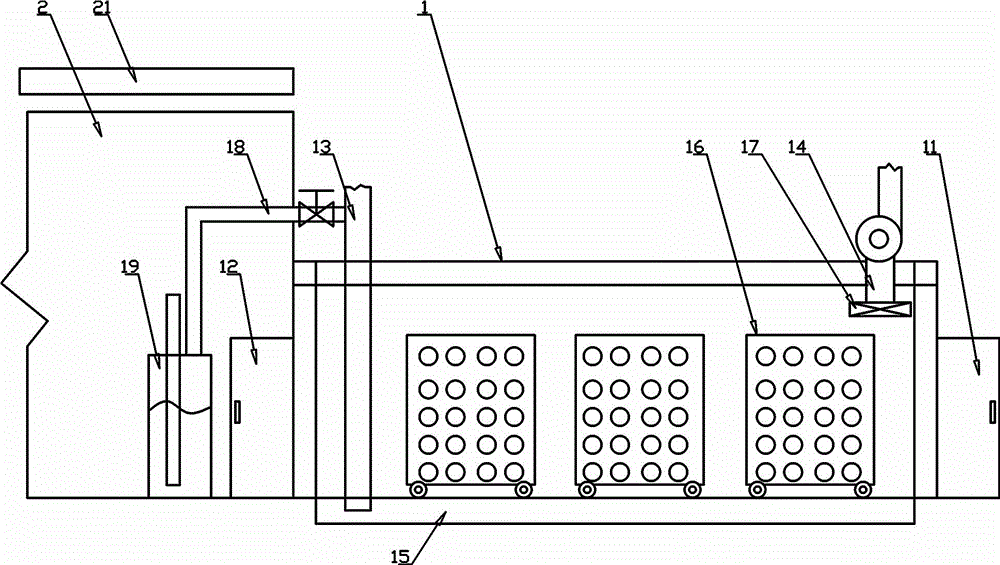

[0016] like figure 1 Among them, a sterilizing device for industrial production of shiitake mushrooms, comprising a sterilizing chamber 1, the two ends of the sterilizing chamber 1 are respectively provided with a first airtight door 11 and a second airtight door 12, wherein the first airtight door 11 is as close as possible to Bacteria tube bagging device, the second sealed door 12 is directly located in the inoculation workshop 2, and the sterilization room 1 is respectively provided with a steam inlet pipe 13 and a steam exhaust pipe 14. The top of the inoculation workshop 2 is provided with a shading layer 21, so that the bacterium tube can germinate under a cool condition. In this example, the steam temperature is 100-130°C, and the steam pressure is 0.015-0.05MPa. Because of the higher pressure and the sealed structure of the sterilization chamber, the sterilization time is shortened, only 16-18h. Compared with the traditional 24h sterilization time, the time is reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com