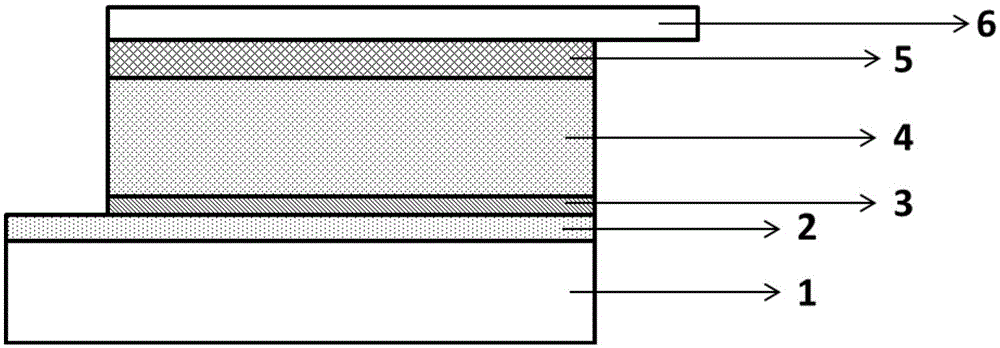

Method for preparing interface modified perovskite solar cell through vapor auxiliary solution method

A gas-phase auxiliary solution and solar cell technology, which is applied in the field of solar cells, can solve the problems affecting the photoelectric conversion efficiency of cells, and achieve the effects of improving photoelectric conversion efficiency and electrical performance, reducing hysteresis effect, and improving interface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

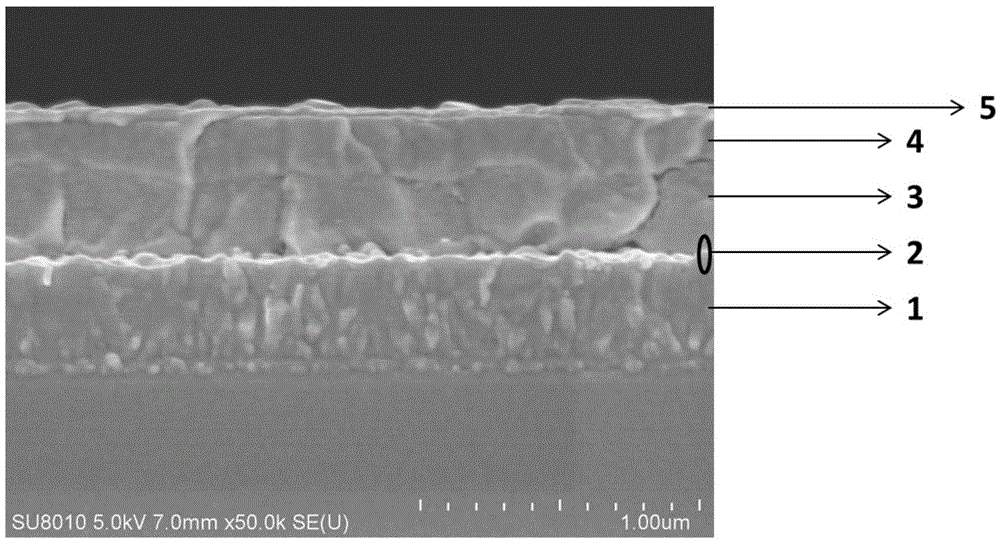

[0043] (1) At a speed of 3000rpm, the TiO 2 The solution was spin-coated on a clean FTO substrate and heated at 500°C for 30 minutes to obtain a barrier layer;

[0044] (2) With the rotating speed of 1500rpm, the concentration is 10mg / ml C 60 O-dichlorobenzene solution was spin-coated on the barrier layer, and then heated at 60°C for 2 minutes to obtain an interface modification layer;

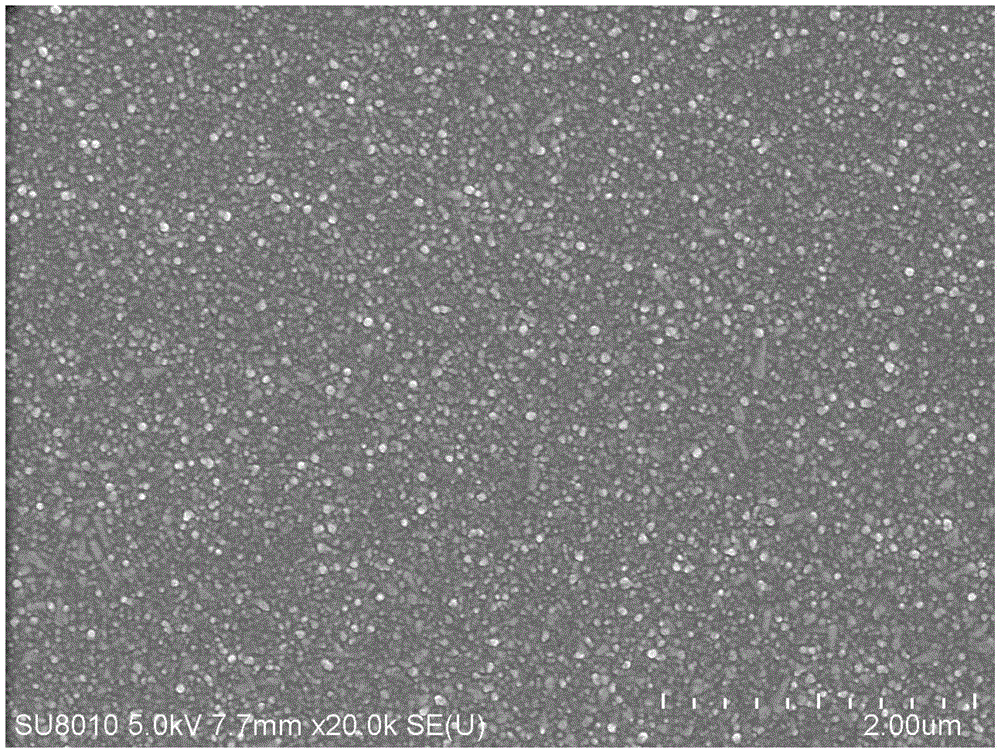

[0045] (3) With the rotating speed of 3000rpm, the PbI that concentration is 462mg / mL 2 The DMF solution was spin-coated on the interface modification layer, then heated at 70°C for 30min, cooled naturally, placed in a petri dish, and evenly sprinkled with 0.25g of CH 3 NH 3 1 powder; then put it into a vacuum drying oven, and at a pressure of 10KPa and a temperature of 150°C, react for 30min to generate a perovskite; after natural cooling, use isopropanol to clean, and heat at 150°C for 5min, Obtain a perovskite light absorbing layer;

[0046] (4) Spin-coat the Spiro-OMeTAD solution on t...

Embodiment 2

[0050] (1) At a speed of 3000rpm, the TiO 2 The solution was spin-coated on a clean FTO substrate and heated at 550°C for 25 minutes to obtain a barrier layer;

[0051] (2) With the rotating speed of 1500rpm, the concentration is 2mg / ml C 60 O-dichlorobenzene solution was spin-coated on the barrier layer, and then heated at 60°C for 2 minutes to obtain an interface modification layer;

[0052] (3) With the rotating speed of 3000rpm, the PbI that concentration is 462mg / mL 2 The DMF solution was spin-coated on the interface modification layer, then heated at 70°C for 30min, cooled naturally, placed in a petri dish, and evenly sprinkled with 0.25g of CH 3 NH 3 1 powder; then put it into a vacuum drying oven, and at a pressure of 5KPa and a temperature of 150°C, react for 30min to generate a perovskite; after natural cooling, use isopropanol to clean, and heat at 150°C for 5min, Obtain a perovskite light absorbing layer;

[0053] (4) Spin-coat the Spiro-OMeTAD solution on the...

Embodiment 3

[0057] (1) At a speed of 3000rpm, the TiO 2 The solution was spin-coated on a clean FTO substrate and heated at 500°C for 30 minutes to obtain a barrier layer;

[0058] (2) With the rotating speed of 1500rpm, the concentration is 14mg / ml C 60 O-dichlorobenzene solution was spin-coated on the barrier layer, and then heated at 60°C for 2 minutes to obtain an interface modification layer;

[0059] (3) With the rotating speed of 3000rpm, the PbI that concentration is 462mg / mL 2 The DMF solution was spin-coated on the interface modification layer, then heated at 70°C for 30min, cooled naturally, placed in a petri dish, and evenly sprinkled with 0.25g of CH 3 NH 3 1 powder; then put it into a vacuum drying oven, and at a pressure of 20KPa and a temperature of 150°C, react for 30min to generate a perovskite; after natural cooling, use isopropanol to clean, and heat at 150°C for 5min, Obtain a perovskite light absorbing layer;

[0060] (4) Spin-coat the Spiro-OMeTAD solution on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com