Method for preparing super-hydrophobic sponges

A technology of super-hydrophobic sponge and sponge, applied in the field of functional material preparation, can solve the problems of easy change of pH of reaction medium, increase of material preparation cost, low loading of modified layer, etc., and achieve good recyclability, high coverage, and economical efficiency. The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

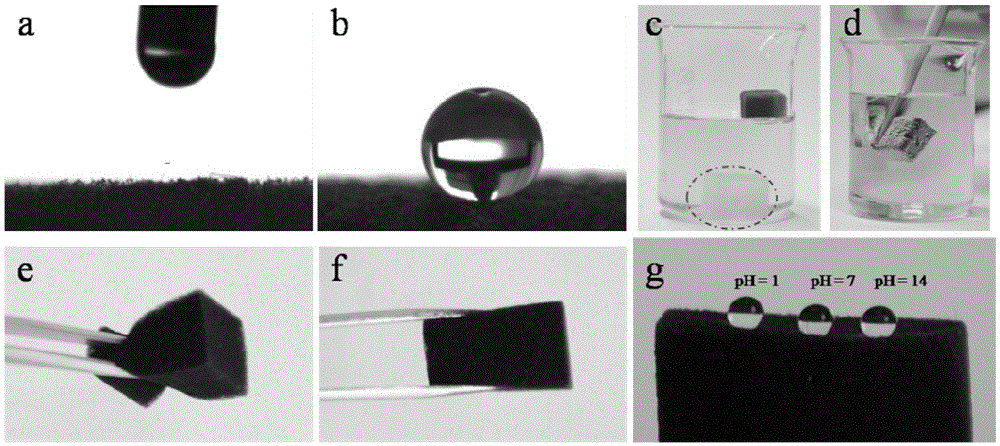

[0034] The melamine resin sponge was modified by two-step low-concentration dopamine solution and covalently bonded with mercapto long-chain alkanes with low surface energy to prepare superhydrophobic sponge. Step (1): melamine resin sponge is soaked in the Tris-HCl buffer solution (pH value is 8.5) that solution concentration is 0.5mol / L, adds dopamine hydrochloride (final concentration is 2.0mg / mL), makes dopamine in The surface of the melamine resin sponge is polymerized, reacted at room temperature for 6h to obtain the melamine resin sponge coated with polydopamine; step (2): soak the melamine resin sponge coated with polydopamine gained in step (1) in water / ethanol / ammonia water medium, Wherein the mixing ratio of water and ethanol is a volume ratio of 4:1; the final concentration of ammonia water is 0.1mol / L, adding concentration is 3.3mg / mL of dopamine hydrochloride and mercaptododecane, so that mercaptododecane accounts for the volume of the mixed solution The percenta...

Embodiment 2

[0040] The melamine resin sponge was modified by two-step low-concentration dopamine solution and covalently bonded with mercapto long-chain alkanes with low surface energy to prepare superhydrophobic sponge. Step (1): melamine resin sponge is soaked in the Tris-HCl buffer solution (pH value is 8.5) that solution concentration is 0.2mol / L, adds dopamine hydrochloride (concentration is 1.0mg / mL), makes dopamine in melamine The surface of the resin sponge is polymerized, and reacted at room temperature for 10h to obtain a melamine resin sponge coated with polydopamine; step (2): soak the melamine resin sponge coated with polydopamine gained in step (1) in water / ethanol / ammonia water medium, wherein The mixing ratio of water and ethanol is 2:1 by volume; the final concentration of ammonia water is 0.2mol / L, and dopamine hydrochloride and mercaptododecane are added with a concentration of 4.0mg / mL, so that mercaptododecane accounts for 100% of the volume of the mixed solution. con...

Embodiment 3

[0043] The melamine resin sponge was modified by two-step low-concentration dopamine solution and covalently bonded with mercapto long-chain alkanes with low surface energy to prepare superhydrophobic sponge. Step (1): melamine resin sponge is soaked in the Tris-HCl buffer solution (pH value is 8.5) that solution concentration is 0.4mol / L, adds dopamine hydrochloride (concentration is 1.5mg / mL), makes dopamine in melamine The surface of the resin sponge is polymerized, reacted at room temperature for 5h to obtain a melamine resin sponge coated with polydopamine; step (2): soak the melamine resin sponge coated with polydopamine gained in step (1) in water / ethanol / ammonia water medium, wherein The mixing ratio of water and ethanol is a volume ratio of 3:1; the final concentration of ammonia water is 0.1mol / L, and dopamine hydrochloride and mercaptododecane with a concentration of 3.0mg / mL are added so that mercaptododecane accounts for 100% of the volume of the mixed solution. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com