Preparation method of sulfonate type gemini surfactant

A Gemini-surface, sulfonate-type technology, applied in the preparation of sulfonates, ethers, and esters to prepare ethers, etc., can solve the problems that the yield of intermediates cannot be further improved and the reaction temperature is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

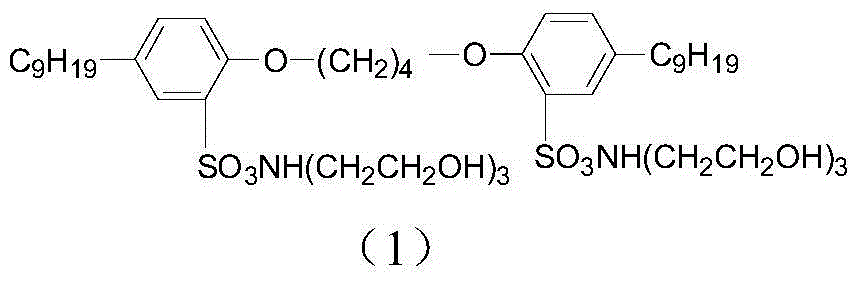

Embodiment 1

[0020] Step 1: In a 250mL four-necked flask equipped with a reflux condenser and a thermometer, add 2.02mol (22.22g) of nonylphenol and 2.00g of tetrabutylammonium bromide, and then add 100mL of 20% sodium hydroxide Aqueous solution, mechanical stirring, turn on the ultrasonic cleaner, set the power to 250W. Set the temperature, when the temperature rises to 55°C, add 0.05mol 1,4-dibromobutane, continue to heat up to 65°C, use thin-layer chromatography to track the reaction process during the reaction, the developer is V (petroleum ether): V (acetic acid ethyl ester)=15:1. After 1.5 hours of reaction, the reaction was completed. The product separated into two phases. After the system was cooled to room temperature, it was extracted with ether (50 mL×3), and the extract was washed with deionized water (50 mL×3), and then dried over anhydrous magnesium sulfate overnight. Suction filtration under reduced pressure and evaporation of the solvent to obtain the bis-ether intermedi...

Embodiment 2

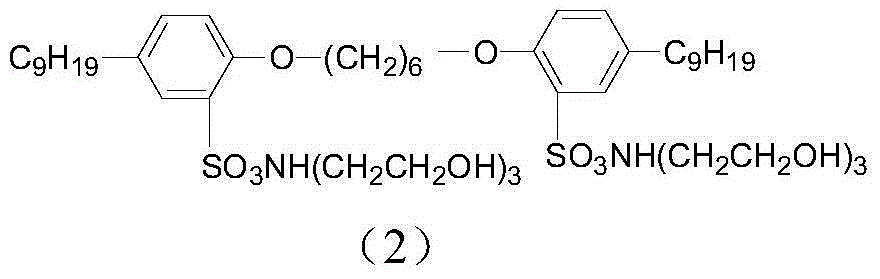

[0024] Step 1: In a 250mL four-necked flask equipped with a reflux condenser and a thermometer, add 2.02mol (22.22g) of nonylphenol and 2.00g of tetrabutylammonium bromide, and then add 100mL of 20% sodium hydroxide Aqueous solution, mechanical stirring, turn on the ultrasonic cleaner, set the power to 250W. Set the temperature, when the temperature rises to 55°C, add 0.05mol 1,6-dibromohexane, continue to heat up to 65°C, use thin-layer chromatography to track the reaction process during the reaction, the developer is V (petroleum ether): V (acetic acid ethyl ester)=15:1. After 1.5 hours of reaction, the reaction was completed. The product separated into two phases. After the system was cooled to room temperature, it was extracted with ether (50 mL×3), and the extract was washed with deionized water (50 mL×3), and then dried over anhydrous magnesium sulfate overnight. Suction filtration under reduced pressure and evaporation of the solvent to obtain the bis-ether intermedi...

Embodiment 3

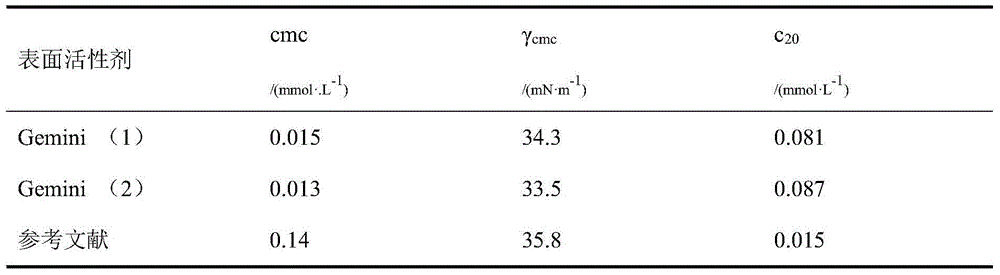

[0027] Embodiment 3 (effect example)

[0028] The HLB value can be used to measure the emulsification effect of the emulsifier. The formula for calculating the HLB value by the structure factor method: HLB=7+∑hydrophilic base number-∑lipophilic base number. The HLB value of the target product in Example 1 can be obtained by substituting the group numbers of the HLB values of the hydrophilic group and the lipophilic group into the formula. HLB=7+9.4×2+1.9×6+1.3×2-34×0.475-2×1.662=20.326.

[0029] Compound the target product in Example 1 with Span80 to emulsify methyl silicone oil. It can be seen from relevant data that the HLB value required for methyl silicone oil to form a stable O / W emulsion is 10.5. It can be seen from the calculation that the mass ratio of the target product to Span80 in Example 1 is 39:61.

[0030] Add 20g of the prepared compound emulsifier and 340ml of water into a large beaker. After the emulsifier is completely dissolved, turn on the high-shear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com