Preparation method and application of porous alumina/zirconia composite support co-im-mim membrane

A porous alumina, composite carrier technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of high cost, high temperature resistance industrial applications, etc., to achieve good separation performance, good thermal stability performance, film making Simple and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

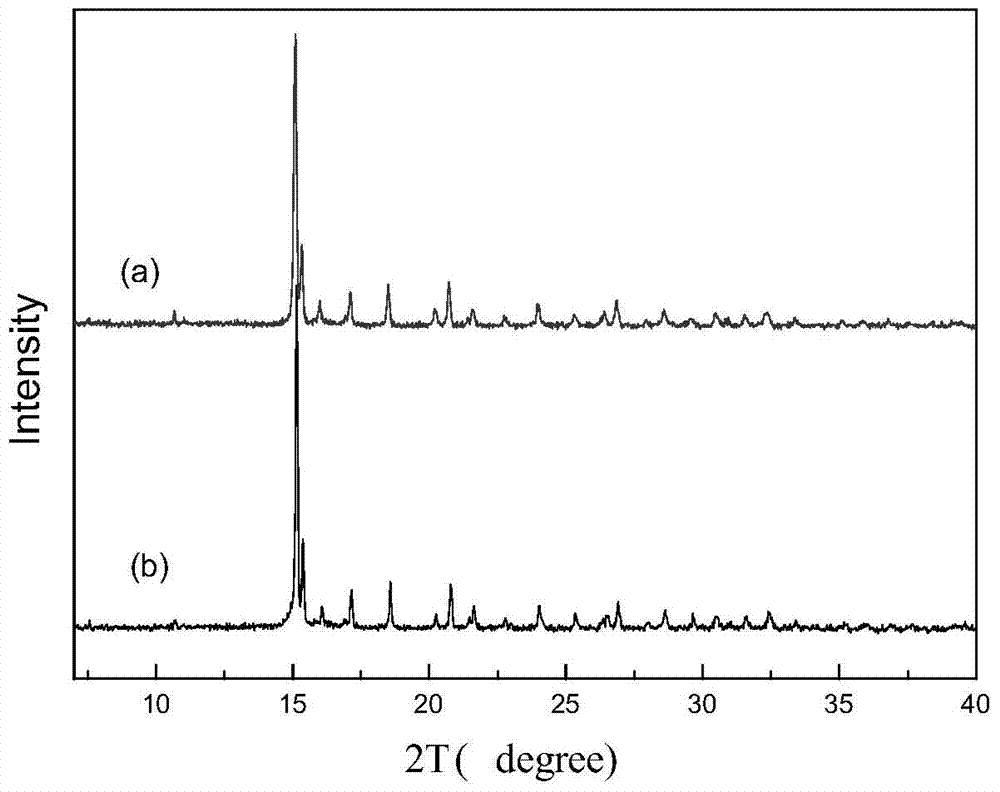

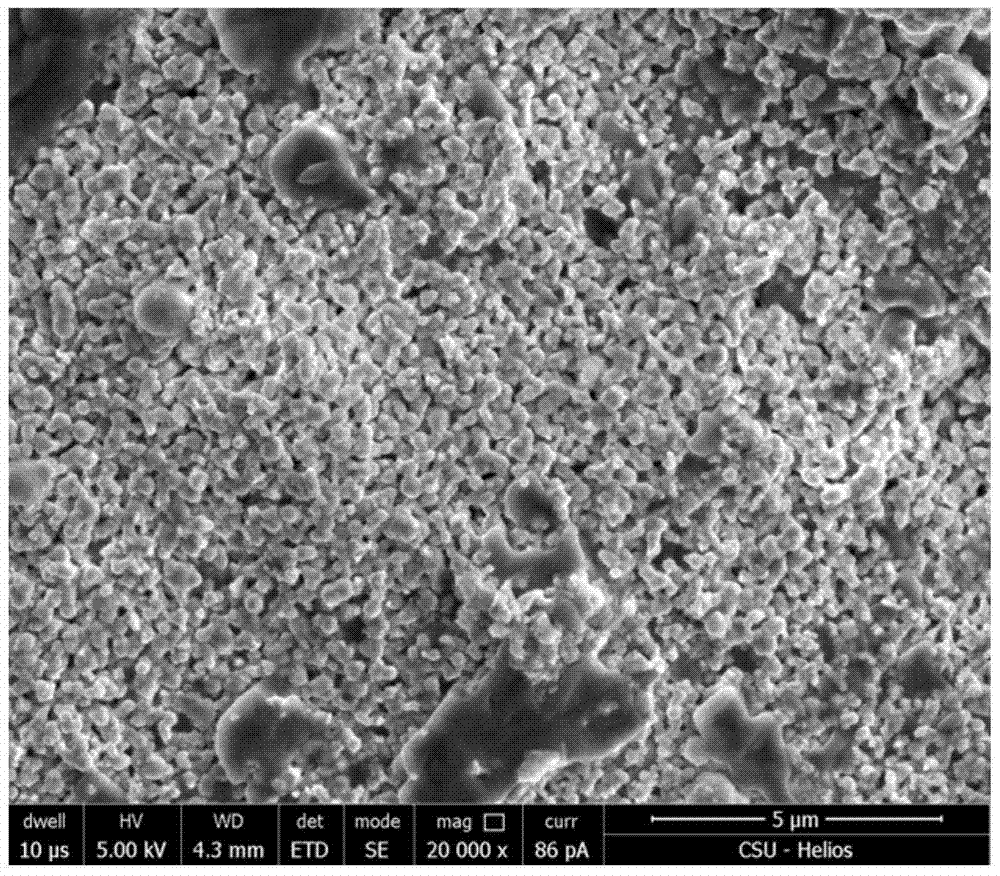

[0040] Zirconia particles with a particle size distribution of 20-500n were added to a stabilizer to form an acetone suspension with a mass content of 4wt%, and the zirconia was introduced into the porous alumina carrier by the pulling method, and the pulling time was 30s. After being dried under high temperature, put it into a muffle furnace at 600°C and bake for 4 hours to obtain a porous alumina / zirconia composite carrier;

[0041] Dissolve 2.32g of metal salt cobalt nitrate, 2.6g of dimethylimidazole, and 2g of imidazole in 350ml of methanol, stir and react at 25°C for 12 hours, and separate by filtration to obtain metal organic framework CO-IM-mIM seed crystals;

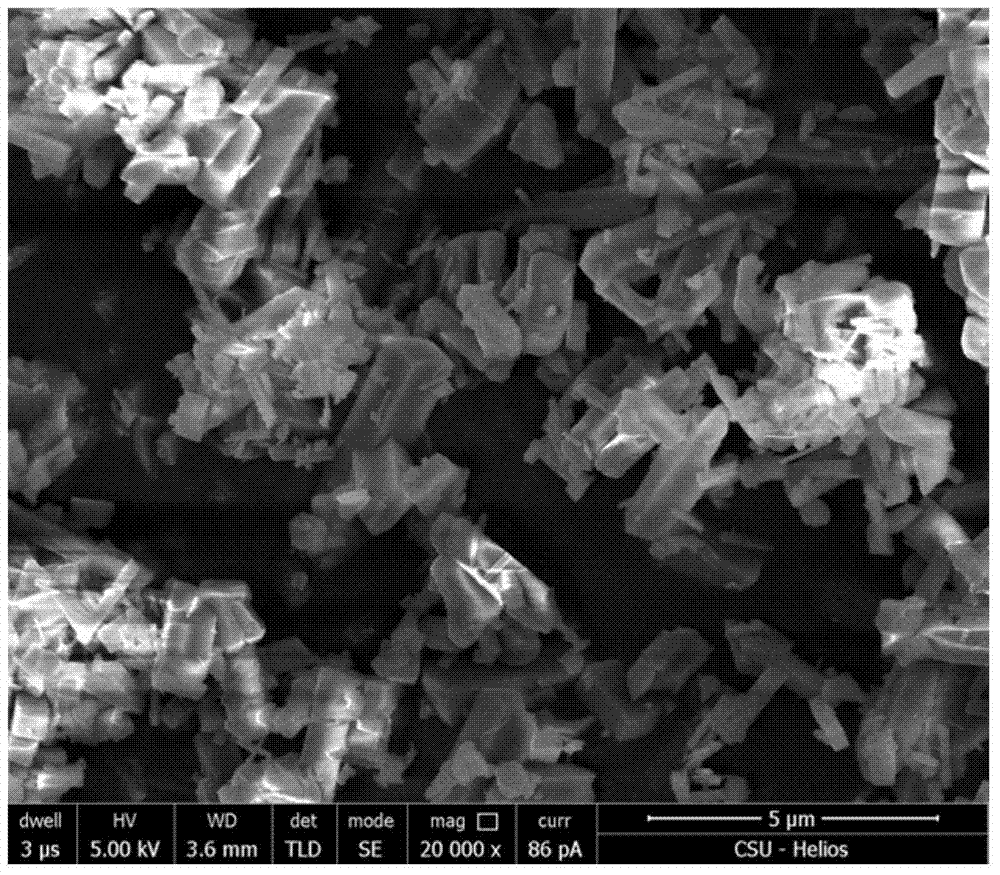

[0042]The porous alumina / zirconia composite carrier was seeded by pulling method in 4wt% CO-IM-mIM methanol solution, the number of pulling was 4 times, and the time of keeping the carrier in the seed liquid was 30 seconds during each pulling , after each pulling, the carrier is dried at 60°C for 6 hours before ...

Embodiment 2

[0052] Zirconia particles with a particle size distribution of 20-500n were added with a stabilizer to form an acetone suspension with a mass content of 4wt%, and the zirconia was introduced into the porous alumina carrier by the pulling method, and the pulling time was 30s. After being dried under high temperature, put it into a muffle furnace at 600°C and bake for 4 hours to obtain a porous alumina / zirconia composite carrier;

[0053] Dissolve 2.32g of metal salt cobalt nitrate, 2.6g of dimethylimidazole, and 2g of imidazole in 350ml of methanol, stir and react at 25°C for 12 hours, and separate by filtration to obtain metal organic framework CO-IM-mIM seed crystals;

[0054] The porous alumina / zirconia composite carrier is seeded by pulling method in 2wt% CO-IM-mIM methanol solution, the number of pulling is 4 times, and the time of keeping the carrier in the seed liquid is 30 seconds during each pulling , after each pulling, the carrier is dried at 60°C for 6 hours before ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com