A kind of preparation method of MNO2/porous carbon film/nickel composite material

A technology of composite materials and porous carbon, which is applied in hybrid capacitor electrodes, structural parts, electrical components, etc., can solve the problems of complex preparation process, harsh experimental conditions, and fragile films, and meet the requirements of low environmental conditions and high product quality. Stable, easily repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

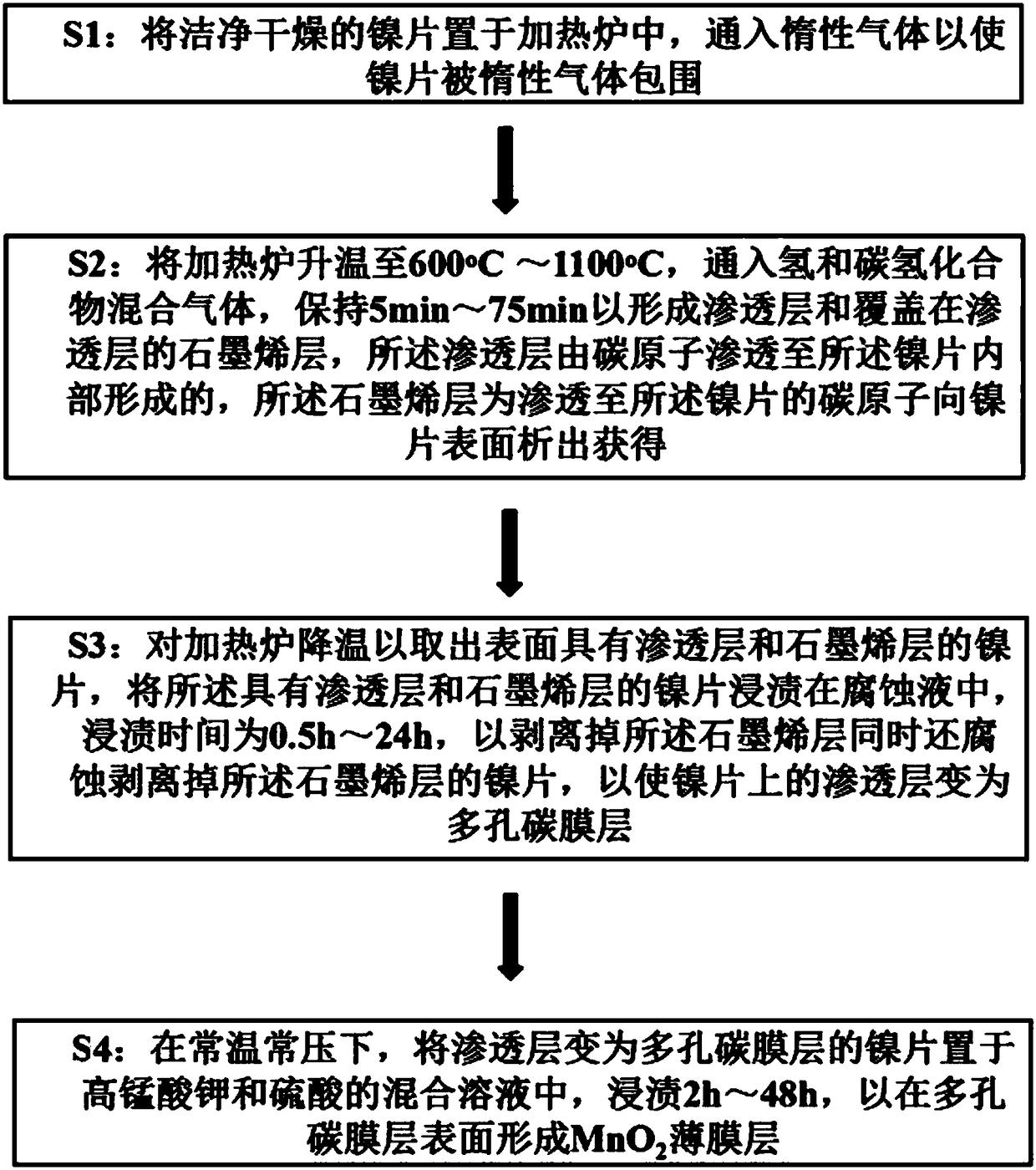

[0037] figure 1 It is the integrated MnO provided by the embodiment of the present invention 2 The realization flowchart of / PCF / Ni composite material preparation method, as can be seen from the figure, the inventive method comprises the steps:

[0038] S1: Place the clean and dry nickel sheet in a heating furnace, and pass in an inert gas so that the nickel sheet is surrounded by an inert gas; the inert gas is at least one of argon or helium, and the flow rate of the inert gas is 50 sccm ~500 sccm.

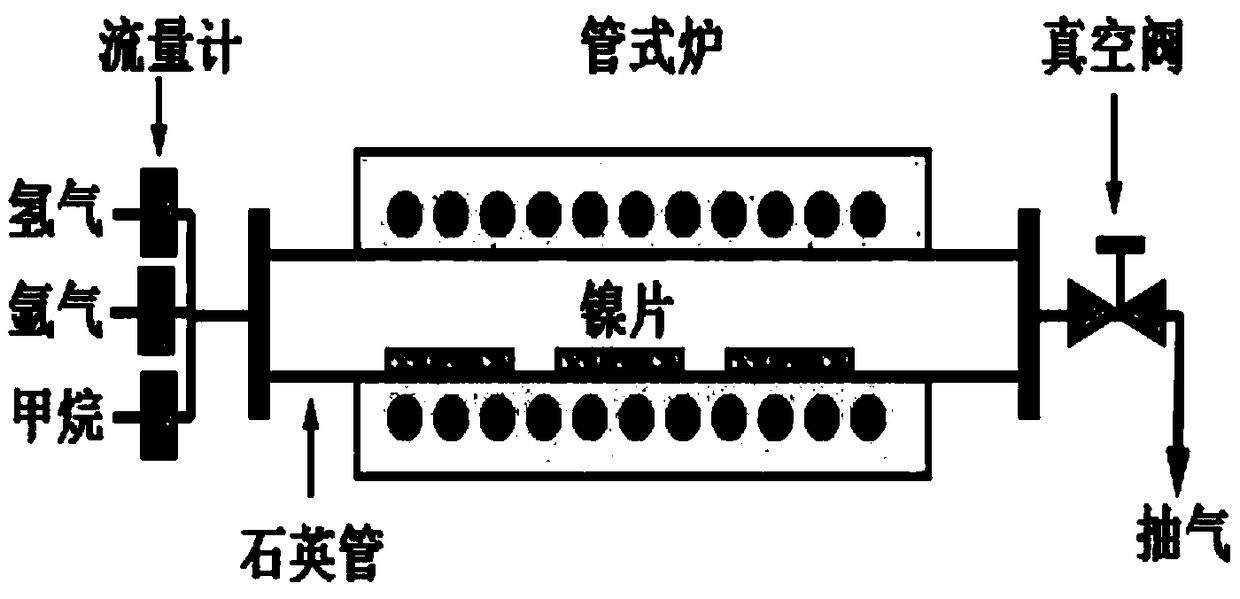

[0039] S2: Raise the temperature of the heating furnace to 600°C to 1100°C, pass in the mixed gas of hydrogen and hydrocarbon, and keep it for 5min to 75min to form a permeable layer and a graphene layer covering the permeable layer, the permeable layer is made of carbon atoms infiltrated into Formed inside the nickel sheet, the graphene layer is obtained by the precipitation of carbon atoms permeated into the nickel sheet to the surface of the nickel sheet; the hydrocarbons ar...

Embodiment 1

[0051] S1: Put the clean and dry nickel sheet in a heating furnace, and pass in an inert gas so that the nickel sheet is surrounded by the inert gas. The inert gas is argon, and the flow rate of the inert gas is 500 sccm.

[0052] S2: Raise the temperature of the heating furnace to 1100°C, feed the mixed gas of hydrogen and hydrocarbons, and keep it for 75 minutes to form a permeable layer and a graphene layer covering the permeable layer, and the permeable layer is made of carbon atoms permeated into the interior of the nickel sheet Formed, the graphene layer is obtained by the precipitation of carbon atoms permeated into the nickel sheet to the surface of the nickel sheet. The hydrocarbon is a kind of methane. The flow rate of the hydrogen is 100 sccm. The flow rate of the hydrocarbons is 500 sccm.

[0053] S3: Cool down the heating furnace to take out the nickel sheet with a permeable layer and a graphene layer on the surface, and immerse the nickel sheet with a permeabl...

Embodiment 2

[0063] S1: The clean and dry nickel sheet is placed in a heating furnace, and an inert gas is introduced so that the nickel sheet is surrounded by the inert gas; the inert gas is helium, and the flow rate of the inert gas is 200 sccm.

[0064] S2: Raise the temperature of the heating furnace to 1000°C, feed a mixed gas of hydrogen and hydrocarbon, and keep it for 50 minutes to form a permeable layer and a graphene layer covering the permeable layer, the permeable layer is permeated by carbon atoms into the interior of the nickel sheet Formed, the graphene layer is obtained by the precipitation of carbon atoms penetrating into the nickel sheet to the surface of the nickel sheet; the hydrocarbon is ethane. The flow rate of the hydrogen is 80 sccm. The flow rate of the hydrocarbons is 400 sccm.

[0065] S3: Cool down the heating furnace to take out the nickel sheet with a permeable layer and a graphene layer on the surface, and immerse the nickel sheet with a permeable layer and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com