Neodymium iron boron magnet raw material powder and treatment process therefor

A treatment process, NdFeB technology, applied in the field of NdFeB magnet raw material powder and its treatment process, can solve the problems of limiting the application of Nd-Fe-B materials, poor corrosion resistance of magnet materials, etc., to improve oxidation resistance, Effect of improving corrosion resistance and high magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

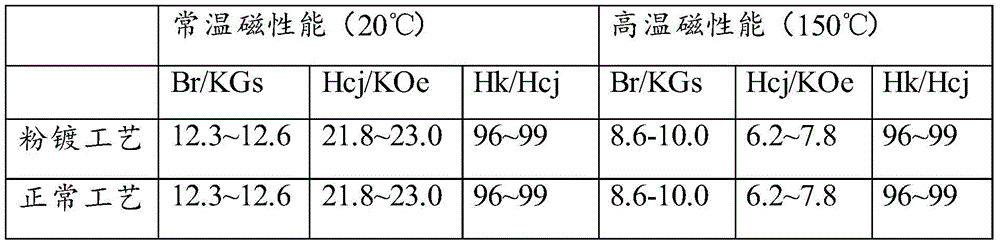

[0046] The verification is done with 38SH sintered NdFeB material, the raw material composition is shown in Table 1 below:

[0047] the element

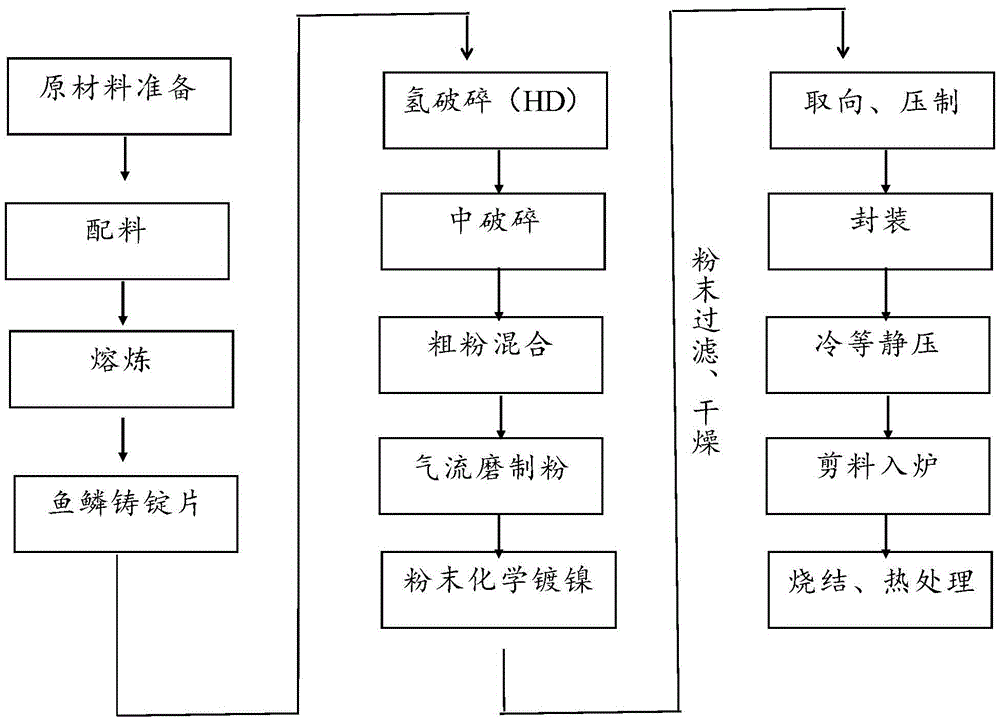

[0048]First, according to the above formula, 600Kg of raw materials are prepared, among which iron rods are derusted, rare earth materials are treated without oil, moisture and rust, and the prepared raw materials are melted under the condition of medium frequency induction heating by vacuum smelting (SC) , and finally obtain a sheet-shaped fast-quenching NdFeB alloy with a columnar crystal structure.

[0049] Then, hydrogen absorption and dehydrogenation are carried out in the hydrogen breaking furnace to break into millimeter-sized coarse particles, and the secondary crusher further breaks the particles, and then through the jet mill with high-pressure nitrogen to grind out micron-sized powder with uniform particle size, and the average particle size of the powder is 4.0-5.0 μm.

[0050] Then carry out electroless nickel ...

Embodiment 2

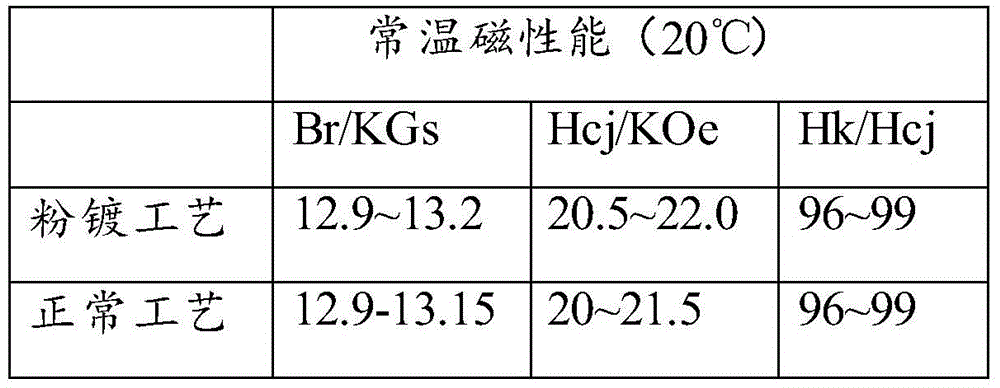

[0080] The verification is done with 42SH sintered NdFeB material, the raw material composition is shown in Table 6 below:

[0081] the element

[0082] First, according to the above formula, 600Kg of raw materials are prepared, among which iron rods are derusted, rare earth materials are treated without oil, moisture and rust, and the prepared raw materials are melted under the condition of medium frequency induction heating by vacuum smelting (SC) , and finally obtain a sheet-shaped fast-quenching NdFeB alloy with a columnar crystal structure.

[0083] Then, hydrogen absorption and dehydrogenation are carried out in the hydrogen breaking furnace to break into millimeter-sized coarse particles. The secondary crusher further breaks the particles, and then passes through the jet mill with high-pressure nitrogen to grind out micron-sized powder with uniform particle size. The average particle size of the powder is 3.7-4.7 μm.

[0084] Then carry out electroless nickel ...

Embodiment 3

[0114] The verification is done with 45UH sintered NdFeB material, the raw material composition is shown in Table 11 below:

[0115] the element

[0116] First, according to the above formula, 600Kg of raw materials are prepared, among which iron rods are derusted, rare earth materials are treated without oil, moisture and rust, and the prepared raw materials are melted under the condition of medium frequency induction heating by vacuum smelting (SC) , and finally obtain a sheet-shaped fast-quenching NdFeB alloy with a columnar crystal structure.

[0117] Then, hydrogen absorption and dehydrogenation are carried out in the hydrogen breaking furnace to break into millimeter-sized coarse particles. The secondary crusher further breaks the particles, and then passes through the jet mill with high-pressure nitrogen to grind out powder with uniform particle size and micron size. The average particle size of the powder is 3.5-4.5 μm.

[0118] Then carry out electroless nic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com