A multilayer structure of barium copper oxide high temperature superconducting coated conductor

A technology of coated conductors and high-temperature superconductivity, applied in superconducting/high-conducting conductors, the usage of superconducting elements, superconducting devices, etc., can solve the problems of element diffusion, secondary phase, holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

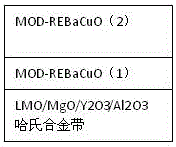

[0019] Example 1, reference figure 2 , A multi-layer structure of barium-copper-oxygen high-temperature superconducting coated conductors, the bottom layer is manganese lanthanum oxide / magnesium oxide / yttrium oxide / aluminum oxide Hastelloy tape, and the top coating is metal organic deposited rare earth barium copper oxide Superconductor layer, the intermediate coating is a metal organic deposited rare earth barium copper oxide superconductor layer, and a metal organic deposited copper oxide layer is sandwiched between the intermediate coating and the bottom layer. The preparation method includes the following steps:

[0020] a. Weigh the organic salts of Re, Ba, Cu according to the molar ratio of RE:Ba:Cu=1:2:3.25, dissolve the organic salts of Ba in deionized water, stir for 10 minutes and add 20% by mass Trifluoroacetic acid solution, continue to stir for 2 hours, evaporate the solvent to obtain trifluoroacetate gel, mix RE and copper organic salt in deionized water and stir f...

Embodiment 2

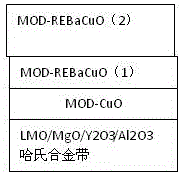

[0025] Example 2, reference image 3 , A multi-layer structure of barium-copper-oxygen high-temperature superconducting coated conductors, the bottom layer is manganese lanthanum oxide / magnesium oxide / yttrium oxide / aluminum oxide / hastelloy strip, and the top coating is metal organic deposits rare earth barium copper oxide The intermediate coating is a metal-organic deposited rare earth barium copper oxide superconductor layer, and a metal-organic deposited copper oxide layer is sandwiched between the intermediate coating and the top coating. The preparation method includes the following steps:

[0026] a. Weigh the organic salts of Re, Ba and Cu according to the molar ratio of RE:Ba:Cu=1:2:3.5, dissolve the organic salts of Ba in deionized water, stir for 30 minutes and add 40% by mass Trifluoroacetic acid solution, continue to stir for 5 hours, evaporate the solvent to obtain trifluoroacetate gel, mix RE and copper organic salt in deionized water and stir for 30 minutes, add 2 t...

Embodiment 3

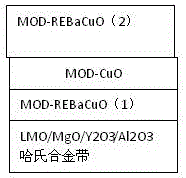

[0031] Example 3, reference figure 2 , A multi-layer structure of barium-copper-oxygen high-temperature superconducting coated conductors, the bottom layer is manganese lanthanum oxide / magnesium oxide / yttrium oxide / aluminum oxide / hastelloy tape, and the top coating is metal organic deposited rare earth barium copper oxide The intermediate coating is a metal-organic deposited rare earth barium copper oxide superconductor layer, and a metal-organic deposited copper oxide layer is sandwiched between the intermediate coating and the bottom layer. The preparation method includes the following steps:

[0032] a. Weigh the organic salts of Re, Ba and Cu according to the molar ratio of RE:Ba:Cu=1:2:3, dissolve the organic salts of Ba in deionized water, stir for 20 minutes and add 30% by mass Trifluoroacetic acid solution, continue to stir for 3 hours, evaporate the solvent to obtain trifluoroacetate gel, mix RE and copper organic salt in deionized water and stir for 20 minutes, add 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com