Hard carbon material preparation method

A hard carbon and raw material technology, which is applied in the preparation/purification of carbon, chemical instruments and methods, carbon compounds, etc., can solve the problem of limiting the performance potential of hard carbon materials, low lithium ion intercalation expansion rate, first Coulombic efficiency and first discharge capacity Poor and other problems, to achieve the effect of providing high-power discharge performance, good stability of particle size and solid content, and superior high and low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

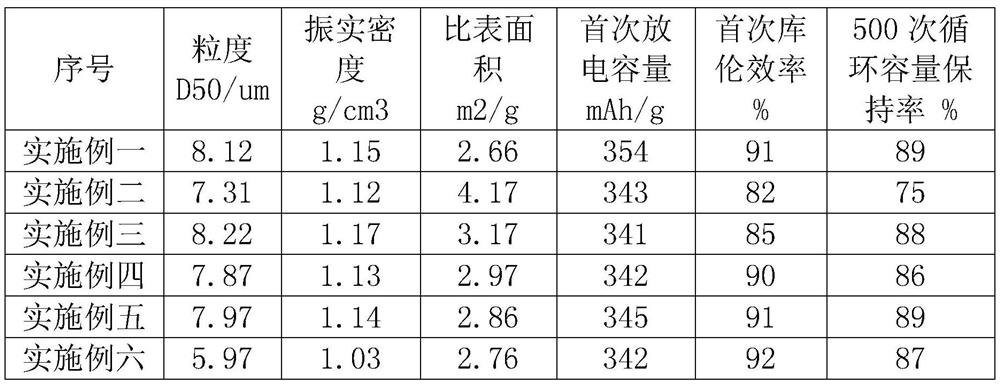

Examples

Embodiment 1

[0023] (1) Put 500g coconut shell in the heating bowl and place it in the atmosphere furnace, feed N2 at 0.1MPa, the flow rate is 200sscm, the temperature is raised to 550C after 30 minutes, and the heating rate is 10C / min. Coconut shell charcoal was formed after 2 hours of heat preservation.

[0024] (2) The prepared coconut shell charcoal is preliminarily pulverized by jet milling until D50 is 7um.

[0025] (3) Put the primary pulverized material into the material bowl, heat it to 1350°C under the protection of N2, the heating rate is 10C / min, and keep it warm for 12 hours to form a hard carbon precursor.

[0026] (4) In a 500mL reactor, add 20g of asphalt, raise the temperature to 165C, stir until the asphalt is completely melted, add 300g of hard carbon precursor, keep stirring at 165C for 2 hours, so that the hard carbon precursor and asphalt are fully mixed, Cool to room temperature;

[0027] (5) Grind the formed lumps with a pair of rollers, and crush them with an air...

Embodiment 2

[0029] Embodiment 2 is consistent with other step parameters of Embodiment 1, and the difference is that the hard carbon material is made without asphalt wrapping. The steps of Embodiment 2 are as follows:

[0030] (1) Put 500g coconut shell in the heating bowl and place it in the atmosphere furnace, feed N2 at 0.1MPa, the flow rate is 200sscm, the temperature is raised to 550C after 30 minutes, and the heating rate is 10C / min. Coconut shell charcoal was formed after 2 hours of heat preservation.

[0031] (2) The prepared coconut shell charcoal is pulverized to a D50 of 7um using airflow.

[0032] (3) Put the pulverized material in the material bowl, heat it to 1150C under the protection of N2, the heating rate is 10C / min, and keep it warm for 12 hours to form a hard carbon material.

Embodiment 3

[0034] Embodiment 3 is consistent with other step parameters of Embodiment 1, the difference being that the heating temperature in step (3) is 1150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com