A composite thermal insulation packaging material

A packaging material and composite technology, applied in the field of packaging materials, can solve the problems of shrinking to the middle, uneven covering thickness of the paper base layer, cracks and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

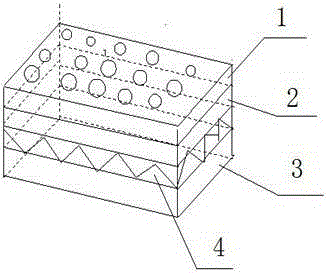

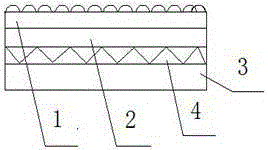

[0013] Such as figure 1 and figure 2 As shown, a composite foam-shaped thermal insulation packaging material of the present invention sequentially includes a flame-retardant PE film 5, a pressure-resistant layer 6, a plastic thermal insulation composite layer 7, and a pressure-resistant layer 8. The polypropylene is polypropylene containing a ceramic catalyst. Composite foam insulation packaging material thickness 2.8-3.5mm, such as figure 2 The uppermost layer is the flame-retardant PE layer 1, followed by the pressure-resistant layer 2, then the plastic thermal insulation composite layer 3, and finally the pressure-resistant layer 4, between the pressure-resistant layer and the plastic thermal insulation composite layer and the pressure-resistant layer and the flame-retardant PE film Both are hydraulically pasted by adhesive, and the combination is firm. During the manufacturing process, the hydraulically plastic thermal insulation composite material will not cause sever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com