A kind of novel derusting liquid and preparation method thereof

A new type of derusting liquid and technology, applied in the field of new derusting liquid and its preparation, can solve the problems of severe corrosion of industrial pipelines, short metal secondary corrosion time, economic loss, etc., to delay secondary corrosion time and improve surface treatment The effect of quality, broad market economic prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

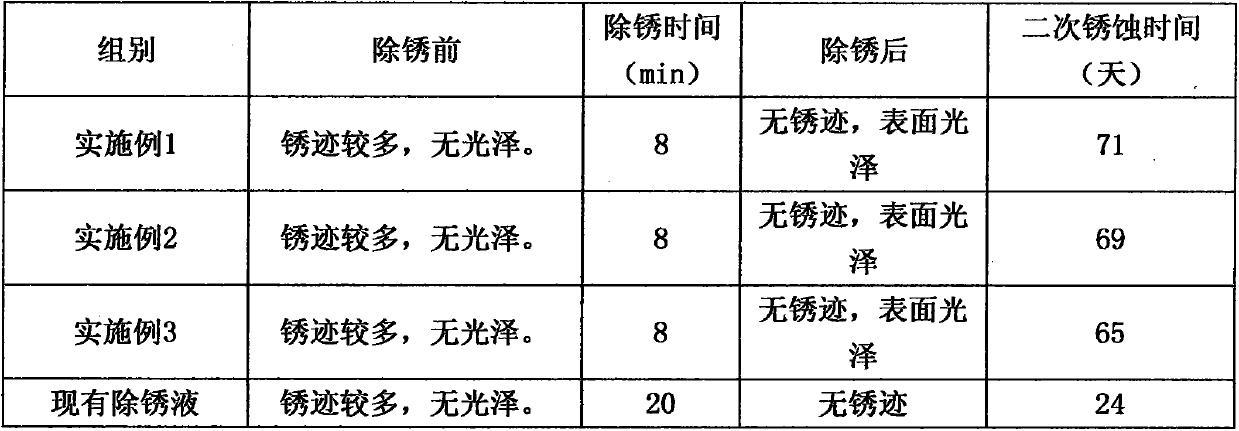

Examples

Embodiment 1

[0021] The novel derusting solution of the present invention comprises the following components calculated by mass percentage: 10% industrial sulfuric acid, 15% hydrochloric acid, 4% citric acid, 2% phosphoric acid, 1% tartaric acid, 5% straw ash, and 2% urotropine , sodium lauryl sulfate 5%, sodium chloride 6%, polyethylene glycol 5%, mesoporous silica 5%, gluconic acid 3%, water-soluble imidazoline 2%, magnesium chloride 5%, lauryl alcohol 3% oxyethylene ether, 1% coconut oil fatty acid, 5% polystyrene microspheres, 2% phenothiazine, and the balance water.

[0022] The preparation method of the above-mentioned derusting liquid includes the following steps: a. Weighing the components according to the parts by mass, first heating the deionized water to 50°C, then adding sodium lauryl sulfate, and stirring for 30 minutes;

[0023] b. Continue heating to 70°C, then add polyoxyethylene lauryl ether, and stir for 20 minutes;

[0024] c, then add industrial sulfuric acid, hydrochl...

Embodiment 2

[0027] The novel derusting solution of the present invention comprises the following components calculated by mass percentage: 15% industrial sulfuric acid, 15% hydrochloric acid, 3% citric acid, 2% phosphoric acid, 1% tartaric acid, 4% straw ash, and 2% urotropine , sodium lauryl sulfate 6%, sodium chloride 7%, polyethylene glycol 5%, mesoporous silica 6%, gluconic acid 3%, water-soluble imidazoline 2%, magnesium chloride 5%, lauryl alcohol 3% oxyethylene ether, 1% coconut oil fatty acid, 3% polystyrene microspheres, 2% phenothiazine, and the balance water.

[0028] Its preparation process is as embodiment 1.

Embodiment 3

[0030] The novel derusting liquid of the present invention comprises the following components calculated by mass percentage: industrial sulfuric acid 15%, hydrochloric acid 10%, citric acid 3%, phosphoric acid 2%, tartaric acid 2%, straw ash 6%, urotropine 2% , sodium lauryl sulfate 5%, sodium chloride 4%, polyethylene glycol 5%, mesoporous silica 5%, gluconic acid 4%, water-soluble imidazoline 4%, magnesium chloride 5%, lauryl alcohol Oxyethylene ether 5%, coconut oil fatty acid 1%, polystyrene microspheres 5%, phenothiazine 2%, and the balance water.

[0031] Its preparation process is as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com