Steel pipe rust removal device

A steel pipe and transmission device technology, which is applied in metal processing equipment, manufacturing tools, grinding feed motion, etc., can solve the problems of great impact on human health, potential safety hazards, and easy rusting of steel pipes, saving working time and improving The effect of work efficiency and fast rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

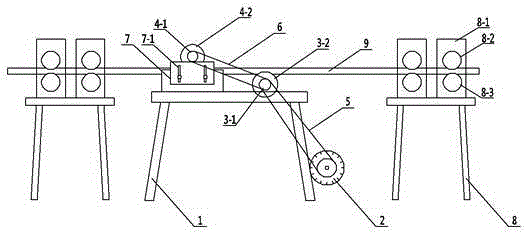

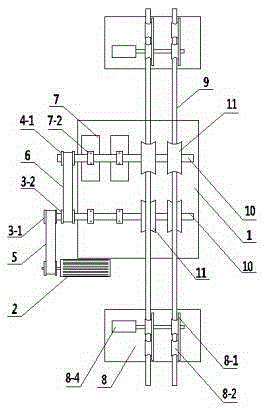

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0021] Steel pipe derusting device, including bracket 1, rust brushing motor 2, rust brushing device I, rust brushing device II and two steel pipe transmission devices, bracket 1 includes a top surface and four feet arranged under the top surface, rust brushing motor 2 Installed on the legs of the bracket 1, the rust brushing device I is set on the top surface of the bracket 1 on the side close to the rust brushing motor 2, and the rust brushing device II is set on the top surface of the bracket 1 on the side away from the rust brushing motor 2, and the steel pipe transmission The device is used to support the steel pipe 9 and transport the steel pipe 9 during the rust brushing process.

[0022] Rust brushing device 1 comprises rotating shaft 10, outer runner 3-1, inner runner 3-2 and wire brush 11, bearing 7-2 is set on the top surface of support 1, and rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com