Round iron bar rust removal device

A technology of iron bars and mounting plates, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc., and can solve the problems of slow grinding speed, unfavorable recycling of round iron bars, and consumption of human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

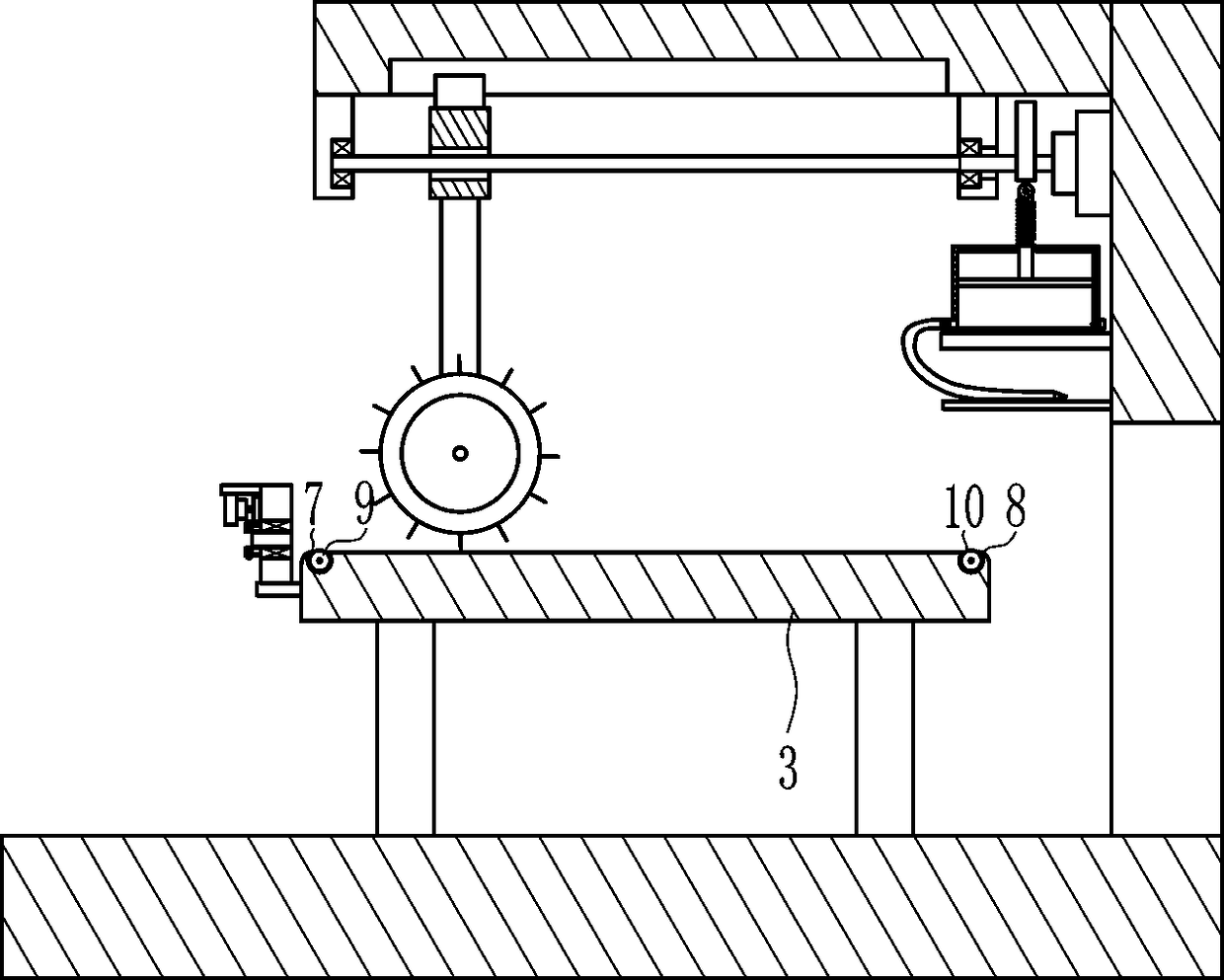

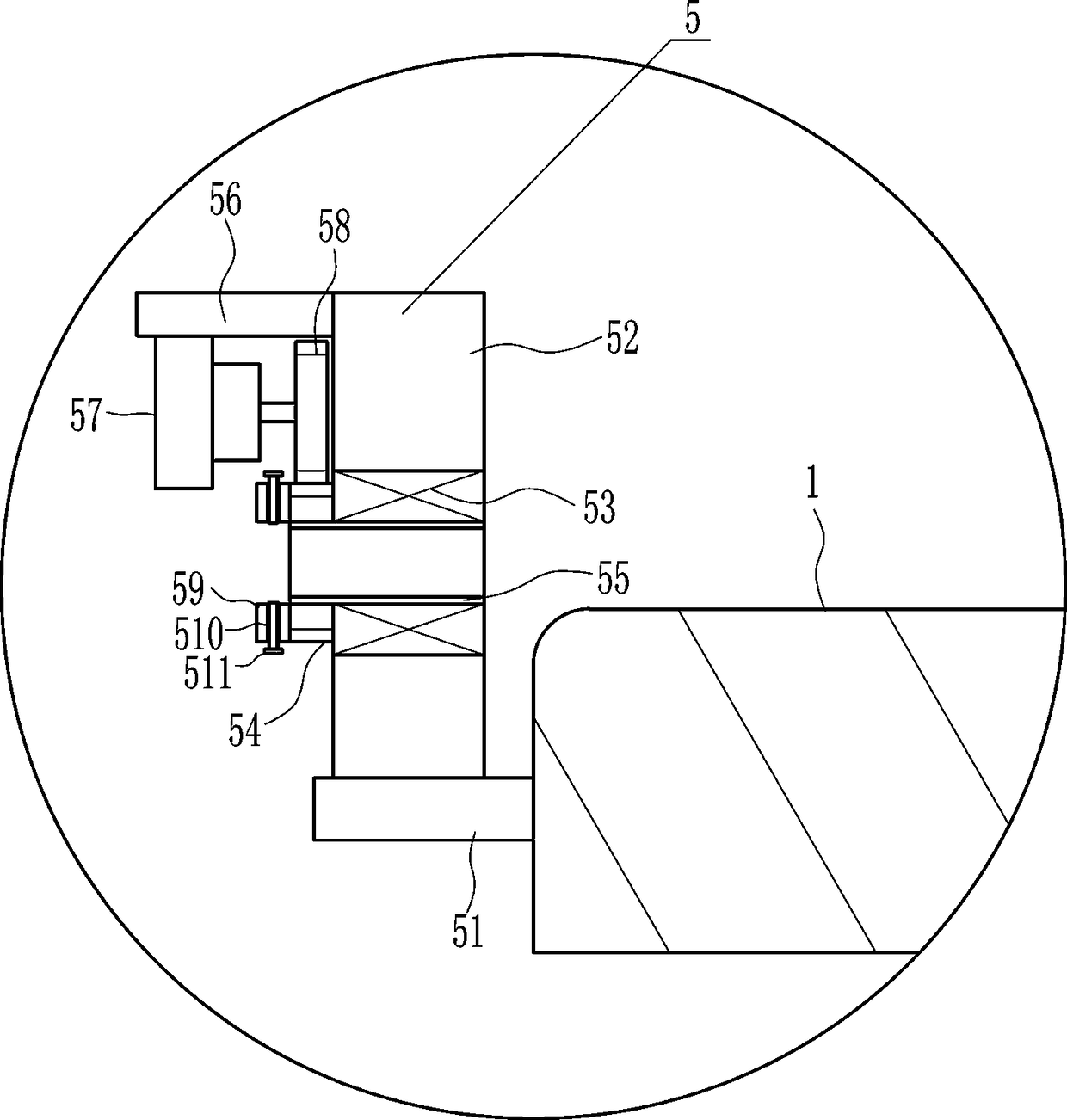

[0028] A round iron bar derusting device, such as Figure 1-5 As shown, it includes a bottom plate 1, a foot 2, a first placement plate 3, a bracket 4, a support plate 42, a slide rail 43, a slider 44, a first mounting plate 45, a second mounting plate 46, a first bearing 47, a Two bearings 48, screw mandrel 410, screw nut 411, first motor 412, connecting plate 413, second motor 414 and derusting wheel 415, the top left and right sides of base plate 1 are fixedly connected with support legs 2 symmetrically, two support legs 2 The top of the top is fixedly connected with the first placement plate 3, the upper right side of the bottom plate 1 is fixedly connected with the support 4, the bottom of the support 4 is provided with the first through hole 41, and the upper left side of the support 4 is fixedly connected with the support plate 42, the support plate The bottom of 42 is provided with slide rail 43, slide rail 43 is fitted with slide block 44, the bottom left side of supp...

Embodiment 2

[0030] A round iron bar derusting device, such as Figure 1-5 As shown, it includes a bottom plate 1, a foot 2, a first placement plate 3, a bracket 4, a support plate 42, a slide rail 43, a slider 44, a first mounting plate 45, a second mounting plate 46, a first bearing 47, a Two bearings 48, screw mandrel 410, screw nut 411, first motor 412, connecting plate 413, second motor 414 and derusting wheel 415, the top left and right sides of base plate 1 are fixedly connected with support legs 2 symmetrically, two support legs 2 The top of the top is fixedly connected with the first placement plate 3, the upper right side of the bottom plate 1 is fixedly connected with the support 4, the bottom of the support 4 is provided with the first through hole 41, and the upper left side of the support 4 is fixedly connected with the support plate 42, the support plate The bottom of 42 is provided with slide rail 43, slide rail 43 is fitted with slide block 44, the bottom left side of supp...

Embodiment 3

[0033] A round iron bar derusting device, such as Figure 1-5 As shown, it includes a bottom plate 1, a foot 2, a first placement plate 3, a bracket 4, a support plate 42, a slide rail 43, a slider 44, a first mounting plate 45, a second mounting plate 46, a first bearing 47, a Two bearings 48, screw mandrel 410, screw nut 411, first motor 412, connecting plate 413, second motor 414 and derusting wheel 415, the top left and right sides of base plate 1 are fixedly connected with support legs 2 symmetrically, two support legs 2 The top of the top is fixedly connected with the first placement plate 3, the upper right side of the bottom plate 1 is fixedly connected with the support 4, the bottom of the support 4 is provided with the first through hole 41, and the upper left side of the support 4 is fixedly connected with the support plate 42, the support plate The bottom of 42 is provided with slide rail 43, slide rail 43 is fitted with slide block 44, the bottom left side of supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com