Method for rapidly recovering rhenium, copper and lead from copper smelting waste acid and device for implementing method

A copper smelting and fast technology, applied in the field of lead, copper, and rhenium rapid recovery, can solve the problems of long reaction time, high-pressure alkali leaching, high consumption of alkali, equipment scale, large investment, etc. The effect of short and small production investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

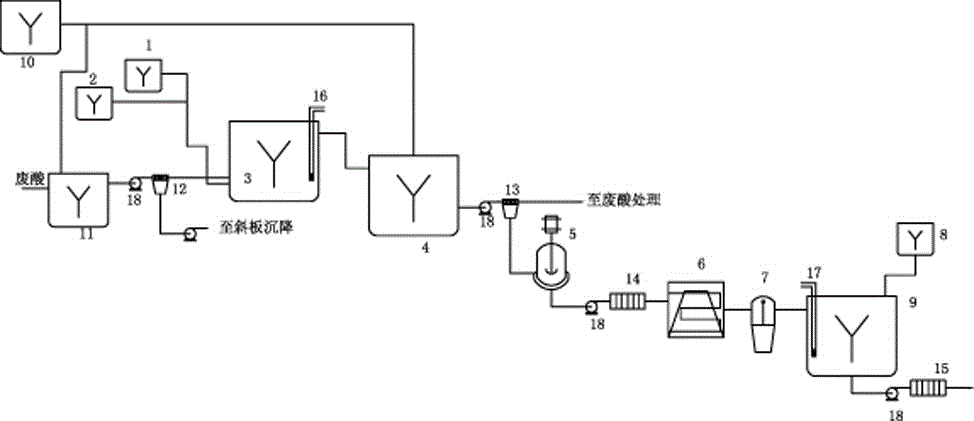

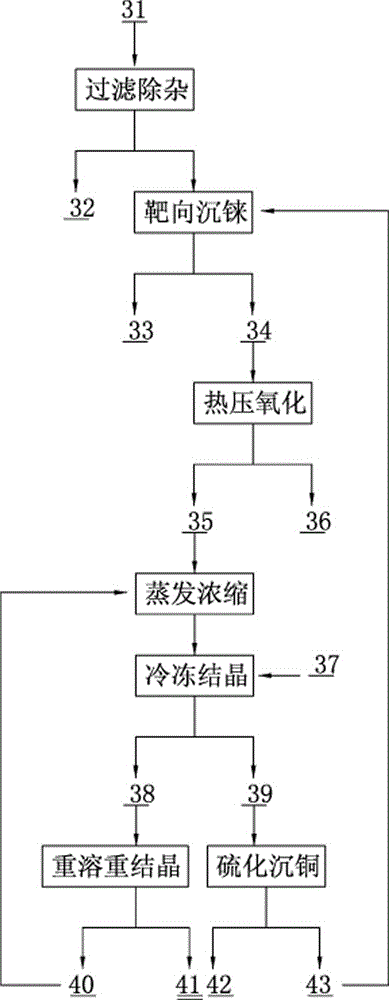

Method used

Image

Examples

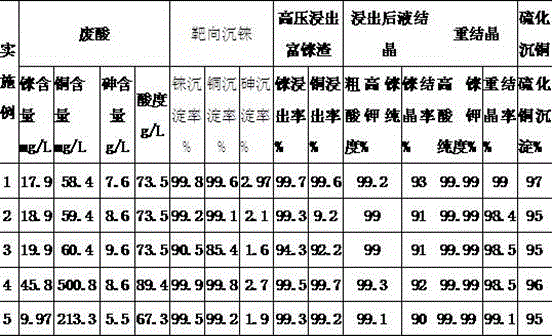

Embodiment 1

[0033] In this example, the sulfuric acid concentration of copper smelting waste acid is 73.48g / L, the rhenium concentration is 17.94mg / L, the copper concentration is 33.48mg / L, and the arsenic concentration is 7.58g / L. The treatment process and effect are as follows:

[0034] (1) The waste acid from copper smelting is filtered by anti-gravity osmosis to remove the lead suspension in the waste acid and send it to the rhenium-copper precipitation tank to obtain the lead slag composition: lead 52.3%, copper 0.1%, bismuth 0.5%, arsenic 0.1%.

[0035] (2) Pump the waste acid after filtering and removing lead to the rhenium-copper precipitation tank, and use a metering pump at a rate of 1m 3 Add 20L of 20% sodium thiosulfate and 15g of sodium sulfide to the waste acid, heat it with steam to 70°C, and stir for 5 minutes; the obtained rhenium-rich slag contains 2.56% rhenium, 32.18% arsenic, and 8.34% copper; the rhenium precipitation rate is 99.8%, The arsenic precipitation rate is ...

Embodiment 2

[0039] In this example, the sulfuric acid concentration of copper smelting waste acid is 73.48g / L, the rhenium concentration is 17.94mg / L, the copper concentration is 33.48mg / L, and the arsenic concentration is 7.58g / L. The treatment process and effect are as follows:

[0040] (1) The waste acid from copper smelting is filtered by anti-gravity osmosis to remove the lead suspension in the waste acid and send it to the rhenium-copper precipitation tank to obtain the lead slag composition: lead 52.3%, copper 0.1%, bismuth 0.5%, arsenic 0.1%. (2) Pump the waste acid after filtering and removing lead to the rhenium-copper precipitation tank, and use a metering pump at a rate of 1m 3 Add 25L of 20% sodium thiosulfate and 20g of sodium sulfide to the waste acid, heat it with steam to 65°C, and stir for 15 minutes; the obtained rhenium-rich slag consists of 2.55% rhenium, 22.18% arsenic, and 8.28% copper; the rhenium precipitation rate is 99.2%, The arsenic precipitation rate is only ...

Embodiment 3

[0044] In this example, the sulfuric acid concentration of copper smelting waste acid is 73.48g / L, the rhenium concentration is 17.94mg / L, the copper concentration is 33.48mg / L, and the arsenic concentration is 7.58g / L. The treatment process and effect are as follows:

[0045] (1) The waste acid from copper smelting is filtered by anti-gravity osmosis to remove the lead suspension in the waste acid and send it to the rhenium-copper precipitation tank to obtain the lead slag composition: lead 52.3%, copper 0.1%, bismuth 0.5%, arsenic 0.1%. (2) Pump the waste acid after filtering and removing lead to the rhenium-copper precipitation tank, and use a metering pump at a rate of 1m 3 Add 10L of 20% sodium thiosulfate and 10g of sodium sulfide to the waste acid, heat it with steam to 50°C, and stir for 15 minutes; the obtained rhenium-rich slag consists of 4.06% rhenium, 30.36% arsenic, and 12.46% copper; the rhenium precipitation rate is 90.5%, The arsenic precipitation rate is only...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| crystallization time | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com