Industrial preparation method of quercetagetin

A technology for quercetin marigold and marigold slag, which is applied in the field of industrialized preparation of quercetin marigold, can solve the problems of difficult industrialized production, unmentioned product yield, etc. effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

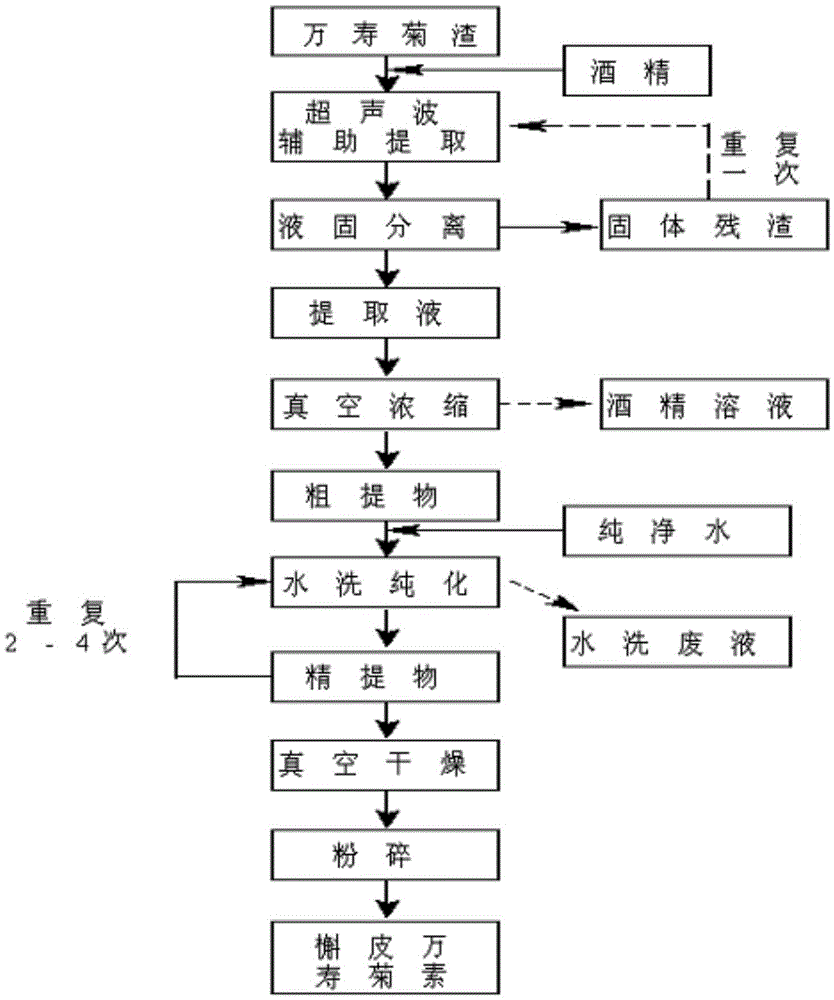

Method used

Image

Examples

Embodiment 1

[0030] 1) Extraction: Weigh 15kg of fermented marigold flower residue, add 100kg of alcohol (70%, v / v) to mix, and stir at room temperature for 30min to form an extraction system; raise the temperature of the extraction system to 60°C, and use ultrasonic waves to assist The extraction method is to extract, the ultrasonic frequency is 20kHz, the ultrasonic power is 400W, the ultrasonic emission frequency is 20s / 2s / 20s, and the extraction time is 2.5h. After the extraction is completed, the quercetin-tagerein crude extract is obtained;

[0031] 2) Centrifugal filtration: centrifuge the obtained quercetin-tagalin crude extract for 400 s in a three-legged centrifuge (300 mesh filter cloth) at a speed greater than 6200 rpm; then perform plate-and-frame filter press on the supernatant, and wash with a small amount of alcohol Plate and frame 3 times to obtain filter cake and quercetin clarified solution;

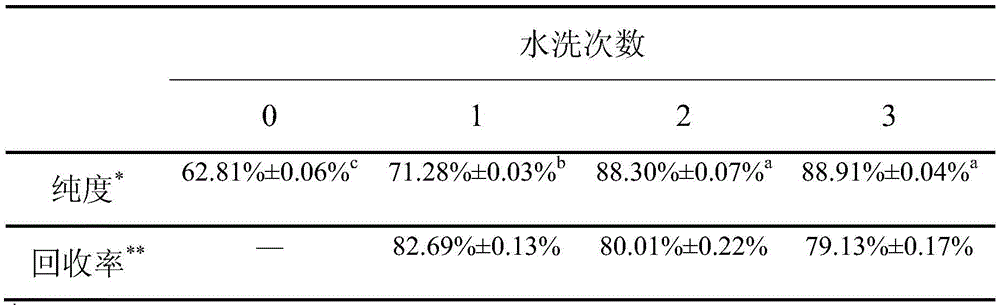

[0032] 3) Concentration: Concentrate the obtained quercetin clarified liquid a...

Embodiment 2

[0040] 1) Extraction: Weigh 15kg of marigold flower residue after extracting lutein, add 100kg of alcohol (60%, v / v) to mix, stir at room temperature for 30min and mix evenly to form an extraction system; heat the extraction system to 50°C , using ultrasonic-assisted extraction method for extraction, the ultrasonic frequency is 20kHz, the ultrasonic power is 400W, the ultrasonic emission frequency is 20s / 2s / 20s, the extraction time is 1h, after the extraction is completed, the quercetin-tagetin crude extract is obtained;

[0041] 2) Centrifugal filtration: centrifuge the obtained quercetin-tagetine crude extract for 500 s in a three-legged centrifuge (300 mesh filter cloth) at a rotation speed greater than 6200 rpm; perform plate-and-frame filter on the supernatant, and use a small amount of alcohol plate-and-frame Washing 3 times to obtain filter cake and quercetin clarified solution;

[0042] 3) Secondary extraction: Add 90kg of alcohol (60%, v / v) to the filter cake and mix ...

Embodiment 3

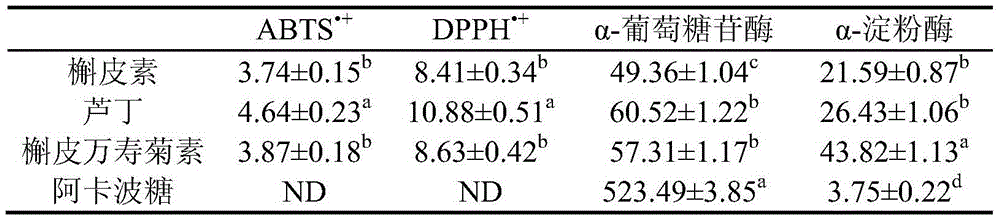

[0046] Example 3: Activity Analysis of Quercetin Tagetes Products

[0047] The quercetin tagetin obtained in Example 1 was subjected to in vitro scavenging of DPPH and ABTS free radicals and inhibition of α-glucosidase and α-amylase, and the results are shown in Table 2. The results showed that, compared with the reference substance, the quercetin tagetin obtained by this method had good antioxidant and inhibitory activities of glucosidase and amylase.

[0048] Table 2: IC of Quercetin Tagetes in Scavenging Free Radicals and Inhibiting Enzyme Activity 50 Value (mg / L)

[0049]

[0050] Note: ND: not determined, there are significant differences in the data with different letters superscripted in the same column (P<0.05).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com