Integrated chlorine dioxide disinfection machine provided with contact disinfection area

A chlorine dioxide, disinfection machine technology, applied in chemical instruments and methods, water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the high accident rate of submersible pumps, physical damage, and shortened life and other problems to achieve the effect of reducing the frequency of accidents, prolonging the service life and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below in conjunction with the accompanying drawings.

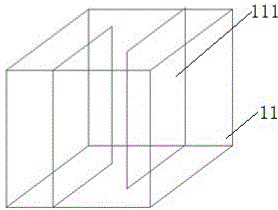

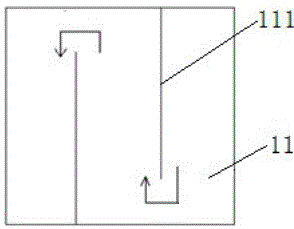

[0016] Such as Figure 1-4 Shown is a preferred embodiment of the invention.

[0017] An integrated chlorine dioxide disinfection machine with a contact disinfection area, including a disinfection cabinet 1, a closed contact disinfection area 11 is arranged in the disinfection cabinet 1, and a disinfectant storage area 12 and a metering pump are arranged on the top of the contact disinfection area 11 Area 13, Metering Pump Area 13 is provided with a metering pump (not shown in the figure), and the disinfectant in the disinfectant storage area 12 is pumped to the contact disinfection area 11 through the metering pump. Flow partition 111, the contact disinfection zone 11 inner wall where one side of the baffle partition 111 is provided with drainage hole 14, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com