A method for preparing spherical tin oxide nanomaterials

A stannous oxide and nanomaterial technology, which is applied in the directions of tin oxide and nanotechnology, can solve the problems of increasing the difficulty of preparing stannous oxide nanomaterials, the purity of the prepared products is not high, and the human body is polluted, so as to achieve low production cost and environmental protection. Friendly, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] To analyze pure SnO 2 (purity 99.5%), SiO 2 (purity 99.5%) and sodium humate as raw materials are respectively ground to -0.074mm particle size and the mass percentage is not less than 80%; 2 :SiO2 2 : Na molar ratio is 1:0.25:0.07 and mixed evenly; put the mixed powder material into CO and CO 2 The composition of the roasting atmosphere is heated and roasted, the roasting temperature is 950°C, and the roasting atmosphere is [CO / (CO+CO 2 )] was 12.5%, the roasting time was 120min, and the roasting flue gas was passed into deionized water with a temperature of 2°C. After the reaction was over, the solution was filtered, dehydrated, and dried to finally obtain high-purity spherical stannous oxide nanomaterials. The SnO content of the product was tested 99.6%, SnO yield 78.5%.

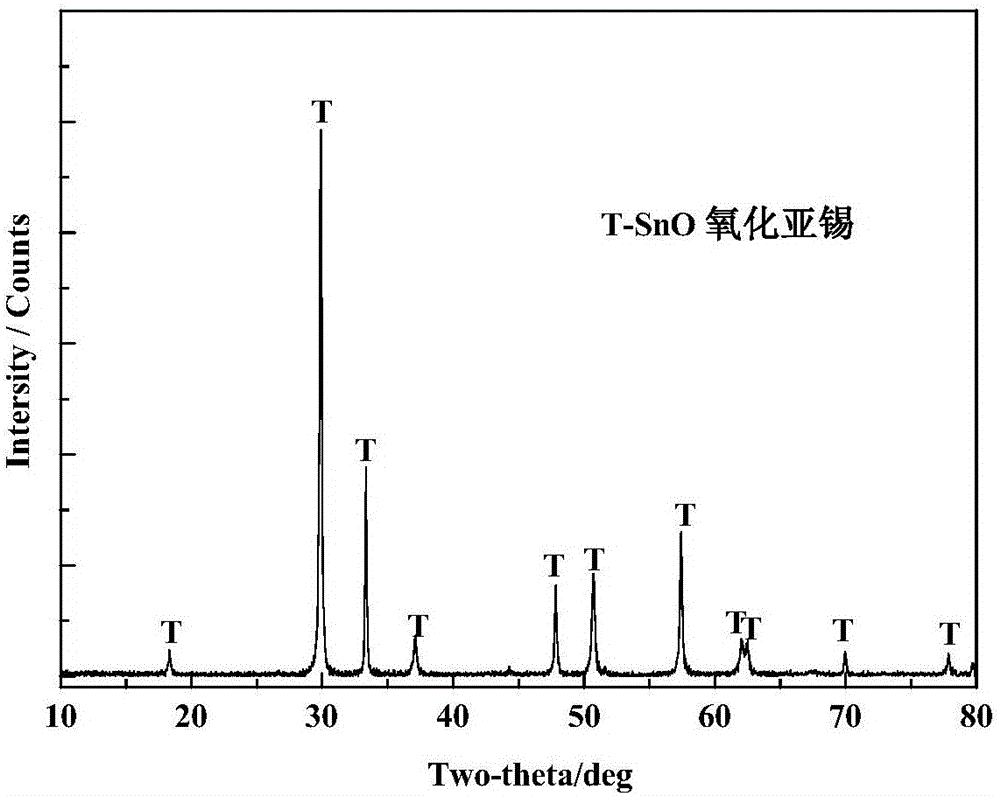

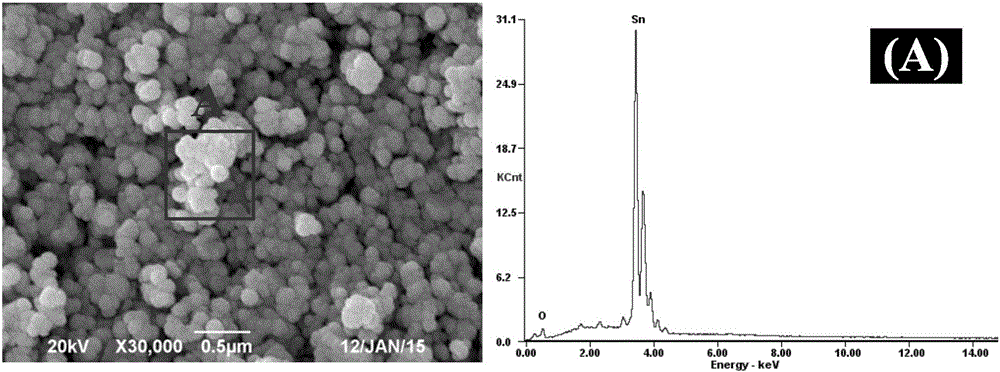

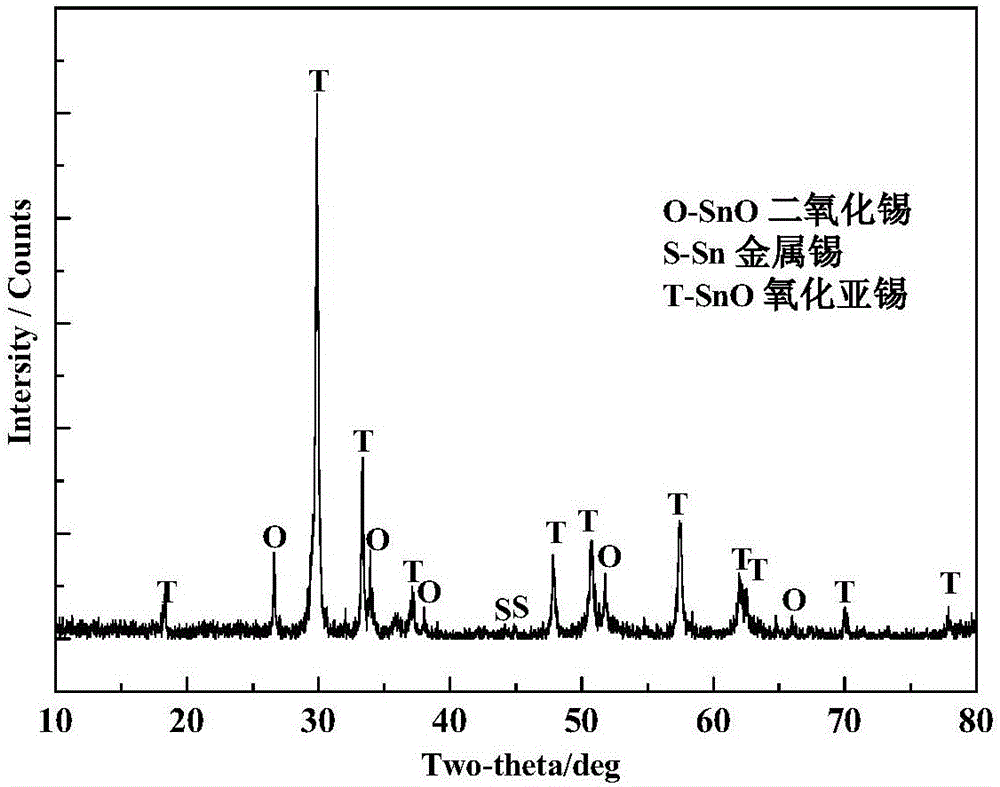

[0024] The XRD result of the prepared product under this condition is shown in the appendix figure 2 , the scanning electron microscope energy spectrum of the product is shown in image 3 . ...

Embodiment 2

[0026] To analyze pure SnO 2 (purity 99.5%), SiO 2 (purity 99.5%) and sodium humate as raw materials are respectively ground to -0.074mm particle size and the mass percentage is not less than 80%; 2 :SiO2 2 : Na molar ratio is 1:0.2:0.08 and mixed evenly; put the mixed powder material into CO and CO 2 Composition of the roasting atmosphere heating and roasting, the roasting temperature is 875 ° C, the roasting atmosphere is [CO / (CO+CO 2 )] was 17.5%, the roasting time was 100min, and the roasting flue gas was passed into deionized water with a temperature of 5°C. After the reaction was over, the solution was filtered, dehydrated, and dried to finally obtain high-purity spherical stannous oxide nanomaterials. The SnO content of the product was tested 99.7%, SnO yield 76.3%; the appearance of the product is uniform spherical particles, and the diameter is in the range of 100-200 nanometers.

Embodiment 3

[0028] To analyze pure SnO 2 (purity 99.5%), SiO 2 (purity 99.5%) and sodium humate as raw materials are respectively ground to -0.074mm particle size and the mass percentage is not less than 80%; 2 :SiO2 2 : Na molar ratio is 1:0.1:0.05 and mixed evenly; put the mixed powder material into CO and CO 2 Composition of the roasting atmosphere heating and roasting, the roasting temperature is 800 ° C, the roasting atmosphere is [CO / (CO+CO 2 )] was 5%, the roasting time was 80min, and the roasting flue gas was passed into deionized water with a temperature of 10°C. After the reaction, the solution was filtered, dehydrated, and dried to finally obtain high-purity spherical stannous oxide nanomaterials. The SnO content of the product was tested 98.5%, SnO yield 73.2%; the product shows that the shape is uniform spherical particles, and the diameter is in the range of 100-200 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com